By David McBride

By David McBride

Director, NASA Dryden Flight Research Center

Over the last several months, I have read many news stories and web accounts about rising and falling fuel prices and how some companies are rediscovering efficiencies by making trucks more aerodynamically efficient. These make me smile as it reminds me of the early aerodynamic truck studies conducted almost 40 years ago at NASA’s Dryden Flight Research Center on Edwards Air Force Base. Fuel efficiency in long haul trucks was never much of an issue until the first peacetime gas crisis, in the early 1970s. In 1973 an aeronautical engineer at NASA Dryden began musing over ways to cut the aerodynamic drag of over-the-road trucks. He led a small team of researchers whose results had an extraordinary, if little recognized, impact.

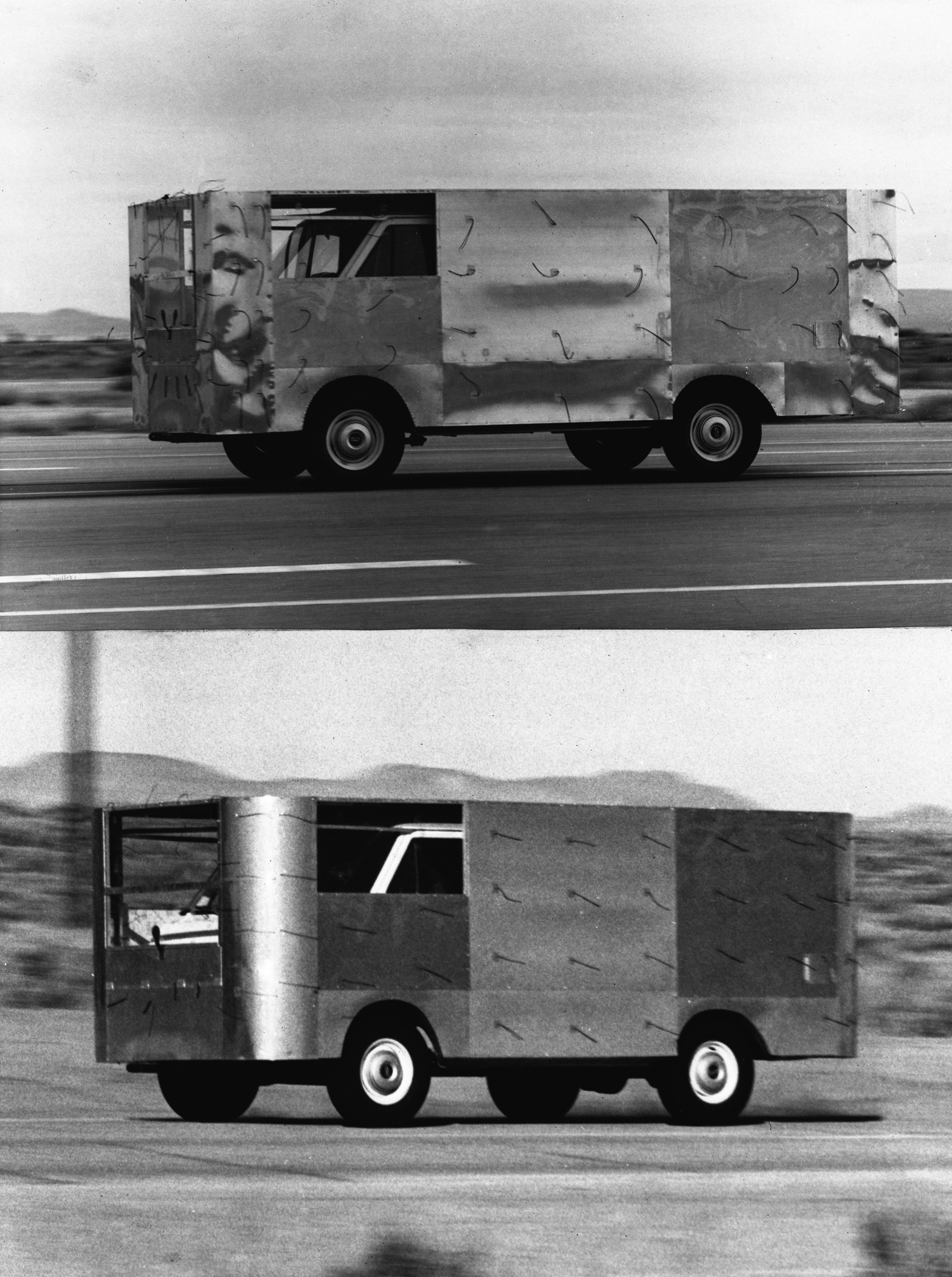

The center’s first experiment involved a passenger van modified into a driving laboratory. We attached an aluminum rectangular box to the vehicle—hence the nickname Shoebox—and over successive experiments, changed elements of the box.We rounded the vertical and horizontal corners, sealed the entire under body including the wheel wells, and even added a “boat tail” to the rear of the vehicle, finding out what benefits each had on the overall aerodynamic drag. Road tests of the Shoebox, with rounded vertical and horizontal corners front and back, lowered the vehicle’s aerodynamic drag by 54percent. Sealing the van’s under body and wheel wells reduced drag another 15percent. Road test showed a mileage increase of between 15 and 25%. Mileage may vary, of course, depending on conditions and styles, which is why Dryden’s engineers were fond of testing outside of wind tunnels.

Image at right: 1970s van fitted with square corners, top image, and round corners bottom. Tufts of yarn attached to the sides of the van indicate air flow around the vehicle.

Our second experiment was conducted on a cab-over-engine tractor-trailer, again modified by rounding all of its front corners and edges. In addition, technicians attached sheet metal fairings over the cab’s roof and sides, reaching as far back as the trailer;this completely closed the open space between the cab and trailer. While still looking like a tractor-trailer, it was a radical departure from anything on theroad in the 1970s. Researchers found that in highway driving at 55 miles perhour, these changes resulted in 20 to 24 percent lower fuel consumption over an identical but unmodified tractor-trailer they tested against it.

At the time of NASA Dryden’s research, which extended off-and-on until 1982, the majority of long-haul tractors were cab-overs. This was because the Federal Aid Highway Act of 1956 – formally known as the National System of Interstate and Defense Highways Act – placed a limit on the length on the total vehicle.

At the time of NASA Dryden’s research, which extended off-and-on until 1982, the majority of long-haul tractors were cab-overs. This was because the Federal Aid Highway Act of 1956 – formally known as the National System of Interstate and Defense Highways Act – placed a limit on the length on the total vehicle.

Image to the left: As depicted by this 1975 image, sheet metal is attached to a heavy haul truck rounding the front corners of the truck and adding a fairing between the cab and the trailer of the truck.

The Surface Transportation Assistance Act (1982), which came primarily in response to the impact of thegas crisis on the trucking industry, required states to permit trucks withtrailers as long as 48 feet on both interstate and intrastate highways, and effectively ignored the tractor altogether. This small detail of the bill was responsible for the shift from cab-overs to conventional engine-in-front tractors, a much more fuel-efficient design because of its shape.

In 1985 Kenworth introduced the T600, the first tractor manufactured with factory-built fairings that reflected the empirical research done at NASA Dryden. It is encouraging to see the continuing improvements to the shapes of both tractors and trailers today, all of which reflect research conducted at Dryden at the time or performed at three universities under Dryden’s guidance.

Hence, when you see fairings that narrow the gap between tractor and trailer, side skirts on the trailer, or boat tails on the back of trailers, you’re looking at the results, in part, of NASA and NASA-sponsored empirical research whose benefits have a tangible impact on our daily lives. It is especially gratifying when I think of the very real increases in fuel efficiency these trucks have realized, and the benefits we all derive as a result