Once upon a time, not that long ago, people used to communicate by what were known as “letters.” These were written documents. Yes, actual hardcopy, paper items. And they were often transcribed by hand or, sometimes, generated on what was known as a “typewriter,” which was basically a manual, analog printer with no I/O port beyond direct keypad entry. These “letters” were sent to their intended recipients using a small denomination currency with an adhesive backing that is recognized for exchange by only one quasi-governmental agency.

I know that some of you may have doubts that people communicated with each other in primitive ways prior to email and text messages, but witness the cultural clues from the 1961 song illustrated above.

It was always believed that the toughest letter to receive was the dreaded “Dear John” letter (as in, “Dear John, I’ve fallen in love with someone else…”). However, I think t’at the hardest letter to write is the “it’s been awhile” letter. This one starts, “Well, it’s been awhile since I’ve written. Sorry.” This blog article is just like one of those letters. It’s been awhile since I’ve written one of these articles and I’m sorry about that. I could give you a big long list of all the really, really serious stuff that I’ve been doing instead, but that’s just a bunch of feeble excuses so I’ll keep them to myself. Instead, I’ll just get down to business and give you a status report on the J-2X development effort.

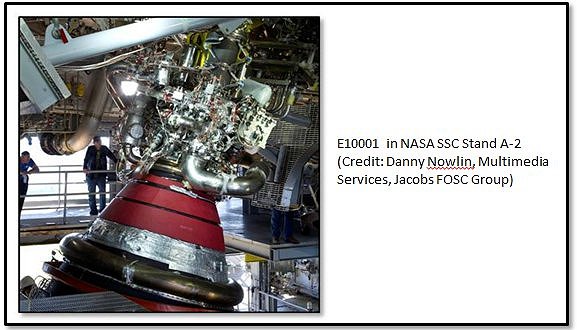

Engine #1 (E10001) Testing is Complete!

Over fourteen months and across the span of twenty-one tests, more than 2,700 seconds of engine run time was accumulated and recorded, including nearly 1,700 seconds of hot fire with an instrumented nozzle extension. With this engine we achieved stable 100% power level operation by the fourth test and full mission duration by the eighth test. While we don’t have any official statistics on the issue, most folks around here believe that we accomplished those milestones faster than has ever been done on a newly developed engine. We learned how to calibrate the engine and the sensitivities that the engine has to different calibration settings, i.e., orifice sizes and valve positions. We were able to estimate performance parameters for the full-configuration of the engine at vacuum conditions and the calculations suggest strongly that all requirements are met by this design and met with substantial margin. This is significant considering that we’ve long considered our performance goals to be pretty aggressive. Well, our little-engine-that-could showed us that it did just fine with those goals, thank you very much.

One of the truly unique and successful aspects of the E10001 testing was the testing of a nozzle extension. This component is a key feature that allows J-2X performance to far exceed that of the J-2 engine from the Apollo Program era. While it is true that we cannot test the full-length nozzle extension without a test stand that actively simulates altitude conditions, we did test a highly instrumented “stub” version that allowed us to characterize the thermal environments to which the nozzle is exposed during engine hot fire and it demonstrated the effectiveness and durability of the emissivity coating that was used. This stub-nozzle configuration is actually the current baseline for the in-development Space Launch System vehicle upper stage.

Another key success for E10001 was the demonstration of both primary and secondary power levels with starts and shutdowns from each power level and with smooth in-run transitions back and forth between them. That smoothness was thanks, in part, to demonstrating our understanding of the control of the engine. From the very first test it was clear that we understood pretty well how to control the engine in terms of proper control orifices for the various operating conditions. What we did not entirely understand — in other words the fine-tuning details — we successfully learned via trial-and-error throughout the E10001 test series. All of this learning has been fed back into further anchoring our analytical tools and models so that we can move forward with J-2X development with a great deal of confidence.

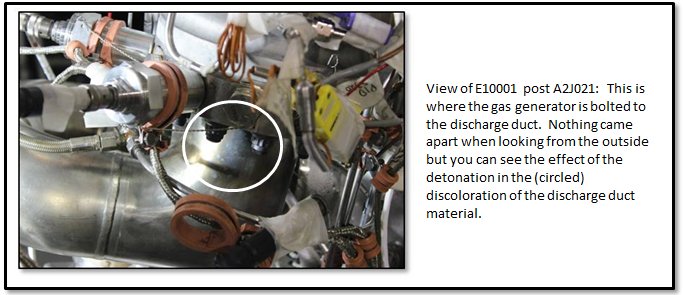

Okay, so that’s a brief description of just some of the good stuff. We had lots and lots of good stuff with the E10001 testing, far more than just that I’ve discussed here (see previous blog articles). The somewhat unfortunate part was the way in which the E10001 test series came to an end. On test A2J021, we had a disconnection between the intent for test and the detailed planning that led to the actual hardware configuration we ran for the test. That disconnection led to an ill-fated situation. Let me explain…

The J-2X gas generator has ports into which solid propellant igniters are installed. These igniters are like really high-powered Estes® rocket motors that light off when supplied with a high-energy electrical pulse. The flame from the igniter lights the fire of the hydrogen-oxygen mixture during the engine start sequence. It’s essentially the kindling for the fire of mainstage operation. The igniters perform this function at a very specific time during this sequence. If you try to light the fire too early, then you may not have enough propellant available in a combustible mixture so you get a sputtering fire. If you try to light too late, then you may have too much propellant built up such that rather than getting a good fire, you get an explosion instead. But here’s a key fact: You have to plug them in or they don’t work.

Have you ever stuck bread in the toaster, pushed down the plunger, gone off to make the coffee, and come back only to find that your darn toaster is broken? You curse a little because you’re already late for work and this is the last darn thing you need. You would think that somebody somewhere could make a toaster that lasts more than six months or a year or whatever. For goodness sake! We put a man on the moon and yet we can’t … oh, wait … um … ooops, it’s not plugged in. My bad.

In a nutshell, that’s what happened on test A2J021. The electronic ignition system sent the necessary pulse, but because of the uniqueness of our testing configuration as opposed to our flight configuration the wires carrying the pulse weren’t hooked up to the little solid propellant igniters in the gas generator. In the picture below you can see the external indication that something was not entirely good immediately after the test. The internal damage was more extensive to both the gas generator and the fuel turbopump turbine.

Many years ago, I met an elderly engineer who was still on the job well into his 80’s because he loved his work. His entire career had been dedicated to testing. He’d actually been there, out in the desert, in the 1940’s testing our very earliest rockets as part of the Hermes Project. One day, they had a mini disaster on the launch pad. He told me that the rocket basically just blew up where it sat. Boom and then a mess. And, it was his job to assemble the test report. Being a conscientious, ambitious, young engineer, he recorded the facts and offered a narrative abstract and extensive, annotated introduction that categorized the test as, well, a failure. Not long after submitting his report, one of the senior German engineers in the camp came into his office, put the test report down on the desk, and said that the tone of the report was entirely wrong. He said, “Every test report should begin with: ‘This test was a success because…'” The purpose of testing is to gather data and learn. If you learn something, then your test was, by definition, a success on some level. I’ve tried very hard to remember this very important bit of wisdom.

So, A2J021 was a success because we learned that we had some deficiencies in our pre-test checkout procedures. It was a success because it was an extraordinary stress test on the gas generator system. No, it didn’t recover and function properly, but neither did the engine come apart. While that might seem like a minor detail, when you’re hundred miles from the surface of the earth, you would much rather have a situation where an abort is possible than a failure that could result in collateral vehicle damage and make safe abort impossible. We have a stout design. Good. Also, this test failure was due to a unique ground test configuration. In flight, it’s not really plausible just because we would never fly in this configuration.

So, E10001 completed its test program with a bang. Kinda, sorta literally. But it was nearly the end of its design life anyway, so we didn’t lose too many test opportunities, and, as I said, even with test A2J021 the way it happened we learned a great deal. Overall, the E10001 test series was an outrageous success. Rocketdyne, the J-2X contractor, ought to be darn proud and so should the outstanding assembly and test crews at the NASA Stennis Space Center and our data analysts here at the NASA Marshall Space Flight Center. Bravo guys! Go J-2X!

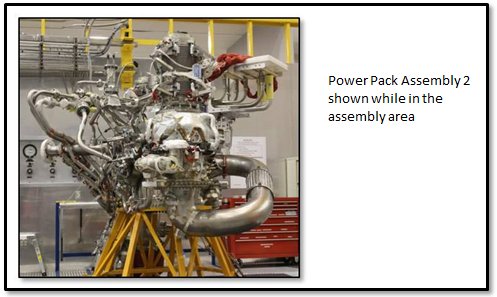

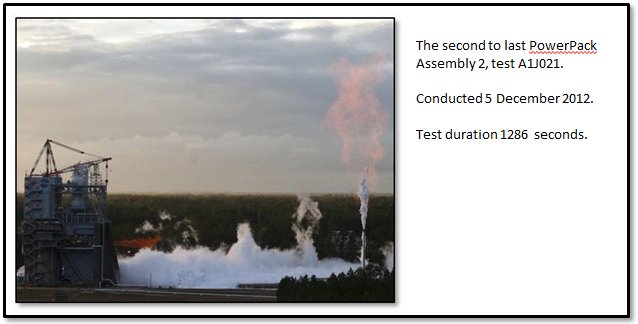

Power-Pack Assembly 2 (PPA-2) Testing is Complete!

Over ten months and across the span of thirteen tests, nearly 6,200 seconds of engine run time was accumulated and recorded on the J-2X Power Pack Assembly 2. That’s over 100 minutes of hot fire. Three of the tests were over 20 minutes long (plus one that clocked in at 19 minutes) and these represent the longest tests ever conducted at the NASA Stennis Space Center A-complex. But more than just length, it was the extraordinary complexity of the test profiles that truly sets the PPA-2 testing apart.

Because PPA-2 was not a full engine with the constraints imposed by the need to feed a stable main combustion chamber, and because we used electro-mechanical actuators on the engine-side valves and hydraulic actuators on the facility side valves, we could push the PPA-2 turbomachinery across broad ranges of operating conditions. These ranges represented extremes in boundary conditions and extremes in engine conditions and performance. On several occasions we intentionally searched out conditions that would result in a test cut just so that we could better understand our margins. As the saying goes: It’s only when you go too far do you truly learn just how far you can go. We successfully (and safely) applied that adage several times. In short, we gathered enough information to keep the turbomachinery and rotordynamics folks blissfully buried in data for months and months to come.

On an interesting and instructive side note, the PPA-2 testing also showed us that we needed to redesign a seal internal to the hydrogen turbopump. In the oxygen turbopump, you have an actively purged seal between the turbine side and the pump side. After all, during operation you have hydrogen-rich hot gas pushing through the turbine side and liquid oxygen going through the pump side. You obviously don’t want them to mix or the result could be catastrophic. That’s why we have a purged seal. But for the hydrogen turbopump you don’t have such an issue. During operation, at worst should the two sides mix you could get some leakage of hydrogen from the pump side into the turbine side that is already hydrogen rich. In order to maintain machine efficiency, you don’t want too much leakage, but a little is not catastrophic (and can be used constructively to cool the bearings). What could be dangerous at the vehicle level, however, is if you have too much hydrogen floating around prior to liftoff. This is especially true for an upper-stage engine like J-2X that’s typically sitting within an enclosed space until stage separation during the mission. You could have the engine sitting on the pad for hours chilling down and filling the cryogenic systems and you don’t want gobs and gobs of hydrogen leaking through the turbopump since any leakage ends up within the closed vehicle compartment housing the engine. That’s just asking for an explosion and a bad day.

To avoid this, within the J-2X hydrogen turbopump we have what is called a lift-off seal. And, as the name applies, it’s a seal that actively lifts off when we’re ready to run the engine. When the engine is just sitting there chilling down, not running, with liquid hydrogen filling the pump end of the hydrogen turbopump, the seal is, well, sealed. Then, when we’re ready to go, it unseals and allows the turbopump to operate nominally.

During the PPA-2 test series we found that we formed a small material failure within the actuation pieces for our lift-off seal. Then, upon analysis of the test data and a reassessment of the design, we figured out what was most likely the cause and Rocketdyne proposed a redesign to mitigate the issue. Again, going back to that important piece of wisdom: This testing was a success because, in part, we learned that we needed a slight redesign of the lift-off seal. That’s the whole purpose of development testing! Everything always looks great when it’s just in blueprints. It’s not until you hit the test stand do you truly learn what’s good and what need to be reconsidered. In the end, this sort of rigor and perseverance is what gives you a final product that you feel good about putting in a vehicle carrying humans in space. And that, truly, is what it’s all about.

As with E10001, the PPA-2 test series was simply an outrageous success. Rocketdyne should be proud and so should the outstanding assembly and test crews at the NASA Stennis Space Center and the data analysts at the NASA Marshall Space Flight Center. Bravo guys! Go J-2X!

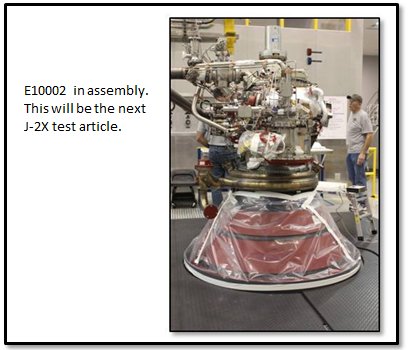

Engine #2 (E10002) Assembly is Underway

Our next star on the horizon is J-2X development Engine 10002. It is being assembled right now, as I’m typing this article. It is slated for assembly completion in January 2013 and it will be making lots of noise and very hot steam in the test stand soon after that. While our current plans are to first test E10002 in test stand A2, we will later be moving it to test stand A1. This, then, will be the first engine then to see both test stands. The more important reason for the A1 testing, however, is because that will give us the opportunity to hook up some big hydraulic actuators and gimbal the engine, i.e., make it rock and tilt as though it were being used to steer a vehicle. Now that will be some exciting video to post to the blog! I can’t wait.

Happy New Year!

So, this has been my “it’s been awhile” letter. Hopefully this will bring everyone up to speed with where we stand with J-2X development. In my next article, I will share with you some of what’s been keeping me from my J-2X article writing over the last several months. And, hopefully, it won’t be several months in the making. So, farewell for now and Happy New Year! On to 2013 and another great year full of J-2X successes. Go J-2X!

Thanks for another informative, interesting and easy to read report on the J-2X development. Already looking forward to the next installment.

My questions: when will J-2X get to fly on the new A-3 test pad at altitude? Will this testing use a flight qualified ignitor? And finally, will the engine be able to restart in flight for more complex orbital manuevers?

Sincerely,

Lin Farmer, old steam engineer

Congratullations for these successful series of test.

Should be of interest to get more details on the Nozzle Extension behavior and potential of the technology for a full scale one.

Can you tell us more?

As always, its a big pleasure to read this posts. The complexity of bulding and running a rocket engine is incredibly. Please keep up the great work, i would love to work along people like you, trying my best to get humanity off this rock and into the stars. Thanks for all the great work.

@guest:

Well, I can tell you that thus far the nozzle extension emissivity coating has held up well under hot-fire conditions. We’d gone through an extensive test program a couple of years ago trying to find the right coating. Not only did we need to achieve certain emissivity properties to enhance radiation heat transfer properties, but we also had to find a material that could withstand the extraordinary environments of the discharge end of a rocket engine.

We coated test panels and stuck them into a test facility that was originally developed to test the aerothermal and aerodynamic effects of the Space Shuttle ascent environment on the foam insulation covering the external tank. This testing at the panel level allowed us to cull the field of contenders and eventually make a choice, but because the test conditions couldn’t entirely match what we expected to see on the engine itself, it was not until this test series that learned for sure that our coating material (and application process) was good.

In addition to radiation cooling, the nozzle extension is also cooled by injection of turbine exhaust gases around the perimeter where the nozzle extension attaches to the regeneratively cooled nozzle. One of the analytical difficulties we’ve had is determining the effectiveness of this method of cooling given the extreme local environment we had. We have analytical models but, we felt, probably not enough empirical data upon which to anchor these models.

These two examples illustrate one of the chief difficulties that we always face with rocket engines. It’s tough to simulate rocket engine conditions without building and testing, well, a rocket engine.

@Lin Farmer:

As of right now, we do not have plans to test J-2X on test stand A-3. But that’s just right now based upon our current focus and priorities.

When we began J-2X development, our objective was to support the Ares I vehicle and that vehicle required the full-length nozzle extension. That’s largely why we built A-3. Now, with J-2X part of the Space Launch System (SLS) Program, the baseline is to fly with just the “stub” nozzle extension. With that as the baseline, we don’t need A-3 testing in the near term. However, should the higher performance version of J-2X become necessary to support SLS or any other use, NASA Stennis Space Center has responsibly developed A-3 to a point where it can be completed and activated when we need it in the future.

The igniters that we’re using now, both the electrical igniters in the main chamber and the pyrotechnic igniters in the gas generator, will be the flight qualified configuration once we complete overall qualification of the engine. This issue that we had on A2J021 was more a matter of the wiring configuration rather than any issue with the igniters themselves.

The J-2X is designed to restart once in space, just like its namesake predecessor, J-2. Thus, J-2X can help with the ascent phase of the launch vehicle and then, after that, supply the necessary oomph to push out of earth orbit and head out to the Moon or Mars or wherever else we might be headed. Again, this is the same kind of mission duty that J-2 had as part of the Saturn V launch vehicle during the Apollo Program era.

Glad you are still writing this blog. BTW, at the time of the Marvelettes, the Estes® model rocket motors you wrote about could be obtained by mail order. Not sure my parents were happy about that.

What was the date of the A2J021 test that had the issue – the posting on the SSC site don’t seen to mention the issue you listed in your blog?

Is there a listing somewhere on the J-2X website that lists all of the J-2X firings (full and powerpack)? It would be really nice to see such a list to cross list dates/engine/test number/duration/etc.

great blog!

@Tom: Below is the test history to date showing Engine 10001 and PowerPack Assembly 2.

Engine 10001 Testing

Test # — Date — Duration

A2J001 — 7/7/2011 — 1.1

A2J002 — 7/14/2011 — 1.9

A2J003 — 7/26/2011 — 3.7

A2J004 — 8/5/2011 — 7

A2J005 — 8/17/2011 — 32

A2J006 — 9/29/2011 — 40

A2J007 — 10/25/2011 — 140

A2J008 — 11/9/2011 — 500

A2J009 — 12/1/2011 — 80

A2J010 — 12/14/2011 — 235

A2J011 — 4/26/2012 — 3

A2J012 — 5/16/2012 — 7

A2J013 — 5/25/2012 — 40

A2J014 — 6/13/2012 — 260

A2J015 — 7/13/2012 — 550

A2J016 — 7/27/2012 — 3.6

A2J017 — 8/8/2012 — 60

A2J018 — 8/17/2012 — 250

A2J019 — 9/7/2012 — 250

A2J020 — 9/14/2012 — 250

A2J021 — 9/25/2012 — 3.5

PowerPack 2 Assembly Testing

Test # — Date — Duration

A1J010 — 2/15/2012 — 1.9

A1J011– 3/13/2012 — 2.2

A1J012 — 3/18/2012 — 3.7

A1J013 — 4/5/2012 — 7.2

A1J014 — 4/13/2012 — 13.6

A1J015 — 5/10/2012 — 340

A1J016 — 5/24/2012 — 32

A1J017 — 6/8/2012 — 1150

A1J018 — 7/24/2012 — 1350

A1J019 — 8/16/2012 — 1261

A1J020 — 11/8/2012 — 278

A1J021 — 12/5/2012 — 1286

A1J022 — 12/13/2012 — 451

Hi

Thank you for your great and informative blog.

Can you give a beginner like me an idea of what you are testing for and where you have got to with it? What have been your major successes so far? Is it all about how long you fire the engine for, testing for turning it off and on in the conditions in space?

Thanks!

Hannah

I haven’t seen much activity here recently, so I thought I’d post something. I’m sure you are very busy with the J2-X, and I’d much prefer you working on that, so that it is successful and safe!

Anyway, as with most of my posts, it is not directly related to the J2-X. I just saw a recent story about a couple of original F-1 rocket engines being pulled up from the bottom of the Atlantic ocean to be restored.

So, my question is, for an engineer who works on rocket engines, does this type of thing fascinate you and your peers? Do you plan on going to see these engines? I also read an article about how the SLS program may utilize features of the F-1 in its work to design an even more powerful rocket engine.

The work you all do there is amazing! Thank you all for your hard work in making some of the most amazing pieces of machinery we have ever known!!

Is this blog dead or will this be updated soon since a lot of progress has occurred since this last post was added on 08 January 2013. A new update bringing the public up to date on the latest progress over the last and current quarters of the fiscal year would be nice for a change.

Hi RH117 –

We appreciate your interest in this blog because there are a number of exciting things happening. Bill is currently in the process of completing his next post that will talk about the expansion of the office from strictly J-2X to liquid rocket engines in general and RS-25 in specific. Stay tuned!

Thanks

Kris, so will this blog now also cover upcoming liquid rocket engine testing (PWR F-1, F-1B and Aerojet AJ-1-E6) by private industry across several NASA centers for NASA’s open competition for the SLS advanced booster contract. Also will this blog now also cover SLS core stage testing at NASA-SSC’s B Test Complexes B-2 Test Stand and if yes, will this blog cover the renovations/major modifications/upgrades currently underway to the B-2 side of the B Test Complex. Also is the B-1 side of the B Test Complex going to be modernized too? In addition to my above questions, what is the current status of A Test Complexes A-3 Test Stand as the links on NASA-SSC’s website for A-3 and every other test stand are now broken when the front page of the site was last updated.

I hope to be working in the field sometime in the next few years.

RH117: Hold on. A couple of things…

First, this blog will be expanded to talk about specific engines under the auspices of the SLS Program. And, it will continue to contain general engine-related stuff as interesting topics come up.

We may have the opportunity to discuss other engines out there, but if NASA is not directly involved, there are often (completely reasonable and understandable) barriers up to protect proprietary data or business plans or such. We’ll just have to see what’s possible.

In terms of what’s going on over on NASA SSC test stand B-2, those are preparations for SLS core stage testing. Now THAT will be some exciting stuff. We’ll be coving the engines perspective here but the stages perspective will be covered by, well, the stages folks.

And that leads me to a minor announcement that the SLS Program plans to expand this notion of blogging beyond J-2X and beyond liquid engines to the vehicle and program as a whole. So, coming your way at some point this summer, more subjects, more authors, more articles.

So far as coming to work in the field soon, c’mon along for the ride. Finish up your studies and let’s get to work. There is plenty of good stuff to do.