This article is the second part of the story focused on how we start rocket engines. In the last article, we discussed the matter of delivering propellants – oxidizer and fuel – into the combustion zone. In this article, we will discuss how these propellants become fire and smoke (…or steam). Of course, the musical reference for which you’re waiting ought to be based on the title of this article and the song by the Doors. Right? Well, with all due respect to The Lizard King, I would prefer to reference here the immortal writings of The Boss:

I will now be so bold as to translate Mr. Springsteen’s words into functional advice for rocket engines. Sitting around and crying or worrying about the world are both passive, energy-draining activities. The only way to start a fire is to add energy, e.g., a spark, to the situation. He’s absolutely right. And I would just bet that you never knew that The Boss was a rocket scientist.

In an article about combustion instabilities many months ago, I used the image below to illustrate a situation of limited stability. The ball sitting on top of the hill will sit there forever unless or until something disturbs it. Give it a little bump, i.e., an insertion of energy, and the whole scenario rapidly changes with the ball speeding down the hill.

This is also how I think about the process of ignition for typical, non-hypergolic (see previous article) propellants. You can have fuel and oxidizer sitting around, intermixing, but until it gets that bump of an insertion of energy, there is no combustion. No combustion; no high-energy gas production. No high-energy gases; no propulsion.

Let’s start from the other end. For a moment, think about a fire in your fireplace. Once you’ve got a good fire up and going as in the picture below, you don’t have to re-start the fire each time that you add a log. The existing fire sustains itself so that the energy produced by the combustion in one moment is sufficient to continue the fire into the next moment using additional fuel (the wood) and oxidizer (from the air).

This is generally the case for rocket propellants as well. Once the fire is lit (i.e., once the ball is rolling downhill), the process is self-sustaining. So, the whole issue about making a fire really does come down to the start of the process.

How many different ways can you start a fire? One way is to use another fire. Think about the folks running around the countryside with the Olympic torch before the games. They use that torch to light another torch to light another torch, and on and on, all of the way until they light the big torch in the stadium. Another way to start a fire is to use heat. That, effectively, is how I lit a cigar the other evening. I used friction to generate heat to ignite a match. Then, holding the match like an Olympic torch, I used that fire to light the fuel of the cigar tobacco. This model of a cascading series of larger and larger fires is used over and over in different forms. Thus, when we talk about starting a fire, we often have to discuss not only the small initial energy bump, but then also the chain of events leading to the complete, steady state process.

So, first we have the initiation, or as The Boss said, “the spark.” Off the top of my head, I can think of four ways that we’ve practically implemented on rocket engine systems to provide that initial energy boost and one other way that, to date, remains somewhat experimental. There may be others, but these are the ones that are most obvious and frequently used in different forms.

The first method is exactly what The Boss calls for, an electrical spark. In most cases when lighting liquid propellants directly, the components on rocket engines used to make electrical sparks are not a whole lot different than higher-energy, more robust, and more reliable versions of the spark plugs that you’ve got in your automobile. They use a high-voltage electrical circuit to make a spark jump across a gap thereby exposing whatever is around that gap, namely vaporized propellants, to ionizing electrical energy.

The second method also uses electrical energy but in this case rather than making a spark, you use it to make heat. Think about an incandescent light bulb (i.e., the bulbs rapidly becoming old fashioned these days). The intent of the wire filament is to produce light. And it does. But is also produces heat. What if you apply that heat directly to a combustible mixture? Depending upon the mixture, that’s all you need. I’ll explain more below when we talk about the cascade.

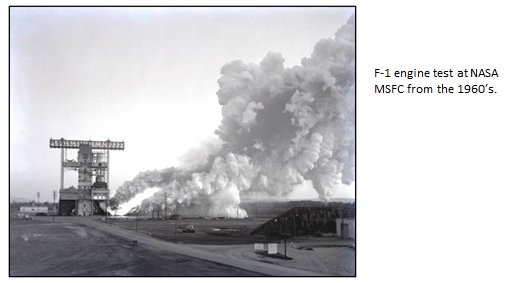

These first two methods rely on electrical energy and that’s always convenient since wires are easy to run. While it’s true that the ultimate power source can be heavy for the vehicle (batteries for example), the rest of the system is relatively light and easy. The third method for providing that initial energy bump is not quite so clean. Rather than relying on transferring electrical energy into a chemical reaction, it uses a transfer of energy from one chemical reaction to kick off another chemical reaction. In the previous article we discussed hypergolic propellants. These are propellants that combust spontaneously when they come into contact with each other. They don’t need any energy boost to start reacting. Well, what if you had a fluid that did that when it came into contact with your primary fuel or primary oxidizer? You could squirt in some of this spontaneously combusting stuff, light off a small bit of your fuel or oxidizer, and then the energy for that small fire could light off the rest of the propellants. This is a common means for starting kerosene (also called RP-1) engines. The massive F-1 engine used as part of the Saturn V vehicle was lit by a hypergolic ignition system for the main combustion chamber. The most common hypergols for this purpose are triethylborane (a.k.a., triethylboron), triethylaluminum, or some mixture of the two.

The fourth and last method that I can think of for supplying that initial energy bump again starts with electricity, but instead of generating a localized spark or heat, you transform the electrical energy into a laser. I will not even begin to pretend that I know much about lasers other than the fact that they can provide a very focused, directed beam of energy, photon energy in this case, to exactly where you want to put it. You can use that energy to make heat for ignition or – and now I’m way beyond my knowledge base – you can tune the wavelength to excite the propellant molecules directly. I have a friend in Germany who has experimented with using lasers for rocket engine ignition. Thus far, I know of no fielded rocket systems where this ignition method is used (although I’ve been told that the Russians have demonstrated it on a full-scale engine), but it offers some very interesting possibilities.

So, we’re done, right? After all, you’ve got your spark (or some other energy boost) so you’re lit and ready to go. Well, not always. For the most convenient ignition source, specifically the electrically-flavored ones, our bump in energy, our spark or heat, is usually very localized. Rocket propellants are usually highly energetic and that’s why they’re rocket propellants. But that also means that you have to light the fire well. I struggle with how to explain this in a positive sense, so I’ll explain it in the negative, i.e., tell you what you do not what to do.

In your combustion zone, you do not want to ignite just one small space, i.e., one corner, and let the fire spread unevenly. A fire on one side of a combustion zone but not the other could allow unburned propellants to momentarily “pool” in the one region. This could lead to detonation and/or conflagration pressure waves bouncing around your chamber until everything evens out. That can be extremely dangerous to the point of tearing apart the engine. Or maybe, because of these pooled, unburnt propellants, you get mixture ratios that cause hot streaks. Most practical combustion chambers are not built to accommodate stoichiometric or oxidizer-rich combustion (unless it is specifically an ox-rich preburner where it is should be very ox-rich to avoid this same issue). A localized phenomenon of a slight ox-rich ignition could burn a hole right through a combustion chamber wall. Or, if you’re talking about a gas generator or a preburner, you could get hot streaks that damage turbine components. I have seen the kind of damage that can be done in a turbine due to ox-rich hot streaks for just fractions of a second.

Ideally, what you want is for your propellants to arrive and, blammo, everything it lit. That “blammo” can be difficult to achieve with a localized energy into like a spark or a small electrical heat source, especially for larger engines. To overcome this issue, we turn back to the simple analogy of the fireplace. There, we go from the localized effect of the match, to perhaps a ball or two of crumpled newspaper, to shavings or kindling, to larger sticks, to eventually the logs. So there is a cascade of events from small and localized to large and generalized. I will give you two examples of how we apply this concept in rocket engines.

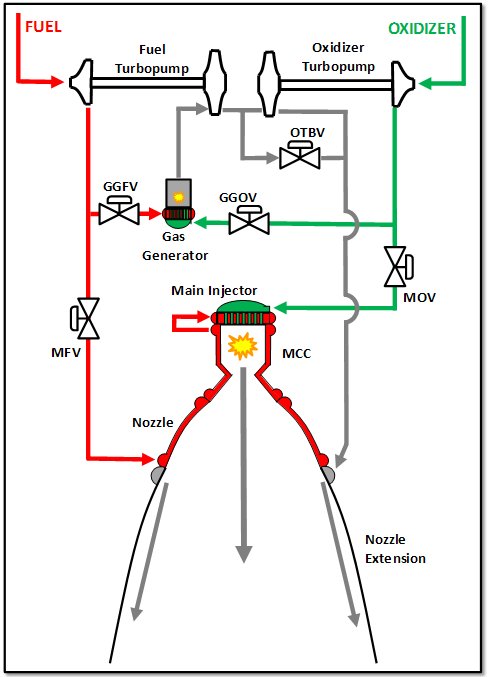

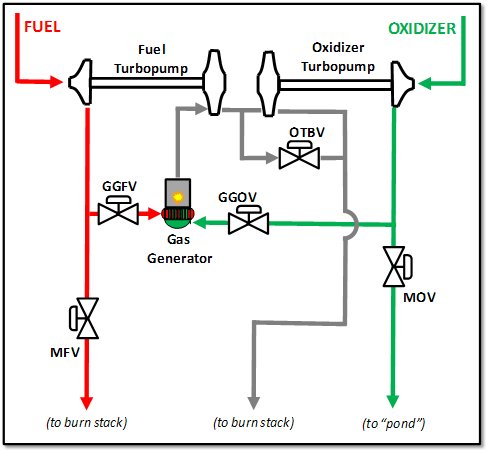

The J-2X gas generator has a pyrotechnic ignition system. It’s quite easy to tell people that we ignite the GG with little, solid propellant charges. Okay, but is that the whole story? No, it’s not. The solid propellant charge (think about little Estes® rocket motors) is just the fire-lighting-the-fire end of the process.

It all starts with electrical current running through an igniter wire. The electrical resistance of the igniter wire causes heat as the current passes through. That heat is enough energy to push what’s called the “pryogen” into ignition. You can think of the pryogen as being like the stuff on the head of a match. Other flammable substances are often used but the idea is still the same. That little fire in the initiator ignites the solid propellant and the solid propellant then shoots hot gases into the GG during the engine start sequence to ignite the hydrogen and oxygen just as they arrive. Pyrotechnic igniters like this are highly reliable. If that electrical current arrives, everything beyond that is pure chemical chain reaction that produces a powerful blast of ignition energy. On the negative side, such an igniter can only be used once. I guess that you could inspect and refurbish elements of the piece, but considering the trauma of the process it experiences, it is easier and cheaper to simply replace the whole thing.

Another example of the concept of using an ignition cascade can be found on the J-2X in the form of the torch igniter used for the main injector. Here’s an interesting little piece of history (as it’s been told to me). The J-2 engine, back in the 1960’s was a pioneering effort. While the RL10 was already flying, the use of hydrogen as a propellant was still something relatively novel. For the J-2 main injector they developed a torch igniter system. That system was later adopted and modified slightly for use as the ignition system for the Space Shuttle Main Engine main injector and both preburner injectors. When we came to the development of J-2X, we started with our many years of successful experience with the SSME torch ignition system, made some modifications and, through a dedicated test program at the igniter level, effectively revalidated and expanded upon the pioneering efforts of the 1960’s. It’s good to be part of another small step in that long and successful history.

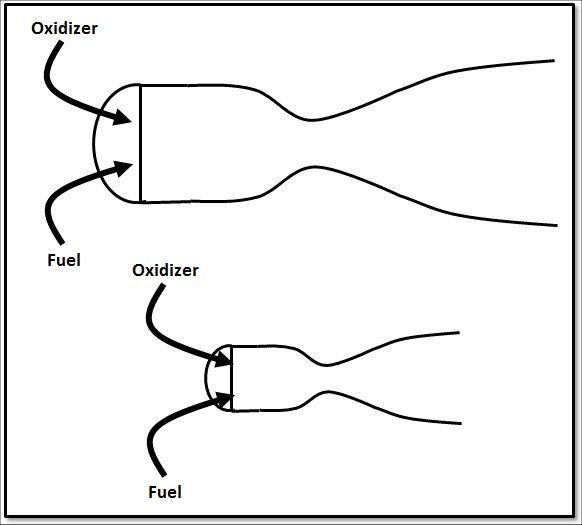

The torch igniter concept starts with an electrical spark from what really looks like your ordinary automobile spark plug. But such a spark is very small, very localized. So what you do is swirl into that localized area just a little hydrogen and oxygen. This is the kindling. The electrical potential across the gap of the spark plug causes the gasified propellants to ionize and become very hot, hot enough to start to spread the fire and, from that, thereby creating a flame front. That flame is then directed into the combustion zone just as the rest of the propellants are reaching the injector. The whole igniter system is effectively a torch ejecting a flame into the combustion zone. In the J-2X (and in the SSME and in the J-2), the torch is right in the center of the injector face.

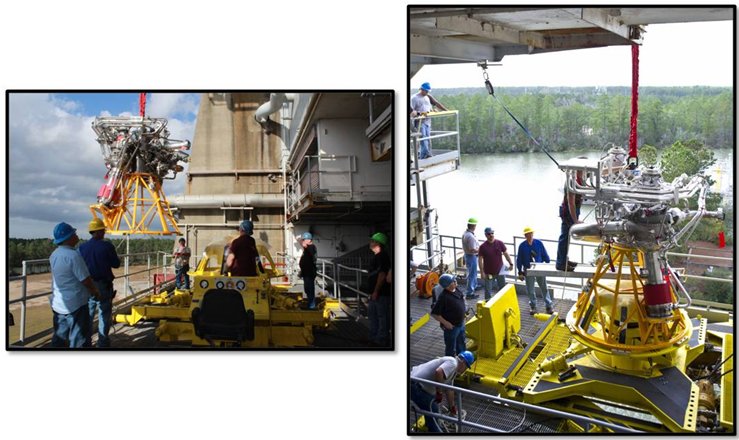

Okay, so there you have it, in two articles, how to get a liquid rocket engine up and going. First, you have to get the propellants moving to the right places and, second, once they’re there, you’ve got to light the fire. For large rocket engines, the whole process from the receipt of the start command from the vehicle until the engine is functioning at full power level takes anywhere from about three to six seconds. During that time, pumps have to start spinning, valves have to open, propellants have to reach their destinations in the correct proportions, and the ignition source has to try to light the fire not too early and not too late. It really is quite an orchestration of events across a brief period of time. And the more complex the engine, the more difficult it is to get the orchestration right.

Looking into the database for SSME history, the very first test was conducted on 10 May 1975 with development engine #1 on test stand A1. It was not until the forty-second test of the test series, nearly ten months later, that they eclipsed five seconds of firing duration and reached true mainstage operation. So, it was not easy making that orchestration work. Over the years, I’ve had the opportunity to meet and work with a handful of the folks who were there figuring out how to make the SSME work. They were all very impressive engineers and thank goodness since we are still benefitting from their efforts. And with that final historical note, we end this article with some more words of wisdom from The Boss:

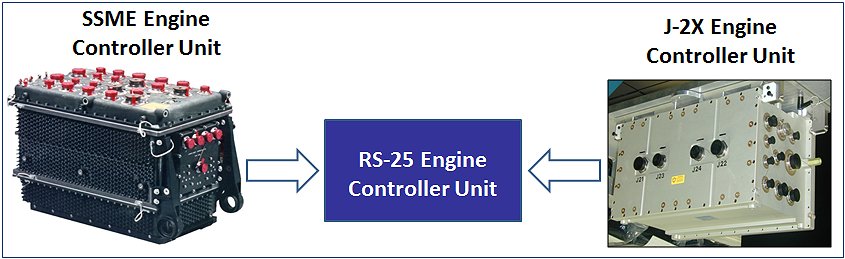

The name “RS-25” is, as I’ve mentioned in past articles, the generic name for the engine that everyone has known for years as the “SSME,” i.e., the Space Shuttle Main Engine. There is much to talk about the RS-25. Lots and lots of stuff. More stuff that I could possibly fit into a single article. Here are just some of the RS-25 topics that we’ll have to defer to future articles:

The name “RS-25” is, as I’ve mentioned in past articles, the generic name for the engine that everyone has known for years as the “SSME,” i.e., the Space Shuttle Main Engine. There is much to talk about the RS-25. Lots and lots of stuff. More stuff that I could possibly fit into a single article. Here are just some of the RS-25 topics that we’ll have to defer to future articles:

have guessed, this is something that I wondered about many years ago as a pre-engineering spud. They seemed to be an awfully silly thing to build when you could just turn on the faucet and have water spurt out whenever you want. Ah, the wonderful simplicity of childhood logic: Things work just because they do and every day is Saturday.

have guessed, this is something that I wondered about many years ago as a pre-engineering spud. They seemed to be an awfully silly thing to build when you could just turn on the faucet and have water spurt out whenever you want. Ah, the wonderful simplicity of childhood logic: Things work just because they do and every day is Saturday.