As I was driving to work this morning, I came up over a rise and saw suddenly appear in my windshield, over towards the left on the other side of the road, a police cruiser with a radar gun mounted in the window. Even before I could think about it, the pressure of my right foot on the accelerator lessened. I then instinctively looked at the speedometer and found that I was traveling 48 miles per hour on a road for which the speed limit is 45 mph. Thankfully, the officer apparently forgave me the 3 mph violation and continued to wait where he was for a better opportunity to serve and protect the community.

First, let’s get familiar with a couple of terms –

Open-loop: We typically refer to something as open-loop when we have instrumentation that measures conditions in the engine but the engine itself does not respond to those measurements.

Closed-loop: We typically refer to something as closed-loop when we have instrumentation that measures conditions in the engine and then, potentially, the engine takes action based upon those measurements.

It is based upon those definitions that I would call my response to seeing the cruiser closed-loop since I responded and did something with the data. Another example would be the more modern systems that are used to monitor and control automobile systems. It used to be that you had a temperature measurement stuck in the coolant loop. You could watch the temperature rise, but until the system went kaput and boiled over leaving you stranded alongside the road, there was no active, closed-loop control. Nowadays, if the computer in my pickup truck sees that the engine temperature is too high, it will take action to try and protect itself. For example, it will inhibit the use of the air conditioning system since that represents an additional power requirement on the engine.

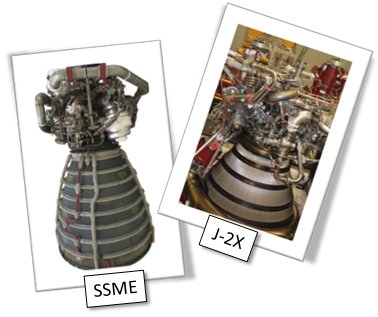

One thing that we control is power level. On the Space Shuttle Main Engine (SSME), power level is controlled in a closed-loop manner. This means that the main combustion chamber pressure is measured as an indication of thrust level and in response to that measurement a valve is opened or closed to increase or decrease the engine power level. On the J-2X, power level is controlled in an open-loop manner. This means that we measure the main combustion chamber pressure but we don’t have any feedback loop where we control a valve to ensure that we’re on target. Instead, should we happen to be off on power level, we have to physically change an orifice in the engine between tests. The “feedback loop” is data analysis and a guy with a wrench. Which approach you choose to take are dependent upon your requirements of performance and affordability.

Another thing that we control on a rocket engine is the mixture ratio (i.e., the ratio of oxidizer to fuel). Given that on a rocket you are carrying both your oxidizer and fuel with you in the vehicle, you certainly want to make sure that you consume your propellants in the correct ratio to get the most uumph out of them. Again, on SSME we control mixture ratio in a closed loop manner. There is actually a small flowmeter on the SSME and, using the data from that flowmeter (and some associated calculations), we move a valve on the engine to dial in the correct mixture ratio. It’s a pretty nifty system. Also again, on the J-2X, we have an open-loop system for mixture ratio just like we have for power level. We test the engine, look at the results, and, if necessary, make a physical change to the engine in the form of an orifice.

Because of these two areas, power level and mixture ratio, SSME is usually referred to as a “closed-loop engine” and J-2X is usually referred to as an “open-loop engine.” Now, this terminology is not entirely correct since there are some closed feedback loops within the J-2X control system pertaining to engine health and status diagnostics, but we all know how enduring shorthand designations can be. Also, engines don’t have to be one or the other. They can be half-and-half. The engine used on the Delta IV vehicle, the RS-68, sort of falls in this category.

How you choose to design your engine control system is driven by your requirements. Put real simply: The SSME is all fancy-schmancy because it had extremely tight power level and mixture ratio precision requirements and because it was a reusable engine. The J-2X is intentionally more simplistic because it has looser precision requirements and because it is expendable (and throwing away orifices is a whole lot cheaper than throwing away valves if your requirements will let you get away with it). Requirements drive design.

Note that I will save the fun topic of engine diagnostics — and the potential for long philosophical meanderings within that realm — for future posting.

Let’s end this posting with a fun little exercise. Above is a simplified schematic of a gas-generator cycle engine kind of like a J-2X. I have shown in the schematic two orifices #1 and #2 (highlighted in yellow). With those two orifices, we can calibrate the engine.

Scenario: Power level too low, i.e., measured main combustion chamber pressure too low.

· Solution: Increase the size of orifice #1.

· Explanation: By increasing the size of orifice #1, I will deliver more oxidizer to the gas generator. This will deliver more power to both turbines thereby increasing how much propellant gets pumped into the engine. More propellants pumped in equals more thrust and greater overall power level.

Scenario: Power level too high, i.e., measured main combustion chamber pressure too high.

· Solution: Decrease the size of orifice #1.

· Explanation: The exact opposite of the previous scenario.

Scenario: Mixture ratio too low, i.e., the flow of oxidizer is too low in proportion to the flow of fuel, as measured by the test facility.

· Solution: Decrease the size of orifice #2 and decrease size of orifice #1.

· Explanation: By decreasing the size of orifice #2, I decrease the amount of flow that is diverted around the oxidizer turbopump turbine. I therefore increase the flow through the turbine thereby increasing pumping power of the oxidizer side. So I increase oxidizer flow to the engine. However, by increasing oxidizer flow to the engine and doing nothing else, I’ve probably messed up my overall engine power level so I’ve got to back down a little bit by decreasing the size of orifice #1.

Scenario: Mixture ratio too high, i.e., the flow of oxidizer is too high in proportion to the flow of fuel, as measured by the test facility.

· Solution: Increase the size of orifice #2 and increase size of orifice #1.

· Explanation: The opposite of the rationale for the scenario immediately above.

See, being a rocket scientist isn’t that difficult, really. Now you too can calibrate an open-loop rocket engine.

P.S., I read in the paper this morning that NASCAR racer Kyle Busch had his civilian driver’s license revoked for 45 days for doing 128 mph in a 45 mph zone. Well, at least I wasn’t going that fast when I came over the rise this morning and saw the police cruiser. Then again, I wasn’t driving a $400,000 Lexus LFA sports car like Mr. Busch was…