There have been recent reports containing a leaked preliminary internal Air Force assessment document regarding potential abort scenarios for the Ares I rocket and the effect on an Orion crew exploration vehicle. The assessment, as preliminary, addressed a certain class of abort scenarios. This class of aborts involves destruction of the first stage because of either a case over-pressure or because of a range safety initiated destruct command. The majority of aborts do not fall into this category because of the abort criteria and flight rules the program is implementing. The analysis is not an official Air Force position, but a starting point for working specific issues associated with the complexities of aborts. An ongoing exchange of information and analysis is part of the formal process for the 45th Space Wing to evaluate a new vehicle’s request to use the Eastern Range and establish an operations agreement. NASA and the Air Force work together through routine technical interchange meetings to share data and analysis on launch vehicles and payloads. This is typical of how the two organizations have worked together in the past to evaluate Apollo, space shuttle, and nuclear payload missions such as New Horizons as they were in development. A joint team, comprised of experts from both NASA and the Air Force, meets routinely to collaborate on issues related to range safety, and works to provide answers to all outstanding questions and concerns. The program will continue to work closely with the 45th Space Wing to mature the analyses as the development of the vehicle continues, with the top priority being the ability to protect the crew and public. Ares/Orion were conceived and are being designed as the safest launch vehicles in history. The findings in this preliminary Air Force analysis have provided insight into the abort environment, and each issue and concern will be answered as NASA shares more in-depth studies and analysis with the Air Force and continues to refine its models and data. Constellation is a developing program and NASA will continue to work with the Air Force as the two agencies collaborate to assure both crew and public safety.

Tag: Safety

All eyes on LRO

Constellation has its eyes on the Lunar Reconnaissance Orbiter and is anticipating some great images. The spacecraft entered lunar orbit on the morning of June 23 and after that orbit is refined engineers will power up and calibrate LRO’s instruments. In a couple months, LRO will begin mapping the lunar surface to find future landing sites and searching for resources that would make possible a permanent human presence on the moon.

While the Apollo missions demonstrated that that it was possible to send humans to the moon, they did so for very short times – only three days, and at great risks. The LRO mission is paving the way for extended human habitation on the lunar surface and striving to reduce the risks to the astronauts travelling there.

LRO’s very high resolution cameras and laser altimeter will examine more than 50 potential landing and outpost sites on the lunar surface in enough detail to resolve an object the size of a beach ball. This will provide information to engineers currently designing the Altair lunar lander and allow them to build safe and effective landing systems, and will give mission planners the information they need to select safe landing sites.

Plus, the logistics resupply of a lunar outpost will be a challenge far exceeding that of the International Space Station. It will be necessary for lunar astronauts to learn to “live off the land” by utilizing the resources available on the moon. These may include water in permanently shadowed regions of the lunar poles, which could be invaluable for both consumables for the astronauts and propellant for their spacecraft. LRO instruments will map these regions of shadow and determine whether and where these resources are located. In addition, LRO will map the resources of the entire moon’s surface looking for deposits of other valuable resources, such as oxygen, locked in the lunar soil.

The availability of energy also will be the determining factor on how effective humans will be in accomplishing lunar science and exploration objectives. Because the moon’s axis is not tilted like the Earth’s, there are regions of the lunar poles that receive almost continuous sunlight, rather than the 28-day cycle of light and dark found in most regions. This will allow solar power systems to provide electricity to a lunar outpost with much greater efficiency. The LRO cameras will accurately determine these regions of perpetual sunlight by observing them over an entire year.

See the LRO web site for additional info: http://lro.gsfc.nasa.gov/

Come Checkout Constellation on the Move in Las Cruces,N.M.

A mockup of NASA’s nearly 45-foot long launch abort system (LAS) for the crew exploration vehicle, Orion, will be on display from 5 p.m. – 8 p.m. CDT on Thursday, June 18 at New Mexico State University’s “horseshoe” area.

The system is being used to help NASA engineers prepare for the Pad Abort 1 test, which will take place in nearby White Sands Missile Range in November. When astronauts launch to the moon aboard the Orion crew exploration vehicle, the LAS will pull the crew and its module out of danger should a malfunction in the launch vehicle occur on the launch pad or during ascent atop the Ares I rocket. The 90-second Pad Abort 1 flight test will help gather information about how LAS operates in reality.

Other NASA exhibits include a large inflatable tent, handouts, a guest appearance by EVA, one of NASA’s inflatable astronauts, and models of its newest space vehicles, the Orion crew module and the Ares I and Ares V rockets. NASA’s Constellation Program is developing these vehicles, including the Altair lunar lander, to send humans to the International Space Station, moon and beyond after the shuttle retires in 2010.

Folks in the area are invited to catch a glimpse into NASA’s next steps in space exploration. We’ll have NASA employees there from Dryden Flight Research Center in California, Johnson Space Center in Texas, White Sands Test Facility and White Sands Missile Range in New Mexico. The public events are part of the Las Cruces community event held in conjunction with the June 19 groundbreaking of Spaceport America, the world’s first purpose-built commercial spaceport.

Constellation on the Move

NASA is one step closer to launching a flight test of the Constellation Program with Tuesday’s send-off of the Orion jettison motor, a solid rocket motor engineered for the launch abort system of the next-generation spacecraft Orion.

Built for NASA by Aerojet, the jettison motor was shipped from Sacramento, Calif. to the U.S. Army’s White Sands Missile Range in New Mexico for the first test of the launch abort system, called Pad Abort-1. Orion’s abort system will be capable of pulling the crew module away from the Ares 1 crew launch vehicle within milliseconds in the event of an emergency on the pad or during the initial ascent phase.

The jettison motor, a key component of the launch abort system, is designed to separate the spacecraft’s abort system from the crew module after it is no longer needed during launch. A jettison motor function will be needed on every Orion mission.

“The delivery of the jettison motor is a significant milestone for the launch abort system program,” said Kevin Rivers, Orion launch abort system manager at NASA’s Langley Research Center in Hampton, Va. “Delivering this rocket motor is a great reflection of the intense and focused work by the entire jettison motor team.”

The NASA Orion Project is managed out of NASA’s Johnson Space Center, Houston. NASA’s Langley Research Center in Hampton, Va. manages the Orion Launch Abort System element development and integration in partnership with NASA’s Marshall Space Flight Center in Huntsville, Ala.

The components of the abort system are being delivered by Orbital Sciences Corporation, for Lockheed Martin Corporation, the prime contractor for Orion. Aerojet is the subcontractor responsible for the jettison motor.

Engineers Review Solutions to Thrust Oscillation on Ares I

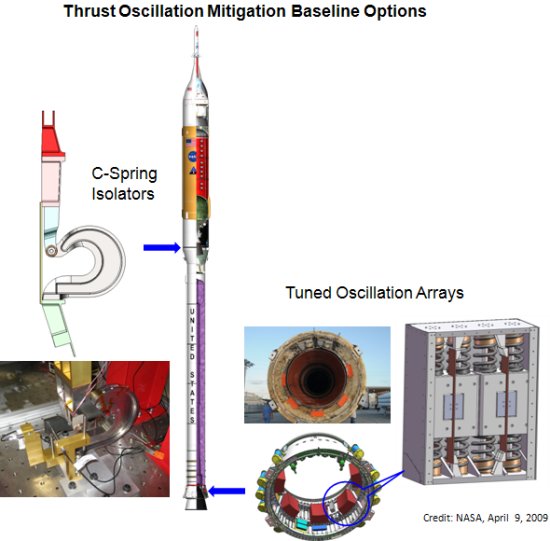

This week, engineers from across NASA and partner contractors gathered at Marshall Space Flight Center to analyze designs to minimize vibrations in the Ares I rocket. During this three-day meeting of the minds, participants showcased tremendous progress toward understanding the physics of thrust oscillation, updates to several candidate mitigation solutions, and results from early subscale testing of candidate hardware. This was not a decision-making session, but an opportunity for engineers and managers to scrutinize proposed solutions.

Thrust oscillation may be felt for a few seconds at the end of first-stage powered flight. Also called “resonant burning,” thrust oscillation is a phenomenon in all solid propellant rockets forcing vibrations through the entire structure, in the case of Ares I, that includes the Orion crew module.

To date, several promising mitigating systems have been identified to counteract vibrations stemming from thrust oscillations. Two primary options are actively under development:

Isolators:

Isolators are C-shaped springs that could be placed between the Ares I frustum and interstage to “detune” the vehicle resulting in less vibration for the crew while maintaining vehicle control stability. The design is based on an existing “soft-ride” technology developed by CSA Engineering, Mountain View, Calif. “Soft ride” technology, which has flown on 17 spacecraft, has been typically placed inside the payload shroud to protect payloads from oscillations. The current Ares design incorporates a ring of 136 C-shaped springs and attach hardware into an isolator module which measures 18.5 inches in height. ATK Launch Systems, located near Brigham City, Utah, is the Ares I prime contractor and is working aggressively with CSA Engineering to mature the isolator design. Moving forward, engineering teams will continue to evaluate the performance of the C-shaped springs and supporting hardware. Engineering design units have been tested on a “shaker stand” which simulates the thrust oscillation loads and demonstrated functionality and effectiveness of this system.

Tuned Oscillation Arrays:

An earlier active mitigation concept called Reaction Mass Actuators (RMA), has matured into a passive solution known as Tuned Oscillating Arrays (TOA). This system will be mounted inside the first stage aft skirt and includes an array of boxes that contain masses suspended on springs which absorb or soak up the vibration oscillation produced during first stage flight. Analysis of the aft skirt has indicated that the existing skirt design can support the TOA approach. Following the recent STS-119 shuttle mission, engineers conducted a fit check with TOA volume simulators and found the solution to be feasible in the existing aft skirt design. Next steps include finalizing bracket concepts to connect TOA boxes to the aft skirt and examining handling processes and equipment needed for ground support. The active RMA concept, which includes powered springs that actively cancel out the vibration, is on hold but available for restart if required later.

Two other alternative thrust oscillation strategies under study as risk mitigation to the baseline include:

A “dual plane” solution:

A dual plane solution would employ two rings of isolators, one located at the interstage/frustum interface and another between Orion and the Ares upper stage. Having redundancy of isolator rings may provide increased “detuning” capability to ensure the Orion does not respond to the oscillations of the first stage motor.

LOX damper:

Engineers are also evaluating a concept called a LOX damper, which uses the fundamental physical properties of liquids to leverage the kinetic energy in the movement of the existing liquid oxygen in the upper stage tank to dampen out vibrations. The devices, installed within the liquid oxygen tank, can engage the mass of the liquid propellant to generate momentum in the fluid itself to counter the vehicle acoustic response and disrupt oscillation. Engineers are evaluating the effectiveness and applicability of this design.

Data analysis:

In addition to discussing specific design solutions, the thrust oscillation team is pouring over existing ground and new flight test data captured from recent shuttle missions STS-126 and STS-119. During recent shuttle flights, sensors placed on both ATK-produced solid rocket boosters measured pressure oscillations, in addition to vibration measurements, on crew seats. Measurements are helping engineers anticipate the magnitude of thrust oscillations forces that may be expected on future Ares I flights.

NASA engineers and astronauts are also evaluating crew situational awareness under various vibration conditions in a simulator at the Ames Research Center. NASA is working to set the final requirements for acceptable crew vibrations – currently a 0.25g requirement that was developed during the Gemini era.

Next steps:

Testing of the isolators and TOA candidate mitigation hardware will march forward. NASA teams will capture additional data from future shuttle flights and from the upcoming test flight of Ares I-X to better understand the risk to the Ares I vehicle and the Orion capsule. Considering all information, NASA will finalize vehicle designs in a thrust oscillation preliminary design review which will define which system, or combination of systems, works best to minimize vibrations on the Ares I vehicle.

What Does It Mean to 'Human Rate' a Rocket?

A lot of people have asked what it means to “human rate” a rocket — to put people on top of a rocket and send them into space. How does an agency like NASA take on this challenge? And what considerations do engineers give human rating as they design Ares to deliver astronauts to the International Space Station by 2015 and for future trips to the moon and beyond?

In a nutshell, human-rating a rocket means that we take our understanding of how the rocket can fail to a higher level of fidelity (than for a non-human rated rocket), and then take steps to prevent failures or have it fail in such a way that the crew can survive the failure (e.g. crew abort).

For NASA, the Ares I rocket is being designed from the outset to fly humans as its primary role vs. modifying an existing system.

To get a little deeper into the subject, I talked with some senior NASA Marshall Space Flight Center engineers, Neil Otte and Gary Langford, who work this challenge for NASA and here’s how they explain it:

Let’s clearly define some of the primary human rated attributes and what they mean. First, human safety is the measure of risk of injury, or loss of life, to any spaceflight personnel. NASA’s policy is to protect the health and safety of humans involved in or exposed to space activities, specifically the public, crew, passengers, and ground personnel. Specifically human rating is involved with the risk to the flight crew. Risks to ground crew and the public are covered under other NASA policy directives and are inherent in all missions regardless of the presence of a flight crew.

A human-rated system accommodates human needs, effectively utilizes human capabilities, controls hazards and manages safety risks associated with human spaceflight, and provides, to the maximum extent practical, the capability to safely recover the crew from hazardous situations. This statement makes up the basic three tenets of human rating: assuring the total system can safely conduct the mission, incorporate design features that accommodate human interaction with the system, and incorporate design features and capabilities to enable safe recovery of the crew from hazardous situations.

Simply put, human rating is a thorough process that consists of many variables being taken into account to safely design, build and launch a crewed spacecraft and return that spacecraft, and its crew safely to the earth. The process begins at program inception and continues throughout the life cycle of the program and includes: design and development; test and verification; program management and control; flight readiness certification; mission operations; sustaining engineering; maintenance, upgrades, and disposal.

We can now look closer at human rating. The first tenet is to safely conduct the planned mission. To accomplish this requires a very careful design. This design is accomplished by a careful examination of the hazards and design features that prevent the hazard known as hazard controls. In the design, the first step would be to try eliminating the hazard; if that is not possible then hazard controls can be put into place to prevent the occurrence of the hazard. Hazard controls can take many forms such as failure tolerance by incorporating redundant or backup systems and components, application of system margins to assure function of the system even under the most extreme conditions, and quality assurance from early material and component selection through final assembly and checkout operations. If applied to a simple example of say a home heating system, the hazard would be that the house is too cold for the health and safety of the occupants. Moving to a warmer climate, however, could eliminate the hazard, if not possible then hazard controls are put into place. Use of redundant systems or components can be applied. For example, many heat pump systems have backup electrical or gas systems to provide heat in the event of a compressor failure or the inability of the compressor to meet the needed heat requirements. The system is carefully sized to provide adequate heat under the most extreme expected winter temperatures for the local climate, and the equipment manufacturer and the installation contractor control quality.

For the Ares I rocket the foundations of the first basic tenet in developing a human rated system have been carefully laid out. Factors such as hazard elimination and hazard controls have been carefully thought out and placed as requirements in the system design. In addition, program management and control places additional requirements on the development to assure adequate system margins, proper test and verification, and safety and mission assurance practices to further minimize the risk to the flight crew.

Even with all the care that goes into the system design and development, the system design must accommodate failure. Sometimes failure is dealt with by simple redundancy that allows mission continuation. In some cases, however, mission continuation is no longer possible and steps must be taken to safely return the crew. For the example of the house, for extreme cold and total system failure, the occupants could choose to leave, go stay with family or friends, or stay in a hotel until repairs are made. In short you remove the humans from the hazard. Ares accomplishes this by incorporation of the launch abort system (LAS). The LAS allows the spacecraft to be lifted away from a failing launch vehicle and allows for spacecraft reentry and rescue of the crew by search and rescue forces.

Launch of a crew to low earth orbit is an energetic process that inherently has significant associated risk. The process of human rating attempts to eliminate hazards, control the hazards that remain, and provide for crew survival even in the presence of failures that expose the crew to the hazards. The Ares Projects team was assigned the task of designing a launch vehicle capable of carrying the Orion crew exploration vehicle, with a crew of four to six astronauts, to the International Space Station AND later support lunar missions. NASA’s top priority is to design and build a vehicle that supports the crew with the safest design possible given real external constraints. The Ares design is a culmination of years of studying the best attributes for a human rated launch system. Every aspect of human rating has been taken into account in the Ares design, therefore the Ares I rocket will be fully human rated, something only achieved by a small fraction of launch vehicles.

The Ares I rocket is three years into its development process and has successfully passed every major design review. Ares is being designed with human rating in mind as the primary requirement vs. modifying an existing rocket. Human rating has been an integral part of the Ares I development since day one.