This week, engineers from across NASA and partner contractors gathered at Marshall Space Flight Center to analyze designs to minimize vibrations in the Ares I rocket. During this three-day meeting of the minds, participants showcased tremendous progress toward understanding the physics of thrust oscillation, updates to several candidate mitigation solutions, and results from early subscale testing of candidate hardware. This was not a decision-making session, but an opportunity for engineers and managers to scrutinize proposed solutions.

Thrust oscillation may be felt for a few seconds at the end of first-stage powered flight. Also called “resonant burning,” thrust oscillation is a phenomenon in all solid propellant rockets forcing vibrations through the entire structure, in the case of Ares I, that includes the Orion crew module.

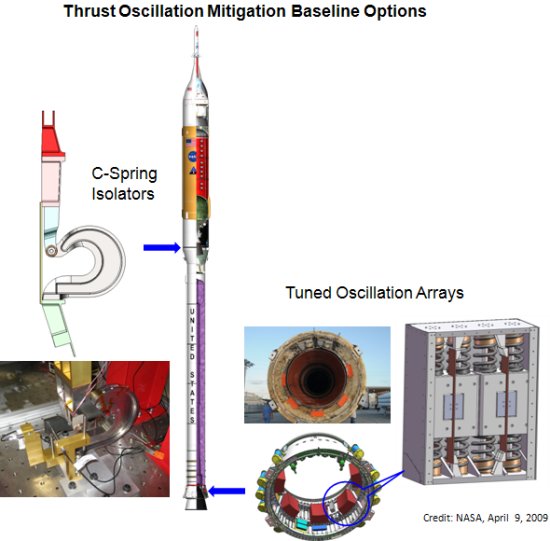

To date, several promising mitigating systems have been identified to counteract vibrations stemming from thrust oscillations. Two primary options are actively under development:

Isolators:

Isolators are C-shaped springs that could be placed between the Ares I frustum and interstage to “detune” the vehicle resulting in less vibration for the crew while maintaining vehicle control stability. The design is based on an existing “soft-ride” technology developed by CSA Engineering, Mountain View, Calif. “Soft ride” technology, which has flown on 17 spacecraft, has been typically placed inside the payload shroud to protect payloads from oscillations. The current Ares design incorporates a ring of 136 C-shaped springs and attach hardware into an isolator module which measures 18.5 inches in height. ATK Launch Systems, located near Brigham City, Utah, is the Ares I prime contractor and is working aggressively with CSA Engineering to mature the isolator design. Moving forward, engineering teams will continue to evaluate the performance of the C-shaped springs and supporting hardware. Engineering design units have been tested on a “shaker stand” which simulates the thrust oscillation loads and demonstrated functionality and effectiveness of this system.

Tuned Oscillation Arrays:

An earlier active mitigation concept called Reaction Mass Actuators (RMA), has matured into a passive solution known as Tuned Oscillating Arrays (TOA). This system will be mounted inside the first stage aft skirt and includes an array of boxes that contain masses suspended on springs which absorb or soak up the vibration oscillation produced during first stage flight. Analysis of the aft skirt has indicated that the existing skirt design can support the TOA approach. Following the recent STS-119 shuttle mission, engineers conducted a fit check with TOA volume simulators and found the solution to be feasible in the existing aft skirt design. Next steps include finalizing bracket concepts to connect TOA boxes to the aft skirt and examining handling processes and equipment needed for ground support. The active RMA concept, which includes powered springs that actively cancel out the vibration, is on hold but available for restart if required later.

Two other alternative thrust oscillation strategies under study as risk mitigation to the baseline include:

A “dual plane” solution:

A dual plane solution would employ two rings of isolators, one located at the interstage/frustum interface and another between Orion and the Ares upper stage. Having redundancy of isolator rings may provide increased “detuning” capability to ensure the Orion does not respond to the oscillations of the first stage motor.

LOX damper:

Engineers are also evaluating a concept called a LOX damper, which uses the fundamental physical properties of liquids to leverage the kinetic energy in the movement of the existing liquid oxygen in the upper stage tank to dampen out vibrations. The devices, installed within the liquid oxygen tank, can engage the mass of the liquid propellant to generate momentum in the fluid itself to counter the vehicle acoustic response and disrupt oscillation. Engineers are evaluating the effectiveness and applicability of this design.

Data analysis:

In addition to discussing specific design solutions, the thrust oscillation team is pouring over existing ground and new flight test data captured from recent shuttle missions STS-126 and STS-119. During recent shuttle flights, sensors placed on both ATK-produced solid rocket boosters measured pressure oscillations, in addition to vibration measurements, on crew seats. Measurements are helping engineers anticipate the magnitude of thrust oscillations forces that may be expected on future Ares I flights.

NASA engineers and astronauts are also evaluating crew situational awareness under various vibration conditions in a simulator at the Ames Research Center. NASA is working to set the final requirements for acceptable crew vibrations – currently a 0.25g requirement that was developed during the Gemini era.

Next steps:

Testing of the isolators and TOA candidate mitigation hardware will march forward. NASA teams will capture additional data from future shuttle flights and from the upcoming test flight of Ares I-X to better understand the risk to the Ares I vehicle and the Orion capsule. Considering all information, NASA will finalize vehicle designs in a thrust oscillation preliminary design review which will define which system, or combination of systems, works best to minimize vibrations on the Ares I vehicle.

All very logical and admirably clever. But; why not use a launcher that doesn’t HAVE Trust Oscillation or a $30 billion development cost in the first place? — Delta IV-Heavy (with RS-68A engines), Atlas V-Heavy, Jupiter/Direct?

No? Anyone?!

Sigh…

HI I’AM WILLIAM E. PEREZ AN ELECTRONICS ENGINEERFROM TAMPA,FLA.

I SEE WE HAVE SEEN IN THE PAST THESE DESIGNS USED AND HAVE TO BE INCORPORATED TOGETER IN SHUTTEL AND AS FAR BACK AS APOLO .IT IS NEWER RESEARCH NEEDED TO USE A NEWER AND BETTER STRUCTURE OF CHANGE IN THIS TYPE OF STABILIZATION. MAYBE SHOCK POLLS TO UPPER AND LOWER RING ASSORB THE VIBRATION WOULD A DESIGNE TEST RESULTS HELP UP THE SYSTEM SCALING TO KNOW WHAT SCALE WHERE ON .

THANK YOU;NASA

Is vibration in an SRB as it approaches burnout a function of its slenderness ratio – i.e., does vibration increase with the slenderness of the rocket?? Is the problem much worse in the 5 segment Ares I SRB compared to a 4 segment Shuttle SRB, and would it be much less in a 3 segment rocket??

Except in missiles, where shelf life and instant readiness are the only considerations, it’s beyond human comprehension that anyone would consider using solid-fuel rockets for main propulsion in this day and age. (And “this day and age” includes 1973 or so, when the design for the Shuttle was being finalized.)

Use a Delta 4 manrated or use the Direct 2.0 approach.

This spring deal is way out in left field.