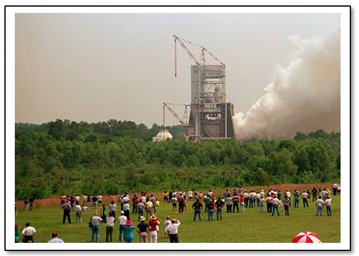

Okay, so now you’ve got a great big rocket engine. What are you going to do with it? Well, fire it, of course. Make great big and noisy smoke and fire. There’s really not much that is more thrilling than an engine test…although, I guess, launches qualify (says the old engine guy reluctantly).

Engine Test at NASA Marshall Space Flight Center

But where are you going to do this? It’s not like you can do it in your garage. You’d blow away your entire neighborhood in the matter of a few seconds and the authorities tend to frown on such antics. Take a look (and listen) again at the video clip from the “What is a Rocket?” blog article to get an idea of what I’m talking about. Also, it’s not even like you can simply hire a company that specializes in testing stuff and there are many fine companies that do just that for all kinds of products big and small. No, rocket engine testing is an endeavor that requires its own dedicated facilities and infrastructure.

Over the past fifty years, NASA has developed a number of rocket engine test facilities, but by far the single largest and dedicated site is in southern Mississippi, Hancock County to be exact, today called the NASA Stennis Space Center (SSC). This facility is just about an hour from New Orleans. It is in a very secluded, woody bayou area far from any population centers. And that was the point when it was established. Given the size of the place needed to test rocket engines and rocket stages and given the noise that such testing makes, having no neighbors is basically a requirement.

Testing for the J-2X engine is currently planned in the “A-Complex” test area. That area is composed of three test stands. There are stands A1, A2, and A3 (no, it’s not an especially colorful naming scheme, I admit).

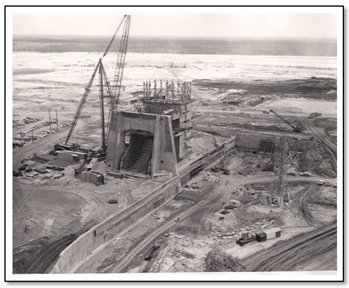

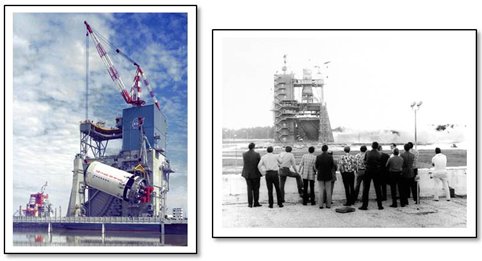

Stands A1 and A2 were designed to look like and function like the large test stand here at the NASA Marshall Space Flight Center. They were built in the 1960’s and were originally stage test facilities to accommodate testing of the S-II stage, the second stage of the Saturn V launch vehicle that took humans to the moon. The S-II stage was, of course, powered by the original J-2 rocket engine. Then in the early 1970’s, these two stands were converted into single-engine test stands to facilitate the development of the Space Shuttle Main Engine (SSME). Test stand A2 remained dedicated to SSME up until last year. Test stand A1 over the last thirty-five years was used primarily for SSME, but it was also used in the late 1990’s for the XRS-2200 linear aerospike engine development (which used a number of heritage J-2 and J-2S component designs) intended to support the X-33 vehicle.

Test Stand A2 Under Construction, Early 1960’s

S-II Stage being Hoisted into A2 in 1967 and the First SSME Test on A1 in May 1975

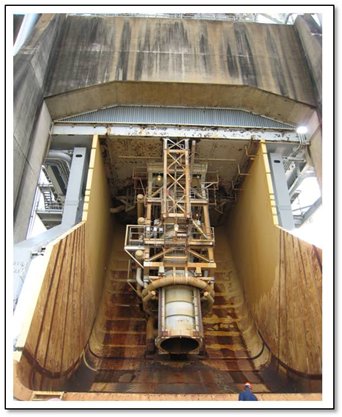

Test stand A3 is a new facility currently being built specifically to accommodate development of the J-2X engine. It is unique in that it simulates the atmospheric pressures at high altitudes. Because the J-2X is being designed for maximum performance and for engine start at high altitudes, it is only within such a test facility as A3 that the complete configuration of the J-2X engine can be tested. The altitude simulation capability is produced by encapsulating the entire engine within a test chamber and using a system of steam ejectors to “suck down” the chamber using the Bernoulli effect familiar to students of fluid dynamics. Basically, what you have on A3 is a series of rocket engines, powered by liquid oxygen and alcohol, used to make a huge amount of high-velocity steam that creates a low-pressure environment into which the J-2X fires (itself also making a huge amount of steam). When A3 is up and running, the J-2X testing conducted there is going to be even more impressive than the usual engine tests.

Test Stand A3 Under Construction Today

The J-2X puts out approximately 300,000 pounds-force of thrust when fully configured and operating in space. As currently rigged, each of these three test stands can handle 600,000 pounds-force of thrust and, with some modifications, significantly more (the current thrust measurement systems being the limiting factor). Back when they were testing the S-II stages on A1 and A2, those stands were seeing nearly one million pounds-force of thrust with five J-2 engines firing simultaneously.

Within the last month, I had the opportunity to tour NASA SSC and see the progress of the work being done on these test stands to support the J-2X test campaign. Below are a series of photos with some accompanying commentary.

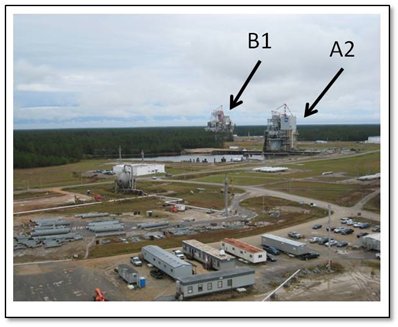

This is a shot taken near the top of stand A3. They have not yet built in the elevator so I know firsthand that the walk to the top is just about 23 flight of stairs, give or take a couple. I’ve marked stand A2 and also stand B1, which is currently used for RS-68 engine testing that supports the Delta IV launch vehicle. Stand A1 is off to the left, out of the frame of this picture. The low white building in the middle of the picture is the control room from where they conduct engine tests on A1 and A2. The control room for A3 will be in a different building.

Above is a picture of Jason Turpin (Liquid Engine Systems Branch, ER21, NASA MSFC) and Rick Ballard (Upper Stage Engine Element Systems Engineering and Integration Manager) standing on the Level 5 deck of stand A1 with the A3 construction site in the background. The water that you see behind them is part of a canal system that runs throughout the test area. On these canals they bring in barges filled with the propellants used for the testing. Back in the day, these canals were used to float in the assembled Saturn stages. This is not, however, necessary for engine testing since a single engine can be loaded onto a truck.

Overall, this tour of the facilities showed that NASA SSC is making tremendous progress in getting the test stands ready for the J-2X development test series campaign. In only a few months, we will be making smoke and fire (mostly steam!) and rumbling the acres of swampy woodlands that surround the site. I can hardly wait!

Cool! Do you know where I can see higher-resolution versions of some of those archival pics of the Saturn and SSME tests?

Thanks for explaining how engines are tested; the part on how vacuum conditions are simulated was very interesting — did not know that was even possible. It was stated that two of the test stands were used for the SSME for a period of 35 year; possibly you could also explain why it or any other type of engine would need re-testing over its period of use.

This is a really interesting blog, please keep it up.

Maybe sometime you could also run an article on the software you use, eg the computer modelling I presume you have for predicting how the engine will behave under different conditions. I admit this is probably a minority interest.

@ Kai: I pulled those old pictures from NASA picture archives available on the web. Took about five minutes with a search engine and some specific terminology (engine test, S-II, A1, A2, etc.).

@ Steve: I worked on the SSME project off and on for a dozen years. You have to realize two things about that engine. First, it evolved dramatically over those 35 years. Other than the nozzle, just about every other major component on the engine was upgraded, usually for greater reliability and safety considerations. Second, SSME is a reusable engine making it truly unique. Because of that, there are times when the hardware needs to be torn down, refurbished, reassembled, and re-accepted for flight. To ensure workmanship, all flight hardware is green run prior to being installed on the vehicle. Hope that helps.

impressive facility. But I know that NASA GRC has a test station (near Sandusky, OH) that has an altitude test chamber capable of doing what you are describing for A3. Is there something that makes A3 unique compared to GRS’s testing? I know they tested entire Centaur upper stages in this facility. Thanks!

Regarding the Plum Brook facility, operated by NASA GRC in Sandusky, OH. Yes, that is an altitude simulation facility for engine testing. However, it’s a matter of scale. The Plum Brook facility supports testing of an RL10 engine, which has a thrust level of about 24,000 pounds force. The J-2X has a thrust level of nearly 300,000 pounds thrust. The current systems at Plum Brook simply cannot keep up with that much exhaust being generated. It would fail to maintain altitude simulation. We looked into modifying the Plum Brook facility or possibly going to AEDC in Tennesee (where tests were done with the original J-2 forty-some years ago), but the most cost effective answer in the long run for the agency was to pursue the construction of A3. Hope that helps.

Very powerful and expensive engine.I like it