It’s03:04 in the morning and, after having completed the last pre-flightoperations, the NASA ATTREX Global Hawk is now ready to fly. In fact, some ofthe payload instruments (such as DLH, HUPCRS, and mini-DOAS) require detailedfine-tuning and calibrations that can be performed only few hours before atakeoff. In the picture you can see the Global Hawk being pulled outside thehangar in preparation for takeoff which is scheduled at 07.00AM. Next blog willbe live from the Global Hawk Operation Center!

Month: January 2013

ATTREX: Third week of work

Day14: Combine System Test (CST)

Today was the day!!! Wefinally performed our Combine System Test. In general, the test ran smoothly,and everything went as I expected. However, I have to confess, I could not helpbut feel anxious the entire time. I am not sure why. I have been doing pre-CST,and bench test for almost a month, but I believe every time is different.

Today, I was lucky tocount with the assistant of one of our engineers (Roger). He kept an eye on allmy movements, so I felt a little bit more confident, but still, I think anxietywon the battle.

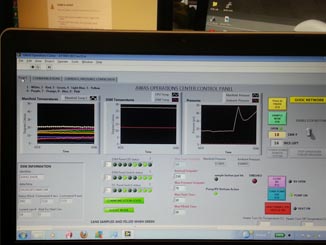

Once the test finished,I finally could relax and have some fun! I was waiting to see the results fromthe computers. We usually can take a look at the data from our ground computerat any time, but sometimes, it is better to see the results from the aircraftcomputer (you know, if satellite communication fails, the aircraft computerstill contains most of the data). I cannot complain; the results from the testwere good. We were able to send commands from the ground and our instrumentexecuted them perfectly. We tested the heaters and the pumps. We did not takeany sample since we were on the ground. But we are confident that if theheaters and pumps worked, the canisters valves will also work!

Let’s just wait and see what will happenduring our Range flight!

ATTREXteam at the Global Hawk Operation Center during CST. Roger (front row 3rdsit from left to right) keeping an eye on AWAS computer during CST.

Rogergetting ready to collect the CST data from our instrument computer inside theaircraft.

Day15: Pre-Flight

I’m so excited;tomorrow will be our first time in the air. So, today we checked our instrumentone more time. In our pre-flight, wecheck all bolts and electrical connections in our instrument (of course, wedon’t want the instrument to jump around during the flight). We also set up the instrument computer insidethe aircraft, and pump the inlet to verify that there are not leaks. The procedure takes like 45 min.

Rich and Roger werewith me during the pre-flight (I believe six eyes are better than two). Ipersonally can’t wait for tomorrow’s Range flight. It would be a short flight (5 or 6 hours),but it will be the opportunity that I was waiting for. I will finally collectsome samples!!!

Our “home made” device to check the inletduring Pre-flight.

Day16th: Range flight…but wait, not so fast!!

Well, here we are!Range flight Day! How excited…

Today I woke up around3:40am to be ready to pick up Roger at 4:40 am (we had to be at the Global Hawkoperation Center at 5:00 am) Flight was scheduled to take off at 7:00 am. Once we got to the Global Hawk we noticedsomething strange…not all the pilots were in the Flight Operation room, andthrough the screen, we just saw one person around the aircraft (there are usuallya lot of people around preparing the Global Hawk for takeoff) Thus, 5 min afterI set up my ground computer, one of the network engineers broke the news: FLIGHIS CANCELLED!…Whaaaaatttt???? But I was so ready for this flight (Bummeragain!!!), Well, it seem like the aircraft power pallet was not working and wecould not fly without that data information. Thus, the plan will be to fix thedevice and proceed with our Range flight tomorrow (same time, same place).

As Jochen (a member ofthe Mini Doas group) said: “It was a good drill”…ohh yes indeed!…now I knowhow terrible will be to wake up again at 3:00 am…but hey!, let’s look at the bright side…did I mention howbeautiful the sunrise is at Dryden? Hereare some pics…enjoy while I go back to sleep.

Sunriseat Dryden!!!

Day17: Let’s try this one more time

Well, here we areagain! Range Flight Day!…not too excited as I was yesterday, but ready to goONE MORE TIME.

I woke up pretty earlyin the morning (3:00 am), just to find out that the flight was delayed. Some documentationfor yesterday’s repair was needed before takeoff. Thus, while we waited,mechanics from Northrop Grumman checked the power pallet ONE MORE TIME. After a couple of tests, they realized thatit was not working properly. They would need one hour more to complete thework. Well, after some time calculations, the Global Hawk Payload Manager (DaveFratello) realized that a delay in takeoff, would not allow us to land on time.Thus, our Range Flight was postponed ONE MORE TIME…

Hopefully we will be in the air tomorrowmorning. You know, third time’s the charm.

Mechanicsfrom Northrop Grumman testing the power pallet.

Day18: third time’s the charm

Finally, Range FlightDay!…More than excited, I just felt like I have to get this done. We havebeen trying to fly for three days, so it was time for me to get some airsamples.

While the aircraft wastaxiing, I started to feel really anxious. I was wondering if I did mypre-flight correctly. I was sure I did, but I could not help to have my doubts(I think it is normal when you feel so nervous). By the time we requested topower up our zone I decided to get rid of my fear and focus on my work. Yes,after we powered up the instrument, we started to get our “packets” through thesatellite; uffff… what a relief!

I took my first sampleapproximately 15 min after takeoff. Ifelt really glad when I saw the plots on my computer and I noticed that Iactually drew some air into my canisters.

Since the flight wasreally short (5 hours) I had to take samples every 3 minutes in order tocollect the 90 samples that we usually collect during a science flight.However, during this flight, we also performed a power test, since the GlobalHawk managers needed to know the power consumption of each instrument. Thus, inthe middle of the flight, they decided to power down each of the aircraft zonesand take a look of the changes on currents. Unfortunately for us, ourinstrument is the one that consumes most of the power…this mean, that forsecurity issues with the aircraft, we will have to turn off AWAS every time theaircraft descends. To be honest, my team is a little concerned about it. Westill do not know how the instrument will behave with this sequential powerdown and ups. But we will figure it out in our next flight…so stay tuned.

AWASground computer during sampling. See how the pressure changes (white line onthe 3rd plot from left to right) as the canister drew air.

Oneof the monitors at the Global Hawk Operation Center (GHOC) showing our aircraftready to land (welcome home baby!!!)

Day19 through 21: Data analysis

And now its time to seewhat I got!

One of the first thingswe do after each flight is to extract the data from the aircraft (part of ourpost-flight procedure). From the values collected by the aircraft computer Iverify if all canisters open and collect sample. However, there is a lot ofinformation that I need to gather from the data e.g. where the samples werecollected, how long it took to the canisters to fill up, what pressure eachcanister reached during sampling, etc. So I spend the next couple of dayslooking at the numbers and plotting the results.

During my preliminarydata analysis, I found out we missed one of the most important “packets”, theIWG1 (a text file that record aircraft information such as altitude, longitude,latitude, etc) , thus I also spend a lot of time exchanging e-mails with oursoftware engineer in order to solve this problem before our next flight.

There is a lot of workto do for the next couples of days, and this is really exciting!!!. First, weare going to test our analytical instrument (a Gas-chromatograph-MassSpectrometer) on the site. This instrument will allow us to know what compounds(and how much of them) are in the air samples collected. If the instrumentworks as we expected, we will save time (and $$), as for the followingcampaigns we won’t need to ship our canister back to Miami to performed thiswork. Thus, keep your fingers crossed (all of them!!!)

ATTREX: Allow me to introduce: mini-DOAS!

Today, I would like to introduce you to my instrument: mini-DOAS!

You must know that scientists love to use acronyms to name instrumentsor even experiments (such as the ATTREX mission), so let me spell out for you whatmini-DOAS stands for: mini- Differential Optical Absorption Spectrometer. Ittakes its name from the well established spectroscopic technique (differential opticalabsorption spectroscopy) used to identify and measure amounts of differentgases. So what is mini-DOAS? Mini-DOAS is a remote sensing instrument whichuses scattered sunlight in the ultraviolet (UV), visible (VIS), andnear-infrared (NIR) spectral range to measure the concentration of atmospherictrace gases such as bromine monoxide (BrO), ozone (O3), nitrogen dioxide (NO2), oxygen dimer (O4), and water vapor. Thesetrace gases are very important because they contribute to the formation anddestruction of ozone in the atmosphere of our planet.

In the picture you cansee the mini-DOAS instrument integrated in the payload area of the NASA GlobalHawk. Briefly, the main components of our instrument are: a vacuum sealed box containingthe spectrometers and the optical fiber bundles connecting them to the telescopesmounted on the outside of the aircraft’s fuselage. It’s important to know thatthe telescopes have the ability to rotate so that they can point towardsdifferent viewing angles and therefore collect more information.

As you can see, theinstrument is now ready to fly and, indeed, we have already begun the countdownto tomorrow’s science flight!

ATTREX: An introduction to Max's blog

Hello! My name is MaxSpolaor and I am a UCLA/NASA Postdoctoral Scholar working on the NASA ATTREXmission as part of the Mini-DOAS instrument team.

Prior to joining the UCLA Department of Atmospheric and Oceanic Sciencesand the NASA Airborne Science Program I was a Research Fellow and InstrumentScientist at the Australian Astronomical Observatory in Sydney, Australia. Ireceived a Ph.D. in Physics in 2010 from Swinburne University of Technology in Melbourne,Australia and a B.Sc. in Physics and Physical Technologies from the Universityof Trieste in Italy.

In the next weeks, as the NASA ATTREX mission unfolds, I will make useof this blog to share with all of you my experiences, insights, hopes andexpectations of such scientific endeavor and, of course, to keep you posted onany discovery!

A video interview with Max Spolaor

ATTREX: Second week of work

Day 7: A way to do it wrong!

Well,besides continuing to clean canister (with my warm oven), today we had ourfirst communications test (IT test). This test evaluates if our instrumentreceive the commands from our ground computer, and if it communicates throughthe right satellites. The procedure is very simple. The instruments are poweredup one by one and the network engineers check for the signals inside theaircraft and through the satellites. In our case, we use our ground computer tomonitor the signals by receiving something we call “engineering packet”, arecord of all the commands we send and receive from both aircraft and groundcomputers. During the test, I saw how all instruments were tuned on and workingfine, until finally our instrument was turned on but, we did not see any engineeringpacket (bummer!!!). I couldn’t help but wonder…what were wrong with ourinstrument? I felt extremely disappointed. I performed several bench tests andboth computers communicated perfectly. I also double checked that the aircraftcomputer was turned oncorrectly before performing the test, so, what went wrong? I thought a lotabout it while I was walking back from the operation center to the hangar, butthere was something else that really bothered me…I think it was the embarrassmentbecause our instrument was the only one that didn’t work…Luckily, we wereable to go to the runway and check our aircraft computer. We realized then,that the aircraft computer did not open the default program so it wasimpossible for it to communicate. Once we solved the problem and confirmed thateverything was working fine, I decided to get rid of my embarrassment by rememberingthe great words of Benjamin Franklyn: “I didn’t fail the test, I justfound 100 ways to do it wrong.”

The aircraftbeen pull out from the hangar to runway for IT test

Global Hawksatellite antenna

Members ofeach team in the Global Hawk Operation Center during IT test.

Day 8 and 9: Sick Days!

It is Wednesday, Jan 9th, exactly one weekworking at Dryden. The job has been going really well, but now,it is me who does not feel well.

I took some time off to recover from a terriblepoison food. Being sick during my field work has been one of my worst experiences.I honestly tried to rest on my hotel room, but subconsciously, I was stillthinking about how things were going in the hangar. Fortunately, things wererunning smoothly and my team did not need me around. I bet interesting thingshappened at Dryden, but more excited things are about to happen!

Day 10: Here is the plan!

I came back to work today. I kept cleaningthe canisters (fortunately the last set), but the most interesting part of theday was our first Science meeting. Around 1: 00 pm all the scientists met withthe Principal Investigators (Eric Jensen and Lenny Pfister)to talk about flight plans, science targets and meteorological issues. Itseems like the flight strategies are pretty clear, and the weather seems tocooperate for the flight proposed for next week. Let’s just hope we can completeall the combine system tests on time, thus we can be ready for our first scienceflight!!!, and let me enjoy the weekend, which weather seem to be prettyawesome too!!!

DAY 13: CST,PRE-CST, PRE2 CST…which one is it?

Well, to be honest, today I felt like I wasin an operating room, but outside…in the waiting area. We started our morningready for a CST (combine system test), a communication test that involved thescience teams and the aircraft pilots. Unfortunately, the Ku- band system failed for almost half of the day and we did not have any other option thanwait until it was fixed…Yes, these things happens and it is no one fault…forthis reason you should always be prepare and expect the unexpected during fieldwork.

Around 3:00 pm Ku-band became operative.However, the CST turned into a PRE-CST (the same exercise but w/o pilots) asthe pilots were not available at the moment. The bright side of this test was the successful result of ourinstrument. We were finally able to communicate through both bands KU andIridium.

AWAS ground computer during Pre-CST (yes!!! It is working)

ATTREX: First week of work

Day 1: Welcome to a new challenge

Welcome to my blog and to my amazing journey on ATTREX 2013.

I feel excited aboutthis new campaign, even though it happens immediately after my New Year’s partyand I haven’t had enough time to rest!

Today, I flew from Miami, FL to Los Angeles, CA on a long 5hours flight. During this time, I have not only watched movies, solvedcrosswords, and listened to some music; I also thought about my expectations forthis campaign. As a scientist, I have aninfinite number of goals. For example, I would like to develop my research skills,and/or to improve my performance using the basic knowledge I acquired lastyear. But as a member of the ATTREX team, I only hope for the fieldwork to runsmoothly. The problem is that there are some things you simply can’t plan for during a field work, and unforeseen problemswill definitely change our mission plans. In this context, I believe that myonly option is to be optimistic and to think positive! Since graduate school I learned that obstaclesare the stimulus that impels our actions to successfully complete our work, andI am sure that ATTREX 2013 won’t be the exception to this rule. Thus, welcometo this adventure and to the new challenge that is waiting for us.

Entrance of Dryden Flight Research Center (Who saysDisneyland?… actually, it is HERE where the “magic” begins)

Day 2: Hands on the aircraft (Kinda!!!)

Today was my first day at Dryden. It was nice to come backand see all the familiar faces and wish them Happy New Year.

Our day started pretty early in the morning (around 6: 00am). I was still tired from my trip, but I like to get my hands on theaircraft, so I wouldn’t miss it for the world! Our job today was to install ourinstrument inside of the aircraft to complete the weight and balance. However,since it was the first installation for the mission, Elliot (our instrument PI)took charge. I then played the role of assistant, which it is not that bad…atleast I was still able to touch the aircraft (literally). Thus, as an assistantI was just handled the modules and the necessary tools for the AWASinstallation. The problem was that I wasn’t too familiar with the name of thetools in English (oops!). Luckily, our brilliant mechanic Steve was nearby, andhe handled most of the tools for me…Thank you Steve, you certainly avoided my awkward moment. Despite this embarrassingmoment (that I think nobody knew until I wrote it), I still feel proud of mylabor! Today I’m not just a simple chemist; I’m a chemist who knows the name ofthe tools. That’s the beauty of ATTREX,there is always something new to learn!!

AWAS modules ready for installation inside aircraft

Elliot Atlas inside of the aircraft during AWAS installation

Day 3 through 6: First thingsfirst: Let’s clean some canisters!!! (WithHEAT!)

I finishedmy week and started the new one by cleaning canisters!!! This is definitely oneof the most important steps to assure the precision of our work. Thus, I haveto be really careful about the procedure and keep track of all the steps. Theprocedure is very simple, although sometimes it takes a couple of hours to bedone. Basically, I introduce the canisters inside an oven and pump out the airthat was previously setting inside them. Then, I introduce clean nitrogen andpump it out again. I repeat this process several times, so it keeps me busy formost of the day. However, one of the greatest advantages of doing this work isto be close to the oven. To be honest, the temperatures in the desert have beenextreme!!, and I think the hangar has a peculiar temperature regulator… It canonly be set to cold or “super “cold. So, if you are planning a trip to Drydenduring winter time, just be sure to bring extra coats or your own oven!!!

Thecleaning system (OVEN included!!!)

ATTREX: Introduction to Maria's blog

Maria Andreyna Navarro Rodriguez:

I am a postdoctoral associate from the University of Miami. During year and a half, I haveworked in the ATTREX project as a team member of the Advanced Whole Air Sampler(AWAS) for the Global Hawk aircraft. My main role is to help with the sampling, analysis, and data interpretation of tracegases collected by our instrument. My educational background includes a BS inChemistry from the Central University of Venezuela, and a PhD in EnvironmentalScience from Indiana University. Myprevious work experience involves atmospheric chemistry research of differentlevels of the atmosphere, focusing on the analysis of particles and gases.

The purpose of my blog about ATTREX is to share myperspective about this experience, and I hope thatmy writing will be engaging for those people who might think of science assomething too abstract and complicated. Science can alsobe fun!

Check out this video if you want to know a little bit more about me.

https://www.nasa.gov/multimedia/videogallery/index.html?media_id=158575841

New Zealand Prime Minister Visits Icebreaker Drill

One of the most frustratingly valuable aspects of testingand working in extreme environments is that nature is unpredictable, out ofhuman control, and hence likely to create unexpected problems and opportunities. Today, that led to postponed tests buta chance to brief the Prime Minister of New Zealand, John Key, who with hiswife Bronagh Key had themselves planned to go today to the South Pole.

However, this morning featured 25F/-4C temperatures, 20ktwinds with powdery snow (we now have about 8 in on the ground) and lowvisibility, so both air travel and our tests outside camp were scratched. Thisled the PM and his entourage to visit the science (Crary) lab facility thismorning.

Team members (Glass, Marinova) brief the Rt. Hon. John Key and his wife Bronagh during their tour of Crary Lab today.

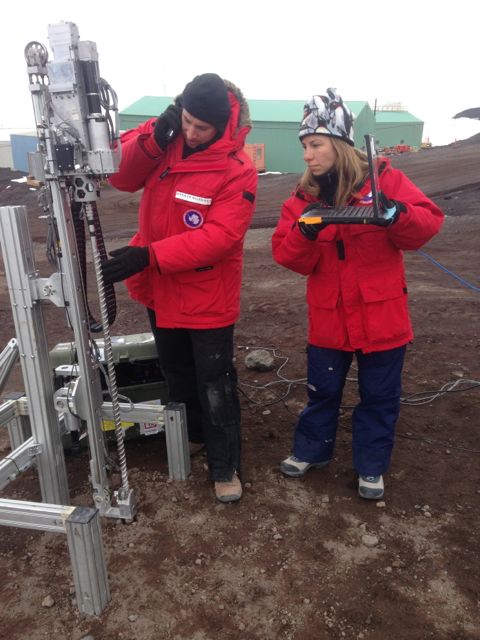

We struggled to get our morning E/PO done, given the weatherconditions and an unexpected software problem. We recovered in time for a Santa Rosa, CA charter school andits students (mostly homeschooled) to operate the Icebreaker drillremotely. An article is in theSanta Rosa Press-Democrat (http://www.pressdemocrat.com/article/20130118/ARTICLES/130119457/1350?Title=Hands-on-look-at-a-mission-to-Mars). Since we had gotten the drill running for the students, it was easy toremove the tarps and do a show-and-tell 90 minutes later for the Rt. Hon. Mr.Key. It helped that we were thelast stop on his laboratory tour, as there was some time left forquestions.

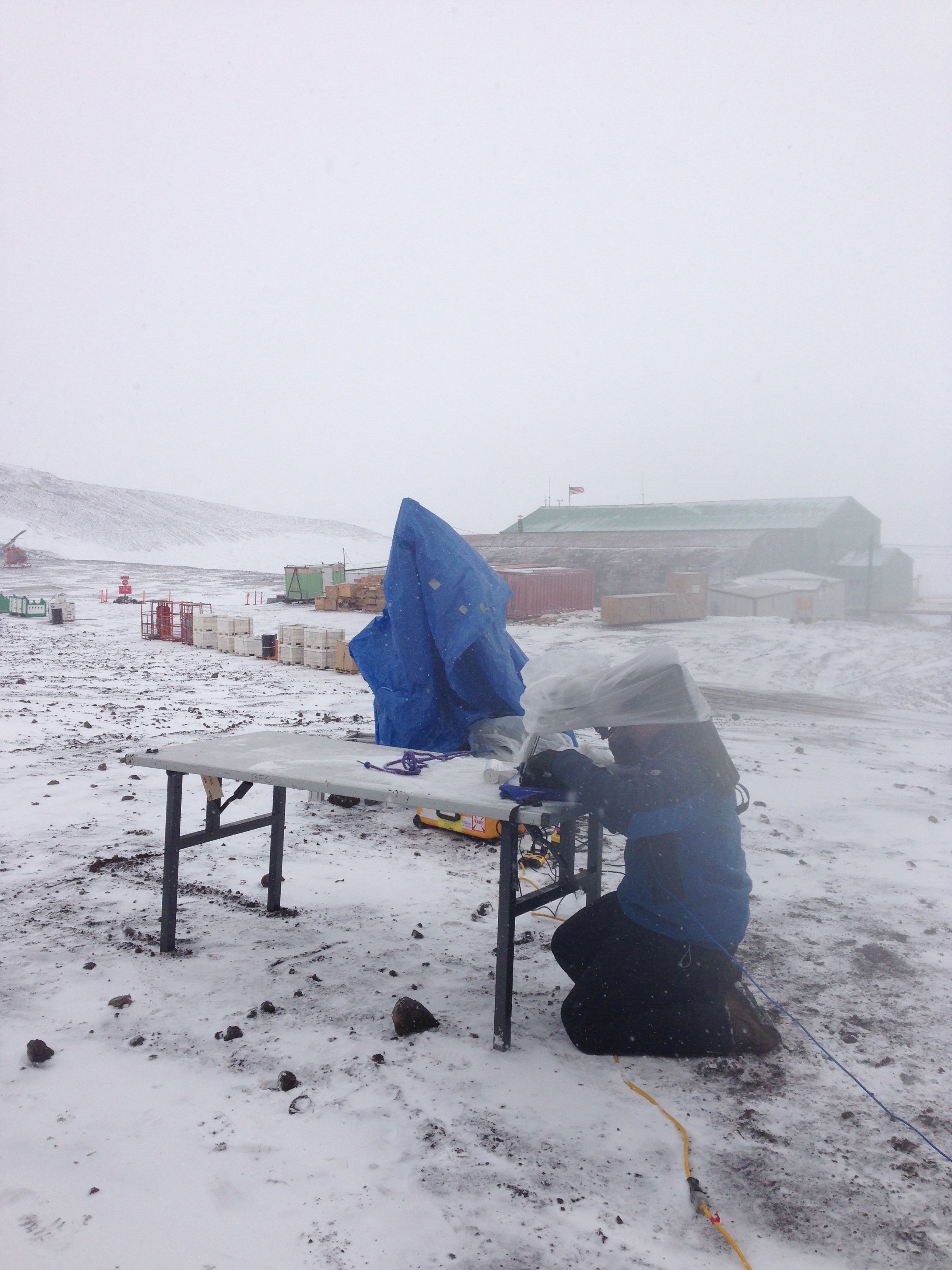

In challenging working conditions, Bolek Mellerowicz configures the Icebreaker drill control software for an educational outreach session this morning, prior to removing the tarp protecting the drill.

Hence weather frustrated our original plans… but also createda unique opportunity, as long as we could be flexible and adapt to changingcircumstances (in the best NASA traditions).

Icebreaker Remotely Operated by Schools

One of NASA’s goals, in addition to furthering humanity’sreach in aeronautics and space, is to educate and foster interest in science,mathematics and engineering by the next generation. A small percentage of every funded research proposal istypically targeted at “Education and Public Outreach”, or E/PO.

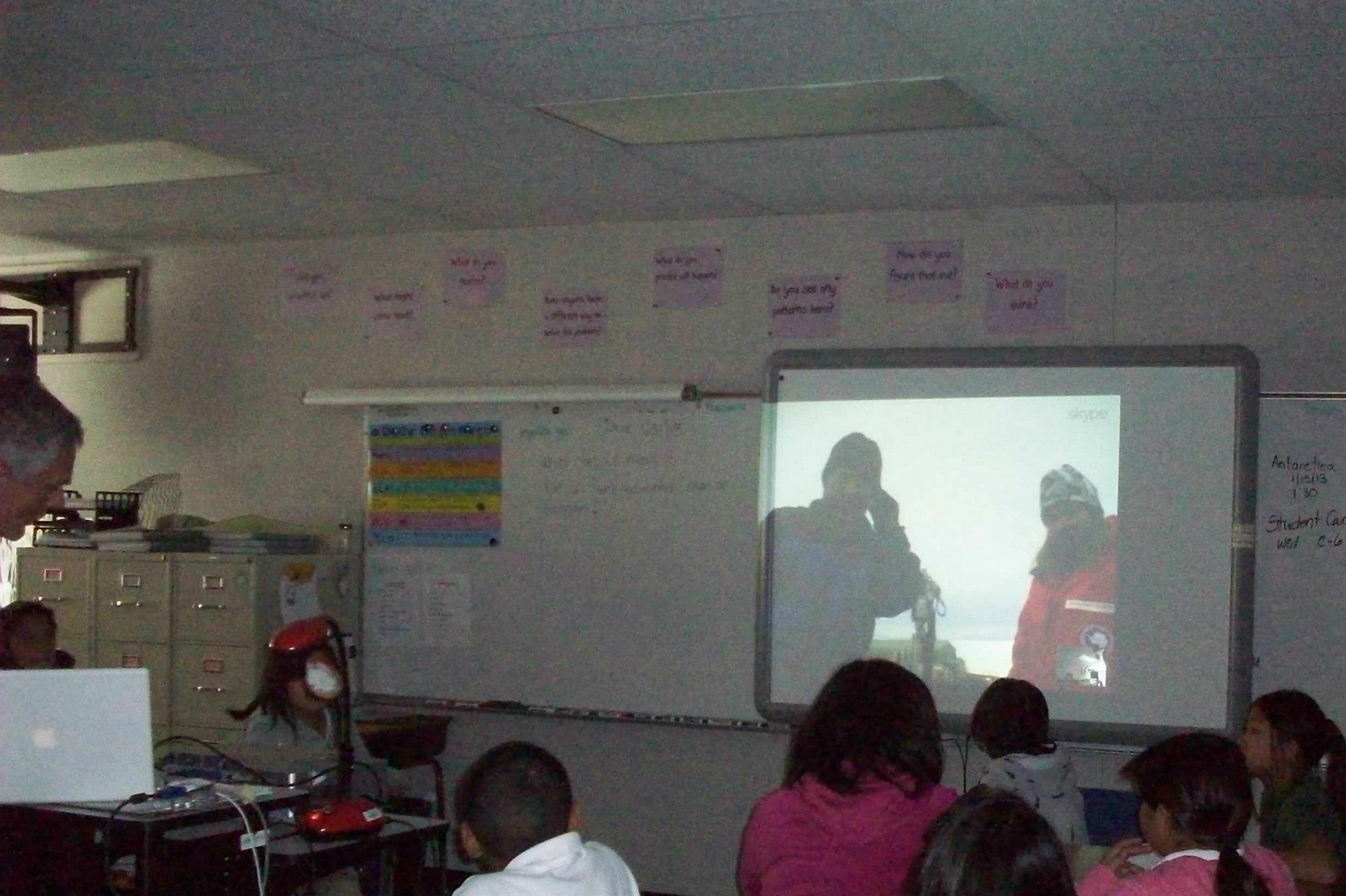

One of the ways that the Icebreaker team is reaching out tothe next generation is through live video sessions with school classrooms.These include audience-tailored briefs by team members, given live fromAntarctica, with classroom questions and answers. And… we let the students remotely operate the Icebreakerdrill, here in McMurdo, from their classroom. This often gets a lot of enthusiastic responses fromschoolkids.

While half of the Icebreaker team is already in UniversityValley doing science, here in McMurdo we are finishing drill checkouts, minormaintenance and doing E/PO back to the US. Three days ago we did our first hour-long session with an Arizonahigh school (Verde Valley HS, near Flagstaff). We managed this despite repairing a broken wire on the drillthat had us working behind the scenes, while live, and outdoors in high 30ktwinds and blowing snow. Two daysago we did three sessions: with amiddle school in New York City; another group of mostly-Native American (Yavapai-Apache) 6thgraders at an Arizona school; and with a group of mostly Vietnamese and Hispanic kids at an elementary school in south San Jose,CA.

Classroom view from Meadows Elementary, San Jose, CA (Glass, Marinova). [courtesy L. Haven]

Yesterday wedid four sessions, with the first two in Pasadena, CA: Jackson Elementary and Eliot MiddleSchool. The first session includedlocal Los Angeles media coverage (see NBC http://www.nbclosangeles.com/video/#!/on-air/as-seen-on/Pasadena-Students-Help-Operate-NASA-Drill/187231281as well as http://altadena.patch.com/articles/altadena-students-help-control-nasa-mars-drill-antarctica-jackson-elementary-school-pasadena-unified-school-district#video-12998220). Followed by a school in Pleasanton, CA and then a link to a company who hadexpressed interest (SpaceX, in Los Angeles).

We have one more E/PO session scheduled this week (tomorrowat 11am PT, 8am Saturday for us) with a charter school in northern California(Santa Rosa). Then we will finishdrill and robotics testing near McMurdo this weekend before we join the rest ofour colleagues in University Valley. Two team members (Marinova and Goordial) will leave for there tomorrow,after the E/PO session.

Explaining drill hammer actuation to a Pasadena middle school (Mellerowicz, Marinova).

We are tentatively planning a few E/PO sessions afterreturning in early February from University Valley, most likely on 4 February(PT). Contact chris.mckay@nasa.gov if you’reinterested, as he’s handling the schedule coordination back at NASA Ames.

Happy Camper for Icebreaker members

Not everyone who arrives in Antarctica has had cold-weathercamp experience, or training in risk assessment and safety when workingoutdoors in extreme weather conditions. And the US Antarctic Program has its own procedures (and harsherconditions) for outdoor safety. Soanyone doing field work is required to take “Snowcraft I” training,colloquially called “Happy Camper,” before being cleared for fielddeployments.

While the Icebreaker team all reached McMurdo Station byJanuary 7, our instruments and equipment were still in Christchurch, due to thesame flight backlog that delayed our deployment south. So we hurried to take the January 8-9class while waiting for our project gear to arrive (it showed up onSaturday).

We started with two hours of classroom instruction… risk assessment, clothing choices,weather hazards, and recognizing hypothermia and frostbite symptoms. Then we packed our sleep kits, food, tents,and stoves and headed out on to the Ross Ice Shelf. Wearing our parkas, sunglasses (to avoid snow blindness) andsnow boots. We had lunch at the“I-Hut” and hands-on instruction in camp stove lighting and maintenance. Then grabbed our bags and trudged abouta kilometer away from the I-Hut to a bare expanse of snow.

View looking back at our campsite, with Mt. Erebus in the background.

There we set up camp… initially shown by our instructorshow to set up Scott expedition tents and mountaineering tents, and how to makedeadfalls in the snow to anchor guy lines. And snowcraft… cutting half-meter cubes of snow usingsaws, sledges to pull these to make a meter-high wind wall protecting ourtents. We dug out a kitchen/diningarea, complete with snow benches (foam laid on top, for comfortableseating). And how to dig grave-likesnow trenches, 1.5m deep and wide enough for a person’s sleeping bag. Then… the instructors departed to theI-Hut, and our group of 14 was on its own overnight. It was great! Mt. Erebus in the distance, snow sawing, warm cocoa… half of our group slept in snowstructures they built, including two women who built an igloo and two men whoexcavated an underground snow cavern complete with a small kitchen.

Our camp, including the snow wall (behind tents), kitchen, and dug out snow trenches (below surface). Flags mark trenches and hazards.

The next morning, we took down our camp and were ready forthe 8:30am return of our instructors. We went back to the I-Hut and studied VHF and HF radio operations andprotocols, the contents of survival bags, and ran a couple of emergencyscenarios (my favorite was the white-out search and rescue scenario, when anyone going out had to be ropedand wear a white bucket over their head).

8-9 January 2013 Snowcraft I, “Happy Camper” field safety training class group.