Perhaps it’s a Midwestern thing, I don’t know. I grew up outside Chicago (although my family is mostly all from back east) so that’s where my theory originates regarding it being a Midwestern thing. After all, when I was growing up, nobody around me seem to think that it was odd so my assumption is that they all – we all – pronounced it this same way: “new-que-lar.” It was only later, when removed from the wayward influences of my isolated rustic upbringing was it pointed out to me – sometimes amidst unsuppressed laughter – that the word is spelled “n-u-c-l-e-a-r”. Or, in other words, it is pronounced: “new-clear.” Okay, so, whatever.

If I’m talking about ‘nuclear this’ or ‘nuclear that,’ what’s shown in the picture above is probably what popped into your head. And that’s fair. This is the way that nuclear power most commonly impacts our daily existence, i.e., through the light switches and electrical outlets in our houses that are ultimately traceable back to a power plant, some of which are based on nuclear fission reactors. Below are a couple of other applications of nuclear power with which we are familiar.

If I’m talking about ‘nuclear this’ or ‘nuclear that,’ what’s shown in the picture above is probably what popped into your head. And that’s fair. This is the way that nuclear power most commonly impacts our daily existence, i.e., through the light switches and electrical outlets in our houses that are ultimately traceable back to a power plant, some of which are based on nuclear fission reactors. Below are a couple of other applications of nuclear power with which we are familiar.

Okay, so what does this have to do with rockets? Well, there are ways to use nuclear power to create rocket propulsion. And, by the way, this is not some newfangled idea out of the blue. Did you know that one of the original plans for the third stage of what would become the Saturn V rocket was for that stage to use nuclear-thermal propulsion? That plan was eventually dropped and a configuration using a J-2 engine was chosen instead, but going all of the way back to the late 1950’s people were thinking of ways to use the extraordinary power of nuclear fission to enable and enhance space exploration.

Okay, so what does this have to do with rockets? Well, there are ways to use nuclear power to create rocket propulsion. And, by the way, this is not some newfangled idea out of the blue. Did you know that one of the original plans for the third stage of what would become the Saturn V rocket was for that stage to use nuclear-thermal propulsion? That plan was eventually dropped and a configuration using a J-2 engine was chosen instead, but going all of the way back to the late 1950’s people were thinking of ways to use the extraordinary power of nuclear fission to enable and enhance space exploration.

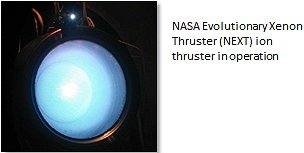

There are two basic classes of rockets that use nuclear fission. One is called “nuclear-electric” and the other is called “nuclear-thermal.” In a nuclear-electric rocket, you use the reactor to generate electricity (like a small power plant) and then use that electricity to make high-velocity ions. The latter portion of the sequence is called “ion propulsion” and there are different schemes and ideas out there, some of which have been used on unmanned spacecraft in the past using other sources for electrical power.

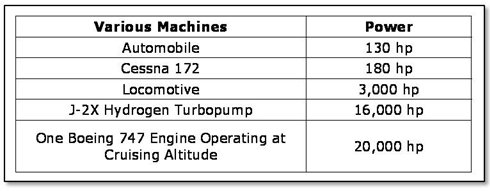

Nuclear-electric propulsion is extremely efficient. In the past we’ve talked about specific impulse being a measure of rocket efficiency. Well, a nuclear-electric propulsion system is on the order of ten or twenty times more efficient than your typical high-performance liquid hydrogen / liquid oxygen chemical propulsion rocket such as J-2X or RS-25. BUT (and this is a really, really big “but”), for all that efficiency, they don’t generate much thrust. AND they are very heavy. Thus, the only place where using nuclear-electric propulsion makes any sense is in space. Even there in “weightless” space, the extremely low thrust-to-weight ratio means that this propulsion system is only appropriate for missions where you’re willing to be very patient and get to wherever you’re going quite slowly. That’s not really an appropriate approach for missions with humans on board.

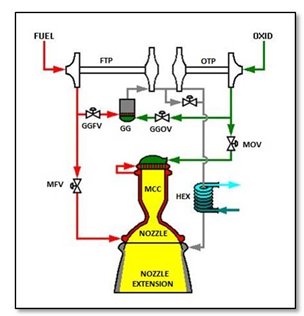

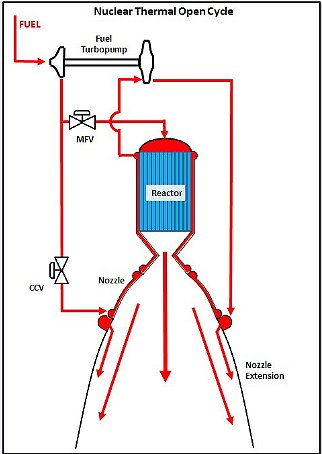

The other class of nuclear power rocket engines, and the one that I really want to tell you about, is nuclear-thermal rockets. It is appropriate that we discuss nuclear-thermal rockets in an article immediately following an article discussing expander cycle engines since they are actually closely related. Almost cousins. Below is a schematic for a nuclear-thermal rocket in the same general format as the various expander cycle engines were shown in the previous article.

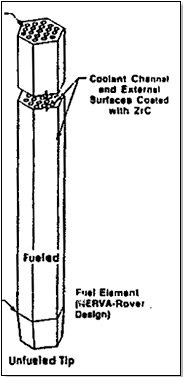

What you don’t have here is any oxidizer. Why? Because there is no combustion. In a normal rocket engine we use fuel and oxidizer in a chemical reaction to create hot combustion products. It is the ejection of those hot combustion products generate the engine thrust. For a nuclear-thermal rocket engine we use the reactor to make the hot stuff. You can think of the reactor, when operating, as a really, really powerful heat source, even more powerful than a chemical reaction. Thus, I can use that heat source to generate turbine drive gas, just as in an expander cycle engine, and I can also use that heat source to make the hot gas that generates the engine thrust. In terms of configuration, the reactor has built into it flow passages where the fuel picks up heat as it goes along. These passages can be along the outside, which I’ve shown here as feeding the turbine, and they are throughout the innards of the core. There are different ways of accomplishing this. One way is to make extrude the core rods with passages – “coolant channels” – through the length of the rods. This is shown in an old sketch from the NASA archives below. Another way to achieve this is to make the core out of pellets or “pebbles” trapped in little cages. Doing this, you’d get what’s called a “pebble-bed reactor” and such a configuration provides for lots and lots of heat exchange surface area between the core pellets and the working fluid flowing through.

So, what’s the “fuel” in the rocket schematic, i.e., the working fluid shown in red? The typical answer is hydrogen. One of the reasons that we use hydrogen in a chemical engine is because when we run fuel-rich, we get lots of hot, unreacted hydrogen as part of the exhaust. Hydrogen is very light. When it gets hot and energetic – and hydrogen picks up heat wonderfully – it moves very fast. If you think back to the rocket equation, fast moving exhaust means high performance. In this case for the nuclear-thermal rocket, the exhaust is pure hydrogen, so performance can be quite high. How high? Well, it’s not as high as the nuclear-electric options discussed above, but specific impulse values two times that of J-2X or RS-25 are entirely plausible. Further, despite the fact that nuclear-thermal engines are quite heavy, their thrust-to-weight ratio is generally much better than the nuclear-electric options. In other words, a nuclear-thermal engine has some good “oomph,” enough oomph to make it potentially usable for human spaceflight. And that’s why it was seriously contemplated in the earliest planning for the mission to the moon over fifty years ago. That’s also why, in my humble opinion, it is a prime candidate for any future human mission to Mars.

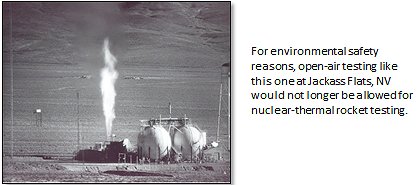

As mention above, this is not a new idea. It reaches all of the way back to the 1950’s. There was a series of active programs all throughout the 1960’s falling under the general heading of NERVA, Nuclear Engine for Rocket Vehicle Application. Below is a picture of an actual test of one of these engines.

So, with all this history behind us and with all this potential for performance, why on earth haven’t we been pursuing this technology first and foremost? Because, well, nothing is free and nothing is ever as easy as it seems at first.

The biggest struggle with nuclear-thermal rockets is that whole radiation thing. Okay, yes, I said it. Radiation is bad. Deadly. And very long-lasting. While rocket engines of any type always pack a punch in terms of power density and, therefore, the possibility for catastrophe, with the added spice of radiation, you’ve got quite the potential for a noxious stew. Does this mean that we ought to simply avoid it altogether? That’s a valid question and one that’s been debated for about 50 years. It would be presumptuous of me to suggest that I could resolve the issue definitively, but we can discuss the constituent elements rather than just falling back on the “radiation is scary” answer.

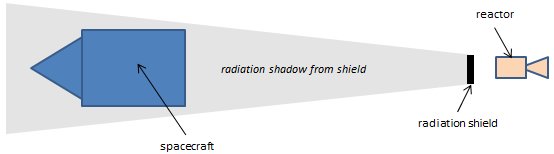

First, let’s talk about whether it could be used on a vehicle. The reactor is going to generate radiation. Internally, that’s how it works and that radiation in different forms overflows the boundaries of the reactor. It just does. So, what do you do? Well, you provide shielding. The truth is that space is chock full of radiation. If not for our little pocket of safety thanks to the magnetic poles of planet earth, we’d be cooked to the crisp by the radiation pouring out of the sun. When you’re in space, particularly if you’re going beyond our little planetary pocket of safety and traveling to the moon or to Mars, you’re going to get bombarded by radiation so no matter what, shielding is necessary. Shielding is heavy because in order for it to be effective, you need big, heavy molecules to catch gamma rays (my very simplistic explanation). Lead and tungsten are two common shielding materials for this purpose. With a fission reactor, you are also going need something for neutron flux moderation. The typical material for this is Lithium Hydride but the propellant tank itself containing hydrogen also works well for this.

A means for minimizing the weight impact for the shielding used to protect the astronauts from the reactor radiation is to use the notion of a shadow. In the sketch below, you have a reactor on the back end of the vehicle, a shield in between, and the spacecraft up front. Between, connecting everything and not shown, would be the propellant tank and the usual shiny structural trusses. As you can see, the shielding creates a shadow from the radiation within which the spacecraft sits. Now, it’s not always this simple because you sometimes need holes through the shield for functional reasons or you could get reflected/scattered radiation effects from structural elements, but this is the most common general scheme for dealing with a reactor on a spacecraft. Stick the reactor out a ways from everything, place the shield close, and cast a long, broad shadow.

Okay, you say, you’ve protected the astronauts, great. But what about the six or seven billion people back here on planet earth? After all, in order to fire up a nuclear-thermal rocket in space you first have to get it into space and that means that you have to launch it from the surface of the planet. Launch always involves risk. What happens if the launch vehicle blows up? If the launch vehicle blows up, then the reactor blows up. Wow. Now, how dangerous is that? I will not pretend that I can answer that question with my limited background. But I can tell you that prior to and during launch, the reactor is “cold.” While you probably wouldn’t want to use enriched uranium to make wallpaper for your house, it’s not that horrifically dangerous prior to use in an active reactor. It is only after the reactor gets going that the innards get all juiced up and seriously radioactive. The plan would be to launch the reactor never having been “juiced up” and only start it when it is at a safe distance from earth thereby eliminating as much as possible the potential of reentry of a hot, radioactive reactor into the atmosphere.

[Note that the fact that you need something like tungsten for a shield (very heavy metal) and you’ve got bundled up uranium in your reactor (another even heavier metal) are big reason as to why a nuclear-thermal rocket engine is typically so heavy as compared to a chemical rocket engine.]

The next issue to deal with for a nuclear-thermal rocket is probably one of the most difficult: testing. On the one hand, we’ve got lots of places where we can test rockets. On the other hand, we have certain places where we test reactors (mostly under the expert supervision of the Department of Energy in coordination with the U.S. Navy). But putting those two pieces together and playing with them as a unit, now that’s really tough. Why? Because of that darn radiation thing again.

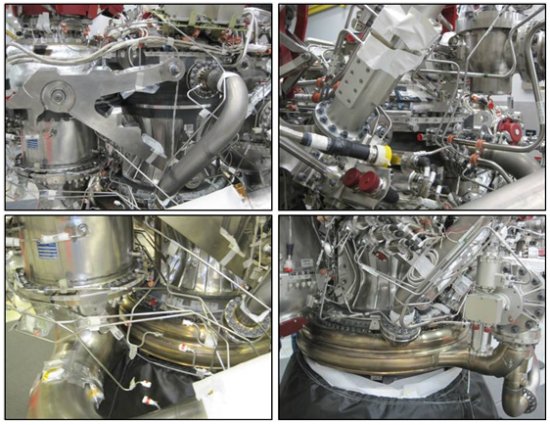

After a typical J-2X or RS-25 test, after we’ve cleared residual propellants and bled away any excessive pressures, we’ve got technicians all over those engines. They’re inspecting this, examining that, taking things apart, putting them back together. The whole point of a development program is to get data and a lot of that data comes in the form of post-test inspections. With a nuclear-thermal rocket, that wouldn’t be possible unless you really, really didn’t like your techs (please note that’s not serious, just a joke in poor taste). Once the reactor has been fired up, it’s hot. Yes, you can dial it back down so that it’s no longer at fully throttle, but both it and the surrounding stuff are contaminated to some extent with radiation. And you don’t just wipe radioactivity away with a damp rag. After that first initiation of self-sustaining chain reaction (i.e., “critical”), everything needs to be handled very differently. Also, in addition to this, the hydrogen working fluid that we push through the reactor, it too picks up some level of radiation. No, not a lot. But under modern safety restrictions, all of that hydrogen would have to be captured and scrubbed clean before release. Capturing rocket exhaust is not an easy job. It’s possible but it requires some extraordinary test facility capabilities.

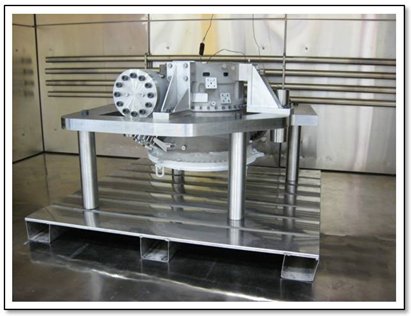

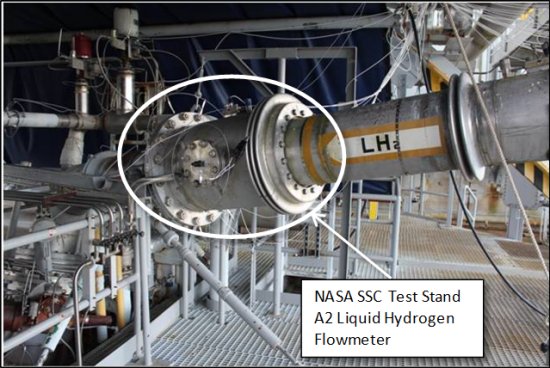

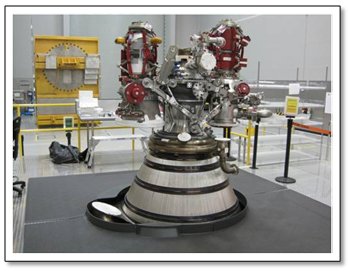

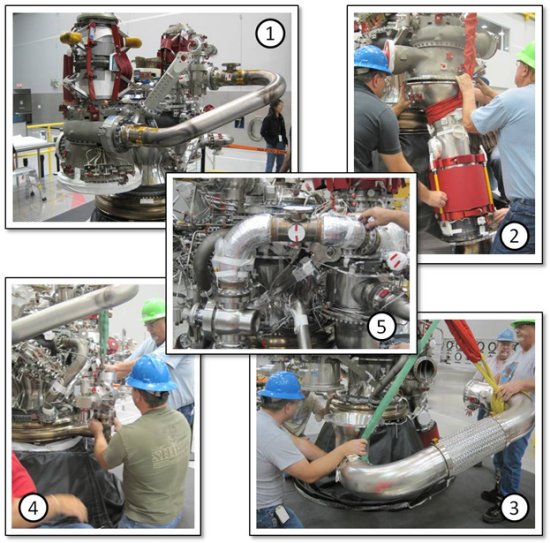

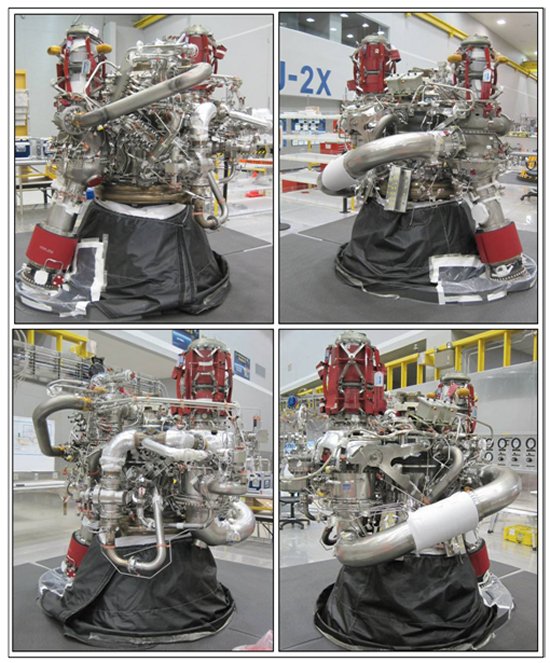

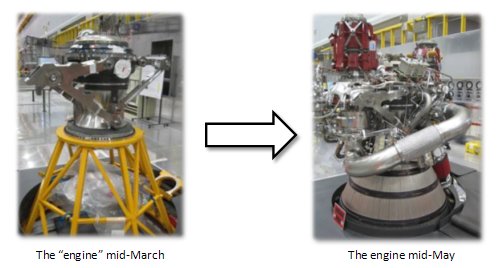

With all this difficulty, how can we conceive of getting through a development program? A rocket engine development program requires testing because, frankly, we are demonstrably not smart enough to do without it. One answer: Split the engine into two pieces. If you do the rocket part separate from the reactor part, then you can keep the two pieces blissfully in their natural environments, i.e., the rocket part on NASA test stands and the reactor part in the Department of Energy labs. Focusing on the rocket side (not surprising for me, eh?), the difficulty then becomes in simulating the heat source that is the reactor. There has been some work done here at NASA MSFC at creating reactor simulators specifically for the purpose of testing subsystem separate from reactors whether those subsystems are rocket engines or power generation systems. Below is a picture of one such reactor simulator.

In this manner you can minimize or possibly even eliminate for the combined rocket/reactor testing that is so difficult to pull off.

Before nuclear-thermal rockets can be used on missions of the future, there are a number of challenges to overcome, but the potential gains in vehicle and mission performance are impressive. While this topic doesn’t fall entirely within the realm of liquid rocket engines consistent with the title of this blog, I thought that the similarity of the schematic to expander cycle engines would be of interest. In this case, rather than a chemical reaction, you have nuclear fission, yet the engine cycle is still a matter of driving a fluid into a place where it gets hot and, from there, is ejected at high velocities. In this way, a rocket is a rocket is a rocket, even if it is “nu-que-lar.”

First, we have our Element Manager, Mike Kynard. He is a graduate of the University of Alabama [Roll Tide!], grew up not far from Tuscaloosa, and, to put it mildly, is a devoted fan of Crimson Tide football. He started working at NASA MSFC as a co-op in college back and accepted a full-time job in 1985. He spent a good spell supporting SSME from the resident office at NASA Stennis Space Center in Mississippi in the 1990s and eventually rose to become the deputy project manager for SSME back in 2004. He has two beautiful little girls and, in addition to everything else, somehow finds the time to play on a team with me in a billiards league. Sometimes, on rare occasions such as a blue moon, he even manages to beat me in a game of 8-ball.

First, we have our Element Manager, Mike Kynard. He is a graduate of the University of Alabama [Roll Tide!], grew up not far from Tuscaloosa, and, to put it mildly, is a devoted fan of Crimson Tide football. He started working at NASA MSFC as a co-op in college back and accepted a full-time job in 1985. He spent a good spell supporting SSME from the resident office at NASA Stennis Space Center in Mississippi in the 1990s and eventually rose to become the deputy project manager for SSME back in 2004. He has two beautiful little girls and, in addition to everything else, somehow finds the time to play on a team with me in a billiards league. Sometimes, on rare occasions such as a blue moon, he even manages to beat me in a game of 8-ball. Mike’s deputy is Tom Byrd. He is a graduate of Memphis State University who, once upon a time long, long ago was a competitive bicyclist. He started working here at NASA MSFC in 1983 in the area of valves and actuators, specifically supporting SSME (yes, you’ll see SSME as a recurring theme both here and when later tell you about the subsystem managers). Along the way since then, he was a subsystem manager for the Fastrac engine development effort (a NASA MSFC in-house project), was the NASA chief engineer for COBRA engine development effort, and he supported the Shuttle program in the area of systems engineering and integration. Plus, back in 1994, representing the NASA engineering community, he spent a total of four weeks in Russia studying their space transportation technologies. Tom has one young son who, given the uncanny resemblance, we suspect might be the product of a direct cloning experiment … but we don’t talk about that too much.

Mike’s deputy is Tom Byrd. He is a graduate of Memphis State University who, once upon a time long, long ago was a competitive bicyclist. He started working here at NASA MSFC in 1983 in the area of valves and actuators, specifically supporting SSME (yes, you’ll see SSME as a recurring theme both here and when later tell you about the subsystem managers). Along the way since then, he was a subsystem manager for the Fastrac engine development effort (a NASA MSFC in-house project), was the NASA chief engineer for COBRA engine development effort, and he supported the Shuttle program in the area of systems engineering and integration. Plus, back in 1994, representing the NASA engineering community, he spent a total of four weeks in Russia studying their space transportation technologies. Tom has one young son who, given the uncanny resemblance, we suspect might be the product of a direct cloning experiment … but we don’t talk about that too much. Our Chief Engineer is Eric Tepool. His job is to function as the balance point between technical and programmatic aspects of engine development. He also indirectly functions as a balance in another way, relative to our element manager’s tendencies, in that he is a graduate of Auburn University [War Eagle!]. After making his mark as a star high school athlete, just as his father was a star high school and collegiate athlete, Eric turned down athletic scholarship offers to settle into the pursuit of engineering. He started at NASA in 1990 in the turbomachinery branch, supported development and certification of the two new turbopumps for the Block 2 SSME configuration, moved on to be a subsystem manager for the COBRA engine development effort, resident manager for the Fastrac project, and the NASA-side lead systems engineer for the Integrated Powerhead Demonstrator project. He has two kids currently in college (one at Alabama, one at Auburn … yikes!) and one soon to be on her way to college.

Our Chief Engineer is Eric Tepool. His job is to function as the balance point between technical and programmatic aspects of engine development. He also indirectly functions as a balance in another way, relative to our element manager’s tendencies, in that he is a graduate of Auburn University [War Eagle!]. After making his mark as a star high school athlete, just as his father was a star high school and collegiate athlete, Eric turned down athletic scholarship offers to settle into the pursuit of engineering. He started at NASA in 1990 in the turbomachinery branch, supported development and certification of the two new turbopumps for the Block 2 SSME configuration, moved on to be a subsystem manager for the COBRA engine development effort, resident manager for the Fastrac project, and the NASA-side lead systems engineer for the Integrated Powerhead Demonstrator project. He has two kids currently in college (one at Alabama, one at Auburn … yikes!) and one soon to be on her way to college. The other “technical balance point,” in accordance with the NASA governance model, is our Chief Safety Officer Phil Boswell. He’s been working here at NASA MSFC since 1985. He started right after graduating from the University of Alabama at Birmingham (UAB). While he started in the Safety and Mission Assurance Directorate, and he’s back there now, in the interim he spent many years working within the Engineering Directorate on such projects as microgravity experiments for Shuttle and the MIR space station, the Orbital Space Plane program, and just about every propulsion element of the Shuttle itself including engines, tanks, and boosters. Phil played on the college tennis team, plays tennis still, and is an excellent golfer. His son, who will be attending UAB starting in the autumn (pre-med) follows in his father’s footsteps and is also an excellent golfer. Little known fact about Phil: he loves swing dancing and even took a year of lessons with his wife.

The other “technical balance point,” in accordance with the NASA governance model, is our Chief Safety Officer Phil Boswell. He’s been working here at NASA MSFC since 1985. He started right after graduating from the University of Alabama at Birmingham (UAB). While he started in the Safety and Mission Assurance Directorate, and he’s back there now, in the interim he spent many years working within the Engineering Directorate on such projects as microgravity experiments for Shuttle and the MIR space station, the Orbital Space Plane program, and just about every propulsion element of the Shuttle itself including engines, tanks, and boosters. Phil played on the college tennis team, plays tennis still, and is an excellent golfer. His son, who will be attending UAB starting in the autumn (pre-med) follows in his father’s footsteps and is also an excellent golfer. Little known fact about Phil: he loves swing dancing and even took a year of lessons with his wife.