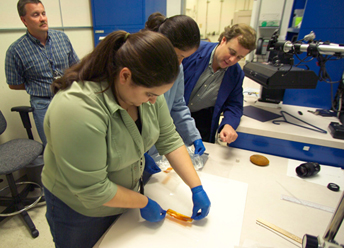

When we interviewed materials engineer Victoria (Torey) Long for  the Failure Prevention module, she described the job that she and her teammates do in the failure analysis lab as NASA’s version of detective work. In their interviews, Long and materials engineer Clara Wright both mentioned something about their childhoods

the Failure Prevention module, she described the job that she and her teammates do in the failure analysis lab as NASA’s version of detective work. In their interviews, Long and materials engineer Clara Wright both mentioned something about their childhoods

that probably made them natural-born failure analysts. Long’s pastime was reading Nancy Drew mysteries. Wright liked to construct jigsaw puzzles.

If you have students who enjoy solving problems and mysteries, they probably will enjoy creating a multimedia project with the Failure Prevention module. They may also like reading the article CSI: NASA. It is about the failure analysis lab at Kennedy Space Center.

The lab, nicknamed “Malfunction Junction,” is the place where

mysteries are solved. The article intimates that the failure

analysis team is similar to TV’s crime investigators. They investigate

mishaps with rocket hardware. If something goes wrong with a launch, this is the team to call.

The article also gives hints about the type of personalities that are better suited for this kind of work. Who knows? A future engineer or failure analyst may be sitting in your classroom who never knew that this career choice is an option.

DIY Podcast: Failure Prevention

Please Note: If you leave a comment, do not include a link to your blog or other websites. We typically won’t be able to approve your comment if you add a URL.