Much has been said recently regarding the cost and schedule related to NASA’s successor program to the Space Shuttle. However, this is a subject where considerably more heat than light has been generated, so let’s review the bidding as objectively as possible.

First, some facts: NASA’s commitment has been and continues to be to achieve the first human launch of Orion by March 2015. We see that as eminently achievable, but it’s not a guarantee – there is no such thing in any large scale development program and especially for one where the available funding is never known more than one year in advance.

While there has been moderate growth relative to early cost estimates, these increases are contained within the projected budget profile to which the agency has worked to for the last three years. The development cost for achieving the first crewed flight today is roughly $30 billion, far short of estimates which have been recently bandied about.

How We Got Here

The Constellation Program, now in its fourth year, has nearly completed its ‘formulation’ phase – this is the phase in which concepts are developed, capabilities are defined, requirements are written, and contracts are established with industry.

When the program began, one of the many constraints it was called upon to honor was a ‘go as you pay’ plan – that is, the pace of the program would be dictated largely by the share of NASA’s annual budget that human spaceflight has historically been allocated.

Based on that constraint, it was always recognized that funding for a new development program would be exceedingly tight in the years 2008 thru 2010.

A second constraint, the key to achieving our exploration goals beyond low Earth orbit, was to make our early investments in Orion and Ares I so as to ensure that they could support missions to the moon, the near-Earth asteroids, and Mars, while nonetheless providing the capability to service the International Space Station

A third constraint embodied in legislative guidance was to use as much shuttle infrastructure and workforce as makes sense in the design of NASA’s new human spaceflight architecture.

All of this was in compliance with national policy. That policy, which was born out of the findings of the Columbia accident, started with a ‘vision’ from the Executive Branch in 2004, and then codified in two Congressional authorization acts in 2005 and 2008.

An additional desire (regrettably, never a policy mandate) was to do whatever possible to ‘close the gap’ between the last shuttle flight and the start of Constellation launches from KSC.

In short, Constellation is not ‘NASA’s plan’ – it is the manifestation of national policy.

Moreover, Orion and Ares I are not standalone products – the Constellation Program is a collection of seven product lines to conduct operations in and beyond Low Earth Orbit… servicing the ISS, returning U.S. astronauts to the Moon, and enabling exploration beyond – to Mars, Near Earth Asteroids, or other destinations in the solar system. This entire range of product lines encompasses the Constellation architecture.

So with these constraints, and many more, NASA’s Constellation team has executed this early phase – called ‘formulation’ – at historically low cost for a human spaceflight development program. Compared to Apollo, and to Shuttle, and to Space Station, Constellation has been markedly leaner in its efforts to date.

So Why Can’t Orion Fly Sooner?

As we have openly discussed, it is true that inside NASA we challenged our team during this ‘formulation’ phase of Constellation to do better than March of 2015 for flying Orion for the first time with a crew.

Our earliest plans had the first crewed mission targeted for September of 2013. While none of the cost estimates showed that date to be likely, we still felt that being internally aggressive would help us clarify what was really necessary to do the job. In that respect, as a program management strategy, it has succeeded.

It is also true that over the last year, as we approached the end of this formative period, we have adjusted our internal schedules to align with the reasonable projection of our ever-improving cost estimates.

We have thus gained a level of understanding of the ‘work to go’ that is very rich in detail, and a depth in understanding of what each of our requirements costs in time and money – perhaps as well as NASA has ever done. I will leave that to others to judge, but I’m quite proud of what we have been able to achieve.

It is simply a matter of money at this point, not technology. Further, it is not merely a matter of total cost, but also of the time-phasing of when the money becomes available.

Of ‘Unk-Unks’ and Schedules

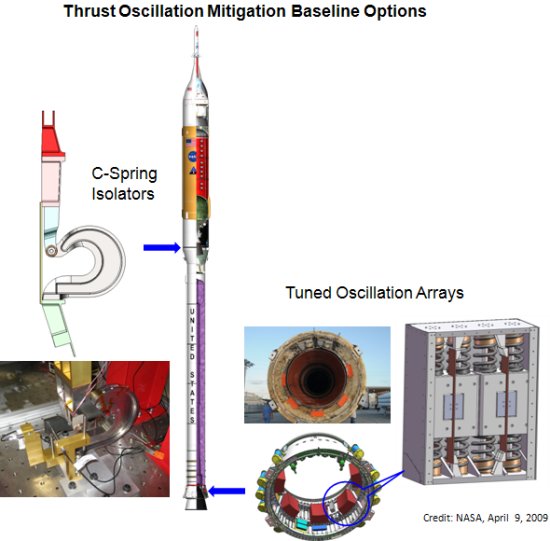

We have been asked consistently for the last three years ‘what would it take to fly as early as possible’? Study after study of that question has revealed roughly the same answer – not more money, but money earlier, is the key to flying sooner, more confidently, and ultimately with the smallest amount of delay due to ‘problems’.

This is simply because, with sufficient early funding, engineers can investigate the riskiest parts of an emerging design for a spacecraft system or a rocket component and discover hidden problems early, before the design is ‘locked down’.

We call these ‘unknown unknowns’ or unk-unks, and if discovered early they can be accounted for in the design before building the final vehicle or system.

If discovered too late, after the design is ‘locked down’, then there is considerable cost required to rework the design, while the rest of the team waits until it is fixed.

We have done as much early risk mitigation as we have been able to afford in parallel with actually doing the design. But we have been forced to defer or eliminate some of that work in order to remain within our 2009 and 2010 funding limits – which have themselves changed as a result of Administration and Congressional decisions.

So those unk-unk’s we should be discovering now are lying in wait for us, and are of concern as we formulate our plan for achieving a March 2015 first crewed Orion launch, let alone anything earlier.

Keys to Success

NASA’s plans and programs are strictly a reflection of national policy. If the policy is to ‘go to the Moon by 2020’ and ‘go as you pay’, we respond with ‘here is how we propose to do it and, as best we can gauge it, here is how much it will cost’.

A few keys to success – and they are nothing new to program and project managers in any industry – are:

· stable funding – don’t keep changing the money

· stable requirements – don’t keep changing the plan

· early investments to investigate the riskiest parts of a complex design such as a human spaceflight system will save billions in delays and overruns

· a clear vision of the desired outcome – help the team ‘see’ the end game

NASA has done what it said it would do, indeed what it has been directed to do under national policy.

We have a functioning successor program to the shuttle. It is employing and re-invigorating the NASA institution across all of its 10 centers in California, Mississippi, Virginia, Ohio, Florida, Texas, Alabama and New Mexico.

We are today producing detailed designs and preparing to perform flight testing this year from test facilities in New Mexico and a shuttle launch pad in Florida.

We have laid out a plan and architecture, not just to replace the space shuttle, but to take astronauts beyond Low Earth Orbit. Not only are the Orion spacecraft and Ares I rocket progressing well in their designs, but early concept work is proceeding on the heavy-lift Ares V rocket, which will be more powerful than Apollo’s Saturn V, and the Altair Lunar Lander.

Construction is progressing at the Kennedy Space Center on launch pads, processing facilities and even the factory where Orion will be assembled.

Large scale facilities are being renovated or built anew in Utah, California, Colorado, Ohio, Mississippi and Louisiana to fabricate and test the major components. And orders are being placed with high technology suppliers in most states of the union.

NASA’s Constellation Program is rejuvenating an agency and an industry.

NASA’s value lies in the trails that it blazes, the things we do that are hard, so that industry can follow and create new markets. Our role is to occupy the pinnacle of a $300B ‘space economy’ that generates products and services that bolster the nation’s broader economic productivity. We are doing so in a highly constrained ‘go as you pay’ environment, in parallel with meeting the nation’s commitment to completing the International Space Station, retiring the Space Shuttle, and mapping a course for human endeavor beyond our experience.

Contributed by Jeff Hanley, Constellation Program Manager

What do the patches and pins that represent NASA’s Constellation Program and its projects symbolize? Most of you have seen the crew patches, similar to the shoulder patches worn by members of the military units, that are used to identify each NASA mission.

What do the patches and pins that represent NASA’s Constellation Program and its projects symbolize? Most of you have seen the crew patches, similar to the shoulder patches worn by members of the military units, that are used to identify each NASA mission.