This week, I’d like to introduce guest blogger Jared Austin, a fellow writer on the SLS Strategic Communications team, for a peek into a part of the SLS team that is rarely seen, but creates some of our most-seen tools. — David

Few people know Barry Howell and what he’s done for the space program for decades. Neither astronaut nor engineer, through his work as a master model maker Barry has helped NASA visualize spacecraft before they existed.

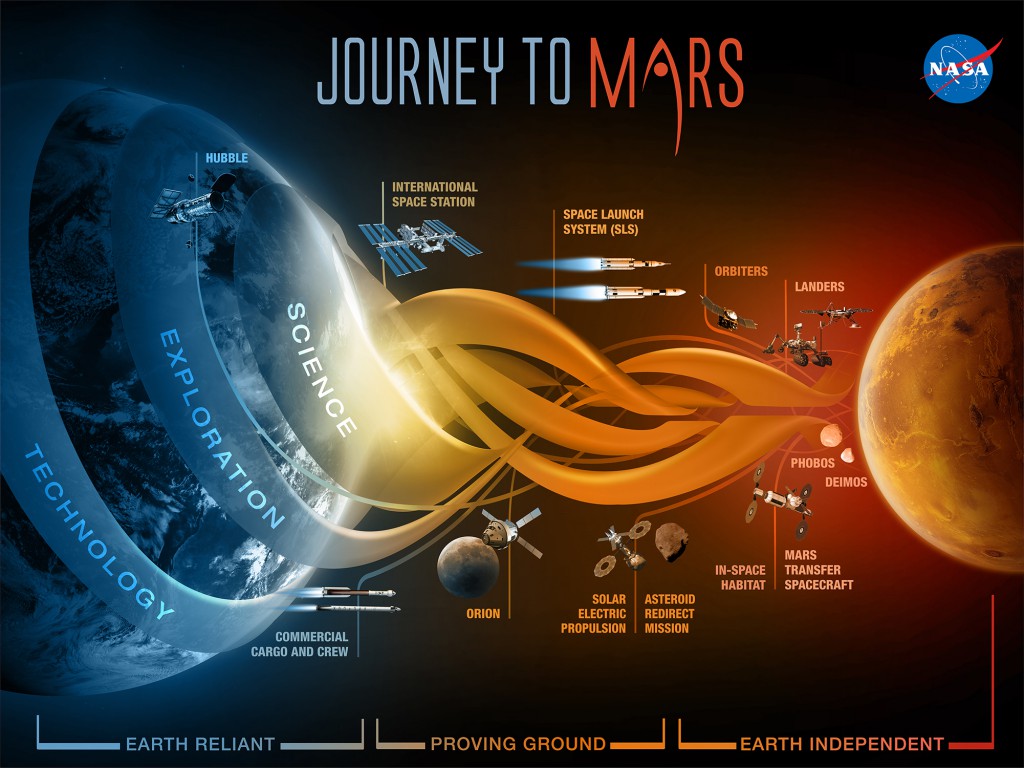

For more than 40 years, Barry’s “office” has been a space model workshop filled with the past, present and futures of NASA. Barry has created models of many of NASA’s greatest endeavors – from the mighty Saturn 1B and Saturn V, to the iconic Space Shuttle, to early concepts of the International Space Station, to the Hubble Space Telescope, and many other vehicles. Those models aren’t the mass produced, off-the-shelf toys that little Timmy or Sarah receives for their eighth birthdays. Barry’s models are works of both artistic and technical mastery that are painstakingly crafted to scale in a variety of sizes from models that will fit on your desk to a giant that is over 12 feet tall.

You don’t last forty years at a job unless you’re extremely passionate about what you do. Barry’s craft is a rare calling – there are only a small handful of modellers at Marshall Space Flight Center, and only a few NASA centers have model shops. Model makers who get a job like this tend to keep it for a long time, so turnover is low and opportunities are infrequent. Barry came to the job from a background in machining, which he started working while in high school. But when there is an opening in the model shop, there really is only one job qualification – be the best at what you do. There’s no particular education or experience requirement, unmatched skill is the determining factor.

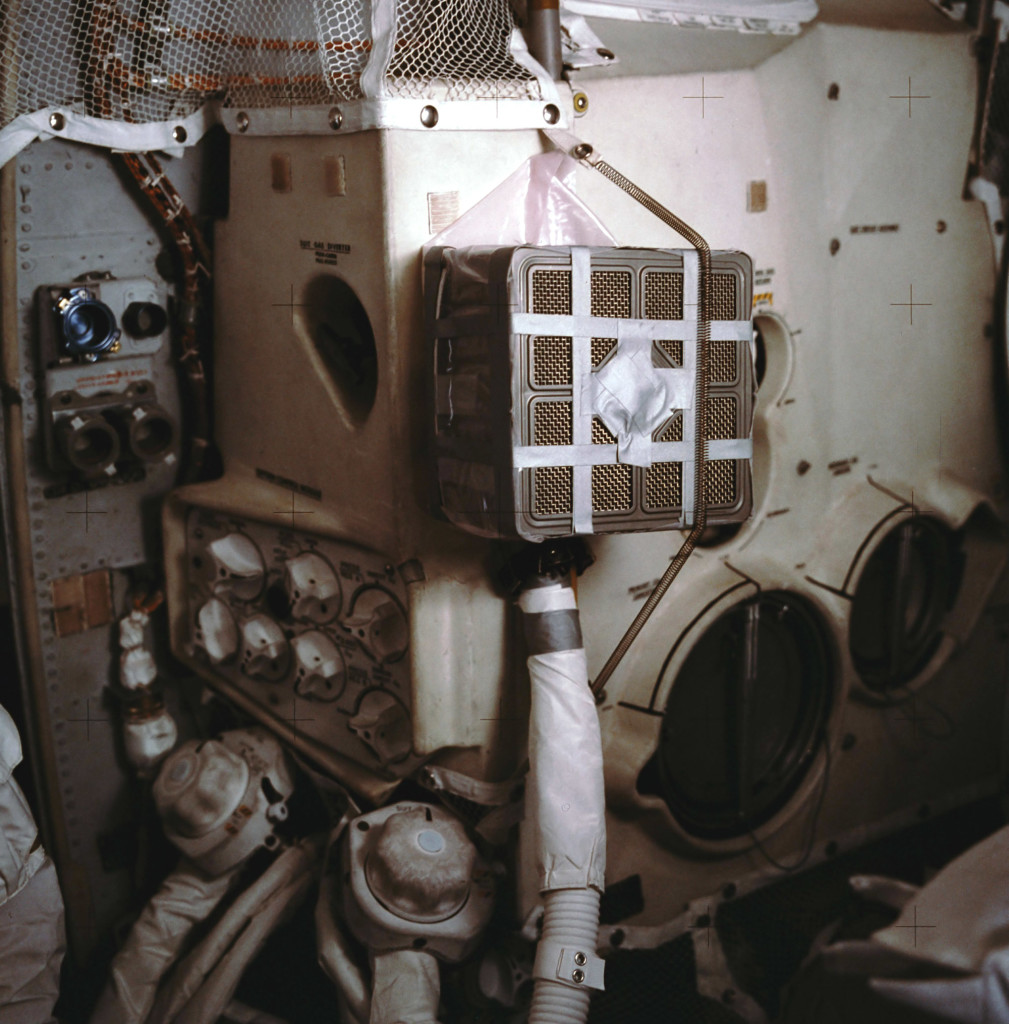

Over the course of his career, Barry’s work has helped solve the agency’s most challenging problems, letting engineers visualize the hardware they are designing and building, and to prove concepts such as the shade on Skylab. After Skylab’s launch, NASA had only 10 days to design and build a sunshade for the space station. Barry helped build a model to demonstrate that the umbrella-like shade that Marshall engineers were designing would properly shield Skylab from the sun’s heat. And his work is rather unique within NASA.

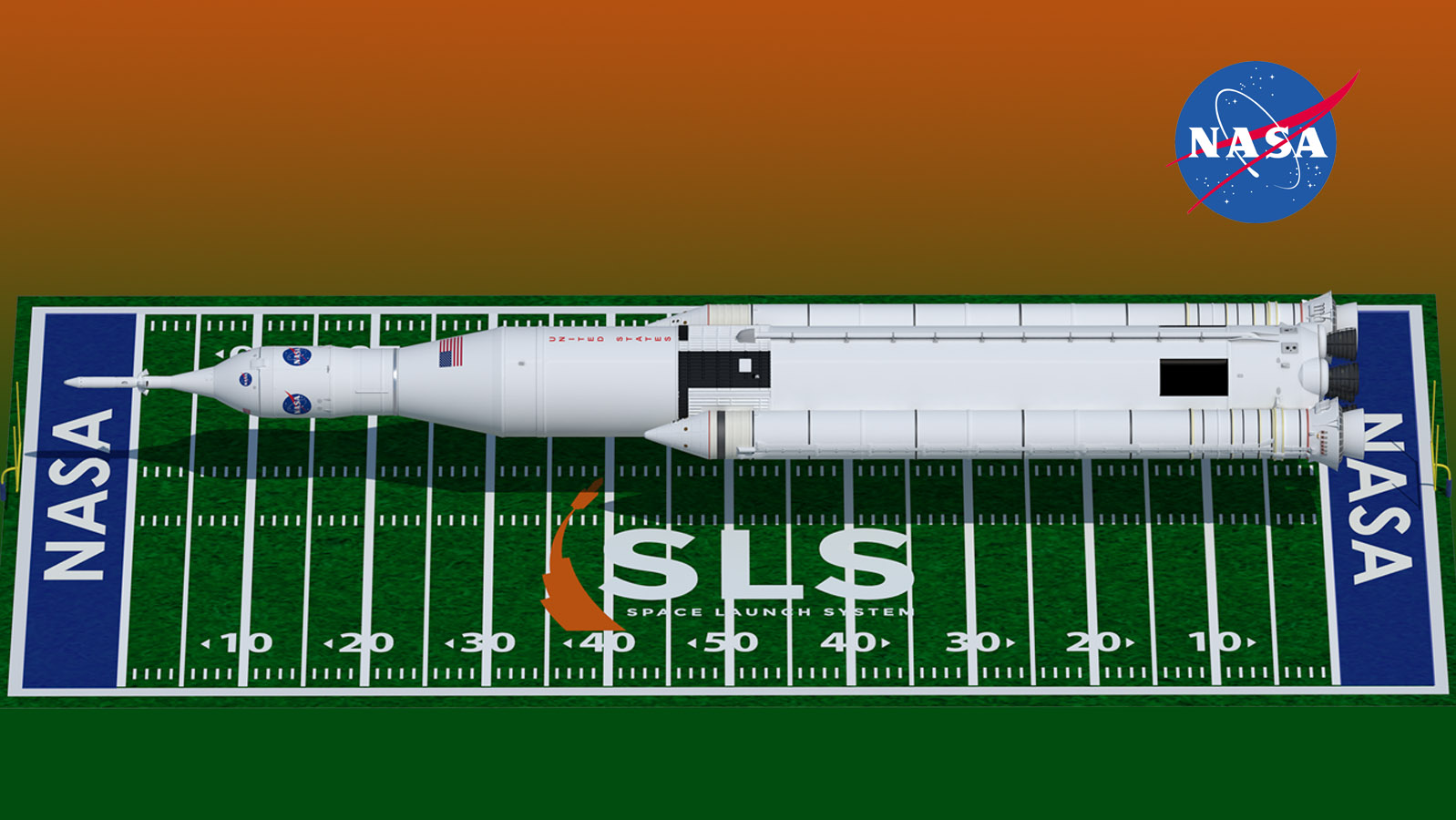

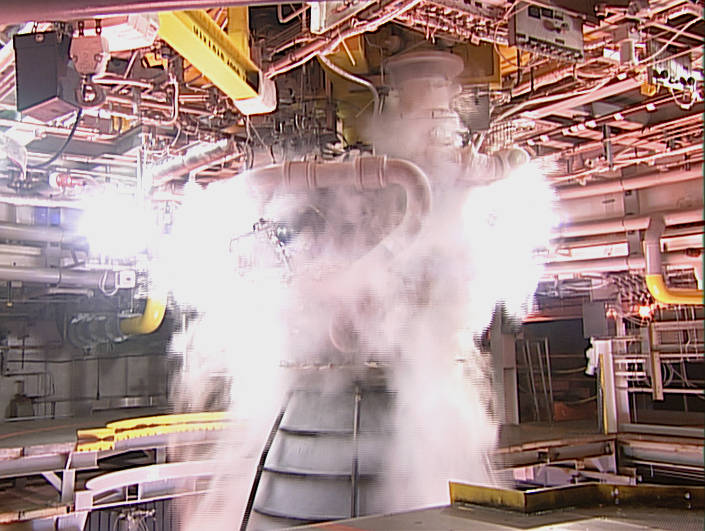

Now Barry is taking his decades of experience in modeling all types of NASA systems and using it to produce models of America’s next great rocket, the Space Launch System.

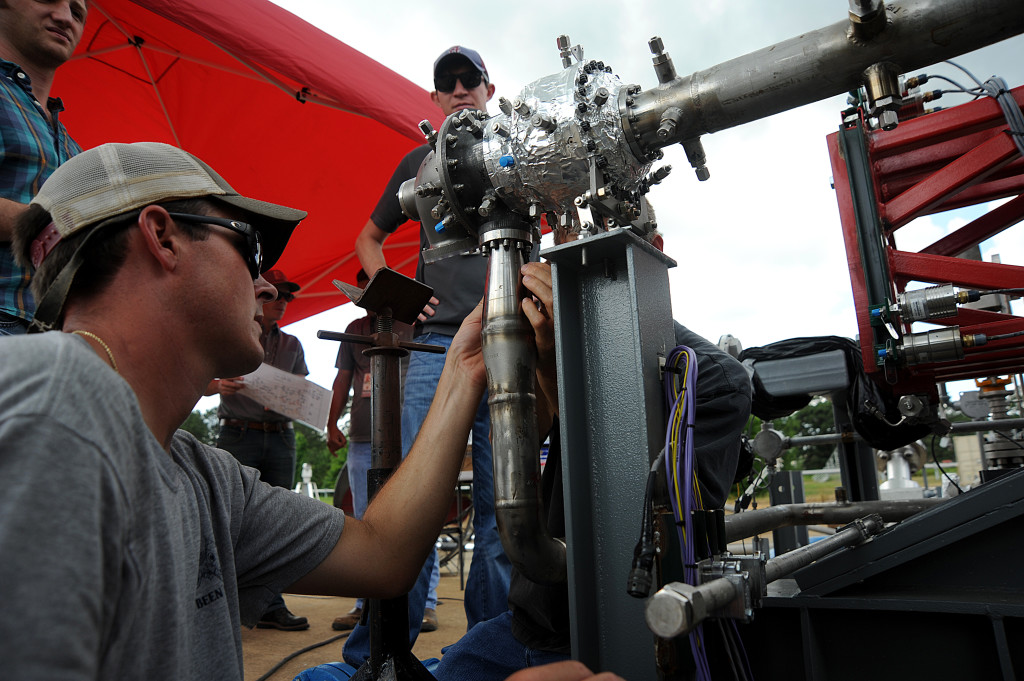

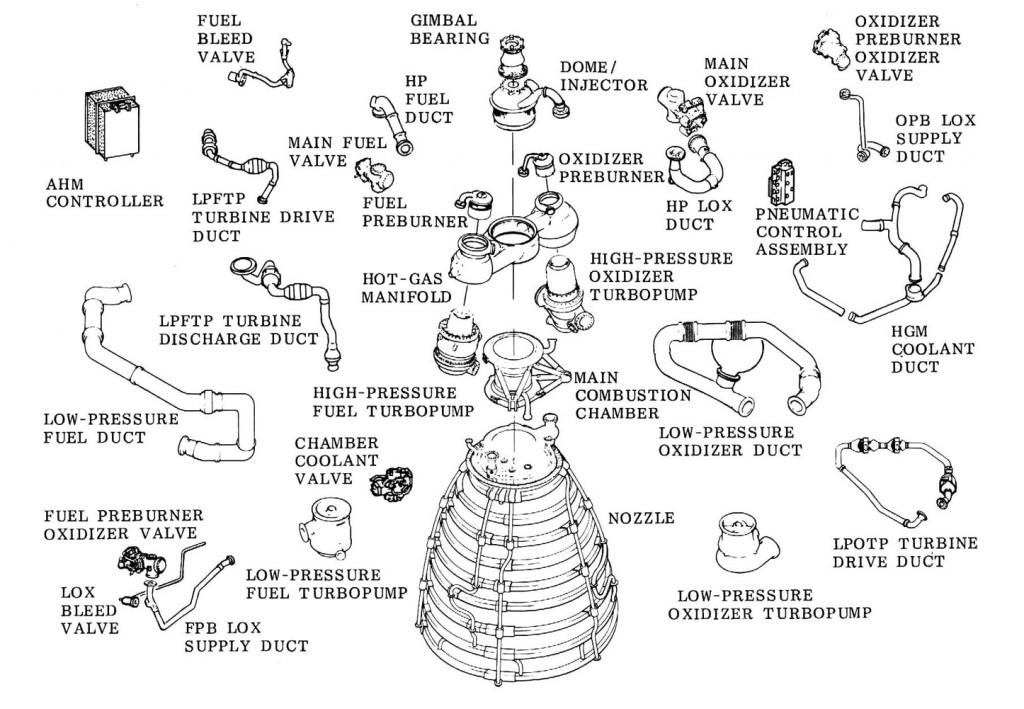

During his tenure in the model shop, Barry has seen changes in technology and process, along with classic methods that have stood the test of time. In the old days of Saturn and early Shuttle, each and every model would be carefully machined according to actual blueprints that allowed Barry to ensure they were precise representations of the real rockets. Working with aluminum or plexiglass blocks, Barry would carefully drill into blocks with a mill or strip away pieces with a lathe, using nothing more than his focused eye, steady hands, and well-honed judgment to carve the individual parts of the rocket from those blocks.

Today, for SLS, model production is a combination of old and new techniques. There’s no longer a need to individually handcraft each model that’s produced; resin casting allows for mass production of models, allowing the model shop to churn out the models at a faster rate and lower cost. But in order to produce the mold for that casting, the old ways are still best. To this day, Barry produces his initial master for each model line with the meticulous same mill and lathe machining process that he used during Saturn.

Recently, though, even more modern techniques have entered the model shop in the form of 3D printing, creating small astronaut figures, handheld models of the rocket, or small versions of the SLS engines. It’s a new area that the modelers have just begun to explore and holds many possibilities for improving the way they make SLS models going forward.

“I truly love every part of the model-making process, as well as the variety of different models that I’ve gotten the chance to make at NASA,” Barry said. “And the young guys I get to work with, they come up with a lot of great ideas on how to make things even better.

Barry has also been very gracious in passing on his knowledge to others. Modelers who create their own models at home will often request Barry’s inputs to help them make custom-made parts that look more realistic.

Now, as Barry rides off into the sunset of retirement in a couple of months, he’ll be leaving behind a legacy of models showing NASA’s greatest technological achievements. Barry has helped tell the exploration story and by capturing NASA history in 3D for decades.

Next Time: A Model Worker

Join in the conversation: Visit our Facebook page to comment on the post about this blog. We’d love to hear your feedback!