Written by Beverly Perry

What do water and aluminum have in common?

If you guessed that water and aluminum make SLS fly, give yourself a gold star!

Chemistry is at the heart of making rockets fly. Rocket propulsion follows Newton’s Third Law, which states that for every action there is an equal and opposite reaction. To get a rocket off the launch pad, create a chemical reaction that shoots gas and particles out one end of the rocket and the rocket will go the other way.

What kind of chemical reaction gets hot gases shooting out of the business end of a rocket with enough velocity to unshackle it from Earth’s gravity? Combustion.

Whether it’s your personal vehicle or a behemoth launch vehicle like SLS, the basics are the same. Combustion (burning something) releases energy, which makes things go. Start with fuel (something to burn) and an oxidizer (something to make it burn) and now you’ve got propellant. Give it a spark and energy is released, along with some byproducts.

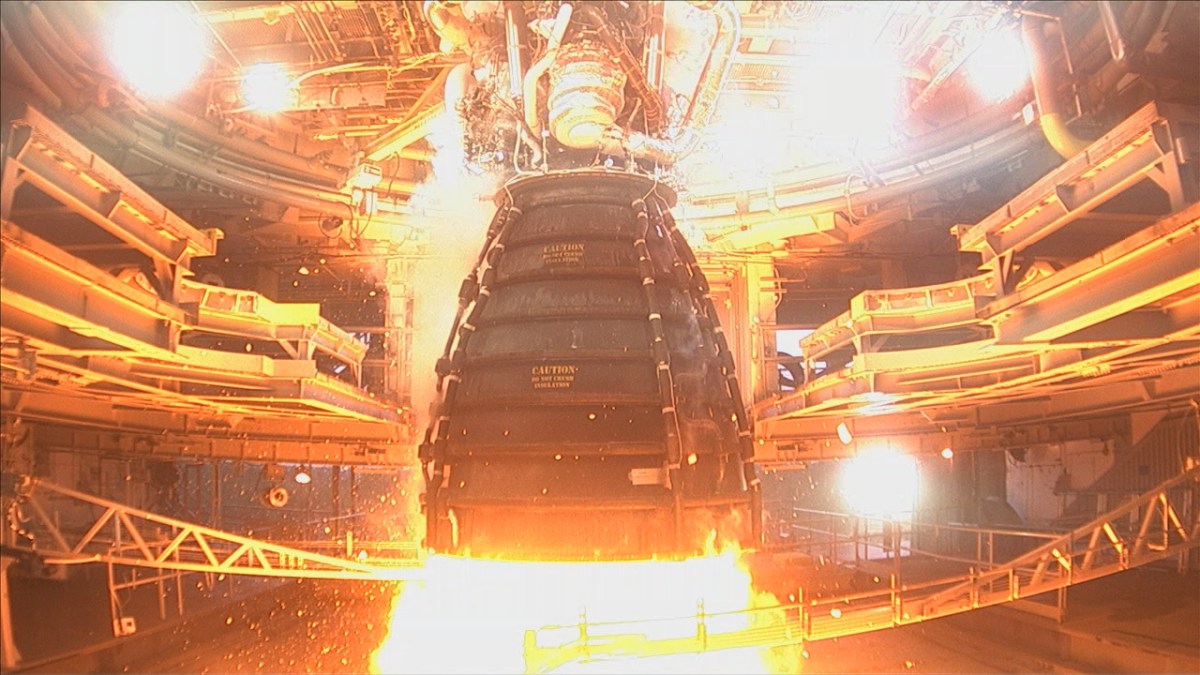

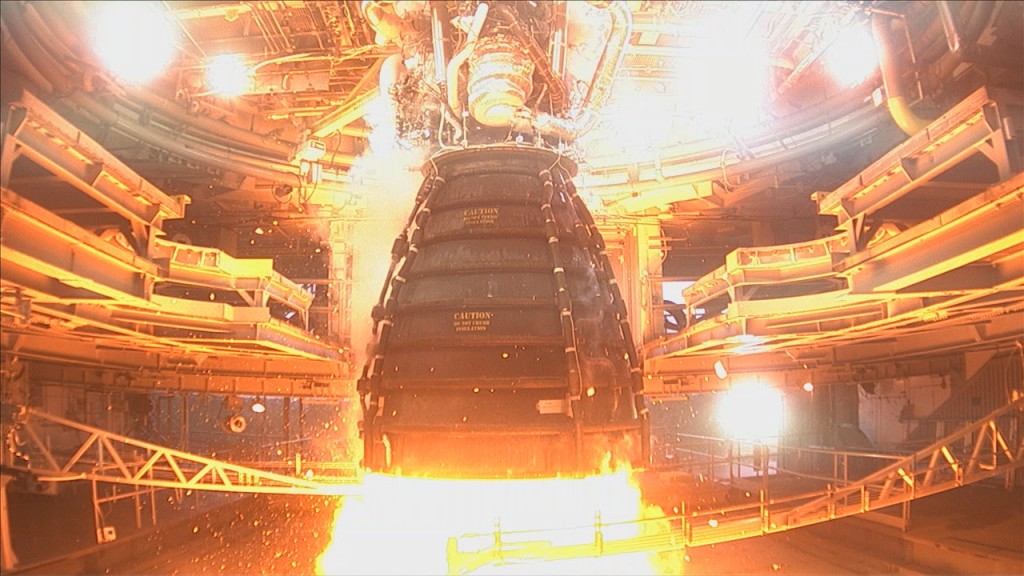

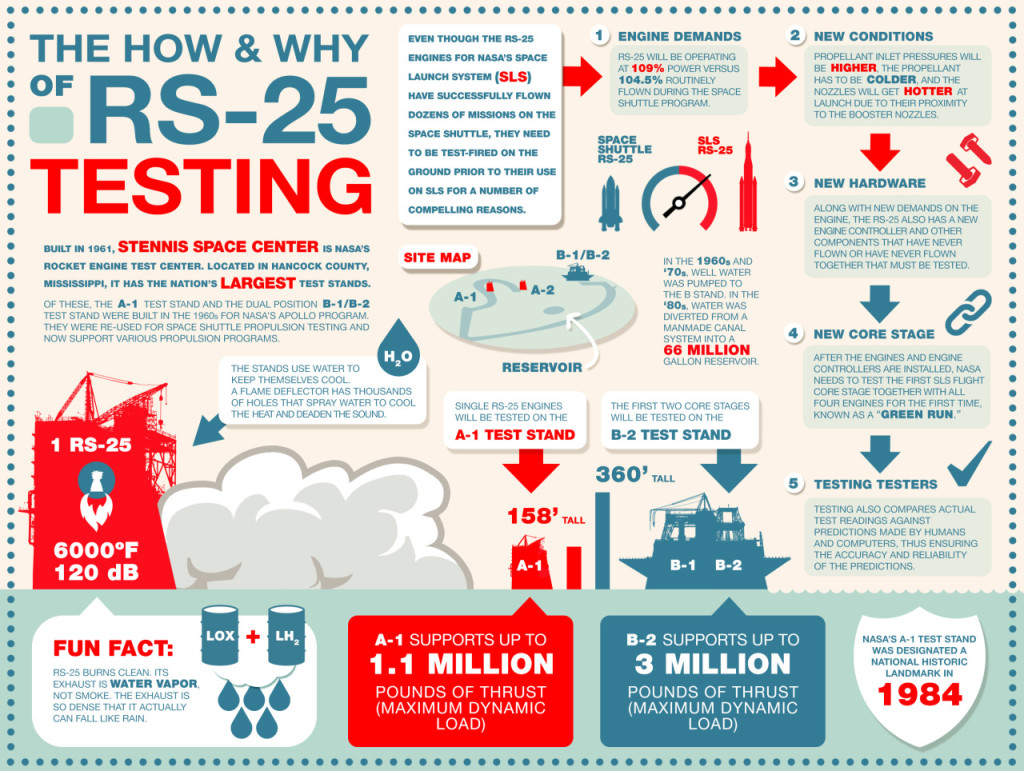

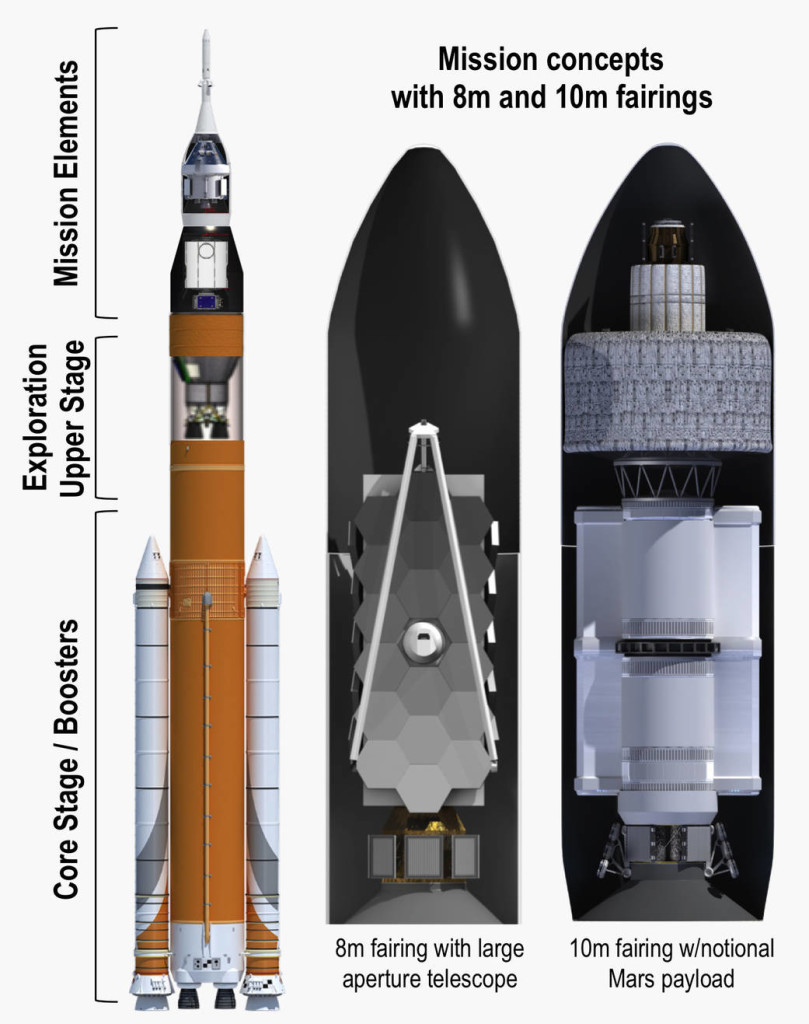

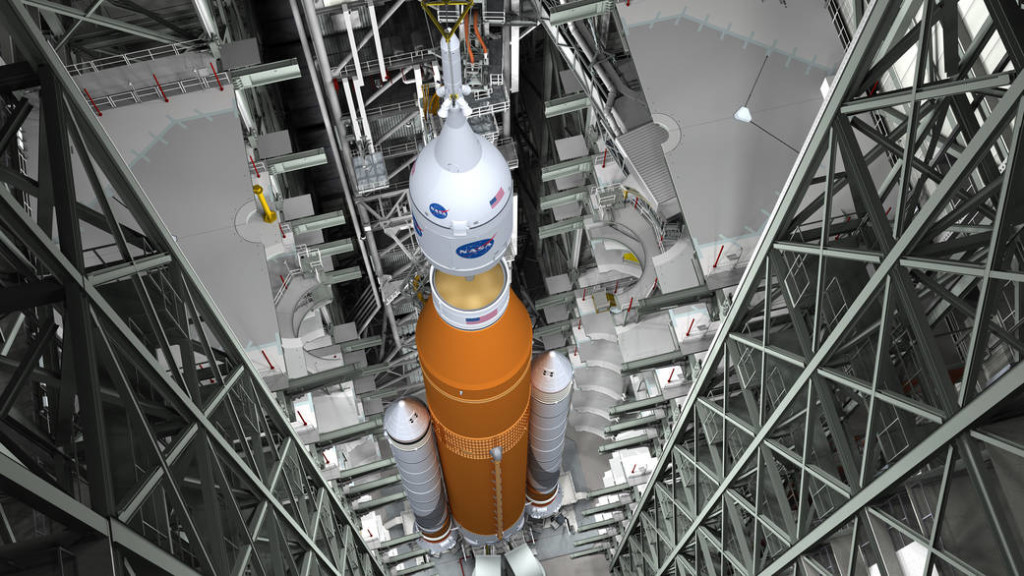

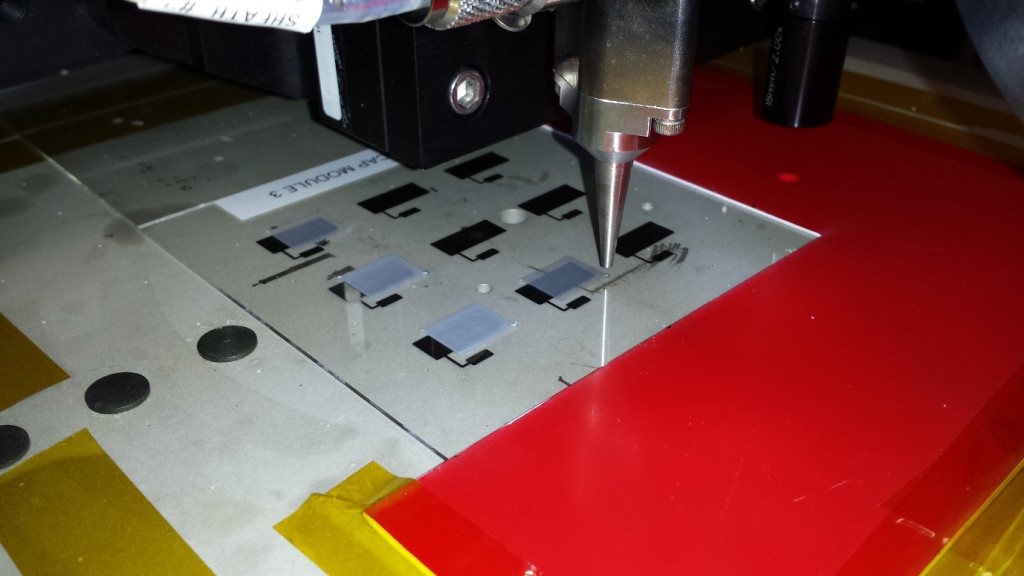

For SLS to fly, combustion takes place in two primary areas: the main engines (four Aerojet Rocketdyne RS-25s) and the twin solid rocket boosters (built by Orbital ATK) that provide more than 75 percent of thrust at liftoff. Combustion powers both propulsion systems, but the fuels and oxidizers are different.

The RS-25 main engines are called “liquid engines” because the fuel is liquid hydrogen (LH2). Liquid oxygen (LOX) serves as the oxidizer. The boosters, on the other hand, use aluminum as fuel with ammonium perchlorate as the oxidizer, mixed with a binder that creates one homogenous solid propellant.

Making water makes SLS fly

Hydrogen, the fuel for the main engines, is the lightest element and normally exists as a gas. Gases – especially lightweight hydrogen – are low-density, which means a little of it takes up a lot of space. To have enough to power a large combustion reaction would require an incredibly large tank to hold it – the opposite of what’s needed for an aerodynamically designed launch vehicle.

Hydrogen, the fuel for the main engines, is the lightest element and normally exists as a gas. Gases – especially lightweight hydrogen – are low-density, which means a little of it takes up a lot of space. To have enough to power a large combustion reaction would require an incredibly large tank to hold it – the opposite of what’s needed for an aerodynamically designed launch vehicle.

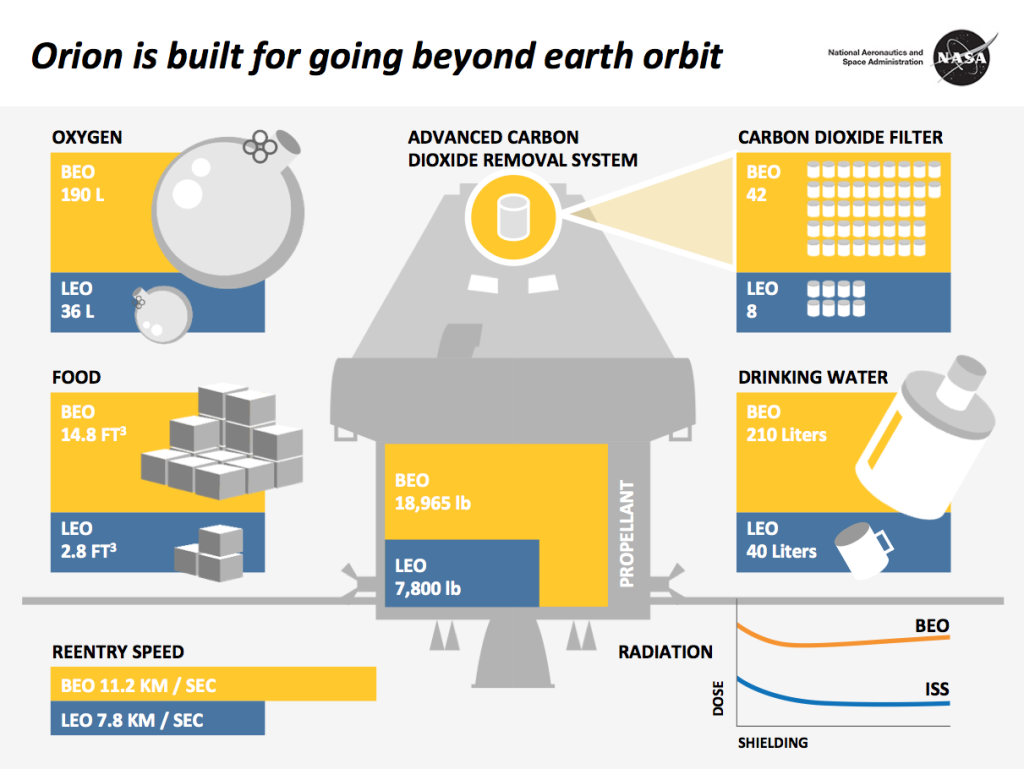

To get around this problem, turn the hydrogen gas into a liquid, which is denser than a gas. This means cooling the hydrogen to a temperature of ‑423 degrees Fahrenheit (‑253 degrees Celsius). Seriously cold.

Although it’s denser than hydrogen, oxygen also needs to be compressed into a liquid to fit in a smaller, lighter tank. To transform oxygen into its liquid state, it is cooled to a temperature of ‑297 degrees Fahrenheit (‑183 degrees Celsius). While that’s balmy compared to LH2, both propellant ingredients need special handling at these temperatures. What’s more, the cryogenic LH2 and LOX evaporate quickly at ambient pressure and temperature, meaning the rocket can’t be loaded with propellant until a few hours before launch.

Although it’s denser than hydrogen, oxygen also needs to be compressed into a liquid to fit in a smaller, lighter tank. To transform oxygen into its liquid state, it is cooled to a temperature of ‑297 degrees Fahrenheit (‑183 degrees Celsius). While that’s balmy compared to LH2, both propellant ingredients need special handling at these temperatures. What’s more, the cryogenic LH2 and LOX evaporate quickly at ambient pressure and temperature, meaning the rocket can’t be loaded with propellant until a few hours before launch.

Once in the tanks and with the launch countdown nearing zero, the LH2 and LOX are pumped into the combustion chamber of each engine. When the propellant is ignited, the hydrogen reacts explosively with oxygen to form: water! Elementary!

2H2 + O2 = 2H2O + Energy

This “green” reaction releases massive amounts of energy along with superheated water (steam). The hydrogen-oxygen reaction generates tremendous heat, causing the water vapor to expand and exit the engine nozzles at speeds of 10,000 miles per hour! All that fast-moving steam creates the thrust that propels the rocket from Earth.

It’s all about impulse

But it’s not just the environmentally friendly water reaction that makes cryogenic LH2 a fantastic rocket fuel. It’s all about impulse – specific impulse. This measure of the efficiency of rocket fuel describes the amount of thrust per amount of fuel burned. The higher the specific impulse, the more “push off the pad” you get per each pound of fuel.

The LH2-LOX propellant has the highest specific impulse of any commonly used rocket fuel, and the incredibly efficient RS-25 engine gets great gas mileage out of an already efficient fuel.

But even though LH2 has the highest specific impulse, because of its low density, carrying enough LH2 to fuel the reaction needed to leave Earth’s surface would require a tank too big, too heavy and with too much insulation protecting the cryogenic propellant to be practical.

To get around that, designers gave SLS a boost.

Next time: How the solid rocket boosters use aluminum – the same stuff you use to cover your leftovers – to provide enough thrust to get SLS off the ground.

Join in the conversation: Visit our Facebook page to comment on the post about this blog. We’d love to hear your feedback!