NASA’s Space Launch System (SLS), which will launch Orion on missions to deep space destinations like an asteroid and on toward Mars marked important steps this week to prepare for journeys beyond Earth orbit.

Engineers at the agency’s Stennis Space Center near Bay St. Louis, Mississippi, conducted a successful 450-second test of the RS-25 rocket engine May 28. The hotfire test was conducted on the historic A-1 Test Stand where Apollo Program rocket stages and Space Shuttle Program main engines also were tested. RS-25 engines tested on the stand will power the core stage of NASA’s new rocket with Orion atop it.

One of the objectives being evaluated in this test is the new engine controller, or “brain.” The RS-25 is unique among many engines in that it automatically runs through its cycles and programs. The controller monitors the engine conditions and communicates the performance needs. The performance specifications, such as what percentage of thrust is needed and when, are programmed into the controller before the engines are fired. For example, if the engine is required to cycle up to 90 percent thrust, the controller monitors the fuel mixture ratio and regulates the thrust accordingly. It is essential that the controller communicates clearly with the engine; the SLS will be bigger than previous rockets and fly unprecedented missions, and its engines will have to perform in new ways.

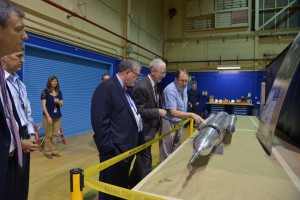

Engine maker Aerojet Rocketdyne also completed RS-25 Engine 2063 at Stennis, after approximately three months of work. The new engine becomes the 16th assembled RS-25 flight engine in inventory for SLS flights. The engine will be one of four RS-25s used to power Exploration Mission 2, the second SLS launch with Orion targeted for the 2021 time frame. Testing of these four engines will begin later this year as work accelerates on NASA’s newest launch vehicle. Four previously-flown RS-25s will be attached to the first SLS core stage and test fired together as a stage before being approved for the first SLS launch planned for 2018, the first integrated mission with Orion. Check out more, including a timelapse video of the assembly here.

NASA’s Space Launch System rocket. Orion’s team of engineers will use the mockup to verify the configuration of these vehicle components for EM-1, which ultimately saves assembly time and reduces risk. The mockup will then be connected to hardware emulations of the full EM-1 stack (Orion crew module, European Service Module, second stage booster and the Space Launch System) as well as ground support equipment. Once it’s connected, the team will simulate and test every aspect of the EM-1 mission from launch to splashdown. Orion will enable astronauts to explore new destinations in the solar system, including an asteroid and on toward Mars.

NASA’s Space Launch System rocket. Orion’s team of engineers will use the mockup to verify the configuration of these vehicle components for EM-1, which ultimately saves assembly time and reduces risk. The mockup will then be connected to hardware emulations of the full EM-1 stack (Orion crew module, European Service Module, second stage booster and the Space Launch System) as well as ground support equipment. Once it’s connected, the team will simulate and test every aspect of the EM-1 mission from launch to splashdown. Orion will enable astronauts to explore new destinations in the solar system, including an asteroid and on toward Mars.

ears since President Obama visited NASA’s Kennedy Space Center in Florida to outline his plan for America’s space program. The President’s speech took place at the Neil Armstrong Operations & Checkout Building, where since that time, Orion was processed and outfitted ahead of its first trip to space in December 2014. NASA-wide, significant progress had been made within the last five years, and the work to reach for new heights continues. Check out the progress NASA has made on our journey:

ears since President Obama visited NASA’s Kennedy Space Center in Florida to outline his plan for America’s space program. The President’s speech took place at the Neil Armstrong Operations & Checkout Building, where since that time, Orion was processed and outfitted ahead of its first trip to space in December 2014. NASA-wide, significant progress had been made within the last five years, and the work to reach for new heights continues. Check out the progress NASA has made on our journey:  A’s new Space Launch System (SLS) launches on its first flight, it will be doing some serious multi-tasking. Not only will Exploration Mission-1 test the performance of SLS and its integration with the Orion spacecraft – the agency plans to use its massive lift capability to carry nearly a dozen nano-satellites to conduct science experiments beyond low Earth orbit.

A’s new Space Launch System (SLS) launches on its first flight, it will be doing some serious multi-tasking. Not only will Exploration Mission-1 test the performance of SLS and its integration with the Orion spacecraft – the agency plans to use its massive lift capability to carry nearly a dozen nano-satellites to conduct science experiments beyond low Earth orbit. am managers also recently visited NASA’s Marshall Space Flight Center in Huntsville, Alabama and Langley Research Center in Hampton, Virginia, along with United Launch Alliance’s Decatur, Alabama facility, to thank employees for the work they did to make Orion’s December flight test successful. The week of March 23, the leadership team will visit NASA’s Goddard Space Flight Center in Greenbelt, Maryland, which provided spacecraft communications support during the flight test, as well as NASA Headquarters in Washington.

am managers also recently visited NASA’s Marshall Space Flight Center in Huntsville, Alabama and Langley Research Center in Hampton, Virginia, along with United Launch Alliance’s Decatur, Alabama facility, to thank employees for the work they did to make Orion’s December flight test successful. The week of March 23, the leadership team will visit NASA’s Goddard Space Flight Center in Greenbelt, Maryland, which provided spacecraft communications support during the flight test, as well as NASA Headquarters in Washington. ill be used by engineers to examine the char layers and degree of erosion, and along with other data, will be analyzed to determine whether any improvements need to be made to the heat shield before Orion begins carrying astronauts to deep space destinations.

ill be used by engineers to examine the char layers and degree of erosion, and along with other data, will be analyzed to determine whether any improvements need to be made to the heat shield before Orion begins carrying astronauts to deep space destinations. ership team will travel to several places in California, Washington, Utah, Alabama and Maryland, to name just a few states they’ll visit, to meet the people who invested time and energy into the countless elements that had to work for the flight to be successful.

ership team will travel to several places in California, Washington, Utah, Alabama and Maryland, to name just a few states they’ll visit, to meet the people who invested time and energy into the countless elements that had to work for the flight to be successful.