Technicians and engineers continue to make progress manufacturing core stages that will help power NASA’s Space Launch System (SLS) rocket for its second and third flights. NASA and Boeing, the lead contractor for the core stage, are in the process of conducting one of the biggest Artemis II milestones: assembling the top half of the core stage.

The 212-foot tall core stage for the SLS rocket is the largest rocket stage NASA has ever produced. The five individual elements that make up the core stage – the forward skirt, liquid oxygen tank, intertank, liquid hydrogen tank, and the engine section – are manufactured and assembled at NASA’s Michoud Assembly Facility in New Orleans. Together, the elements will supply propellant, vehicle control, and power to the four RS-25 engines at the bottom of the stage to produce more than 2 million pounds of thrust to send missions to the Moon.

The team manufactures every SLS core stage in Michoud’s 43-acre building which provides more than enough space for crews to work in tandem to build the core stages for Artemis II and Artemis III, the second and third flights of the SLS rocket and the first crewed missions of NASA’s Artemis program.

It takes teamwork to build a super heavy-lift rocket. Look behind the scenes at the work being done at NASA’s rocket factory:

Coming together to build the upper part of the rocket

After all the core stage’s large five structures are built and outfitted, these structures are connected during three major joining operations. For first one, the forward or upper parts of the core stage are joined together for the first time. First, teams move the intertank into an assembly area and connect it to the liquid oxygen tank, and then they add the forward skirt to form the entire upper part of the SLS core stage.

Crews with NASA and Boeing, the core stage prime contractor, recently moved the Artemis II intertank, above, to the assembly area where the three components will be stacked.

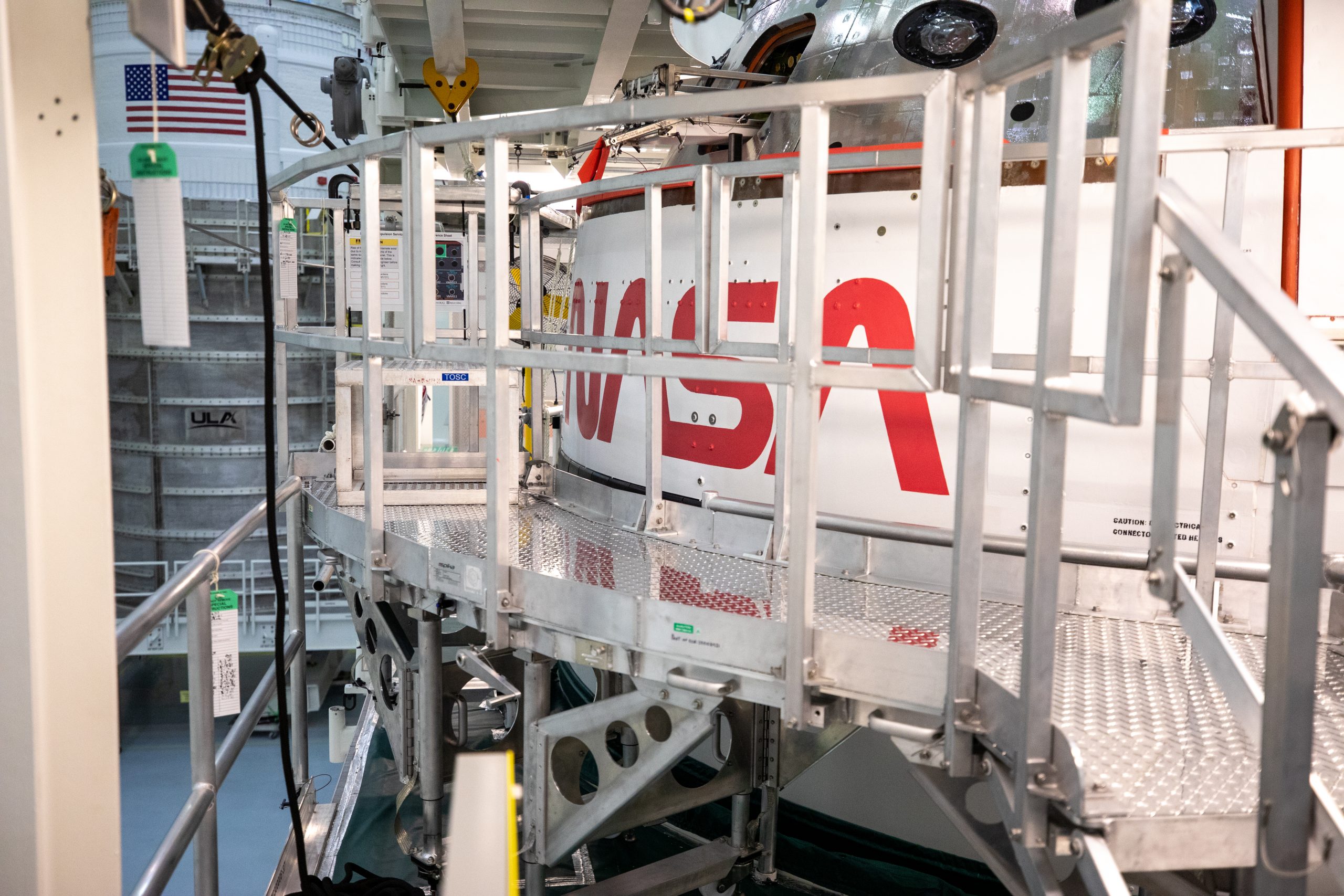

The Artemis II forward skirt, pictured above, has been outfitted and is ready for integration with the other large core stage structures. The forward skirt houses flight computers, cameras, and avionics systems. It is located at the very top of the core stage and connects to the upper part of the rocket.

Moving through the manufacturing process

The core stage has two huge cryogenic liquid propellant tanks that collectively hold more than 733,000 gallons of liquid propellant to help launch the Space Launch System rocket to the Moon. Moving the immense hardware, especially the two propellant tanks, around the factory is a delicate process.

Teams carefully orchestrate every step of every lift and transport inside and outside the rocket factory. To safely and securely move hardware, they use special transporters and cranes that are designed to contain, hold, and handle the weight of each element. Above, teams move the more than 130-foot-tall liquid hydrogen tank to the same area as the liquid oxygen tank. Both propellant tanks will be used for Artemis II.

The aisles at Michoud are extra-wide to ensure large hardware can be transported throughout the factory. For the next phase of manufacturing, crews recently moved the boat-tail, a fairing-like cover that attaches to the engine section on the bottom of the core stage. The boat-tail is shown in the image foreground, and the engine section for Artemis II can be seen in the background covered with scaffolding. The four RS-25 engines for the SLS rocket will be mounted inside the engine section, and the boat-tail helps to protect and cover most of the four RS-25 engines’ critical systems.

It’s all in the details

As crews prepare the core stage elements that will be used for Artemis II for assembly and integration, the hardware for Artemis III is being welded in other areas of the factory. Engineers and technicians use friction-stir welding methods to connect the panels that make up each piece of hardware together and build larger structures. Fusion welding is traditional welding, and it uses heat to plug holes left by machines welding the larger pieces as well as for any necessary weld repairs.

Welding processes help to create the shells, or outside, of the core stage structures. Above, the engine section for Artemis III comes together in the Vertical Weld Center at Michoud. They are made by connecting panels such as the one in the front of this image. The engine section has been completed and moved to another part of the factory. One of the biggest tasks ahead, is outfitting it with a network of internal components and systems that connect to the RS-25 engines.

In May, the core stage team will begin work on the Artemis IV core stage, so three stages will be under construction at the same time. Because of the factory’s size, state-of-the-art equipment, and manufacturing processes, skilled workers can produce multiple rocket stages to power NASA’s next-generation Moon missions through the Artemis program.

NASA is working to land the first woman and the first person of color on the Moon. SLS and Orion, along with the human landing system and the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission.

The intertank contains avionics that are the “brains” of the rocket. It also serves as one of the main attach points for the twin solid rocket boosters that work with the core stage to send SLS to space. The core stage will supply propellant and power to the four RS-25 engines at the bottom of the stage to produce the remaining 2 million pounds of thrust needed to send the Artemis II mission to orbit.

The intertank contains avionics that are the “brains” of the rocket. It also serves as one of the main attach points for the twin solid rocket boosters that work with the core stage to send SLS to space. The core stage will supply propellant and power to the four RS-25 engines at the bottom of the stage to produce the remaining 2 million pounds of thrust needed to send the Artemis II mission to orbit.