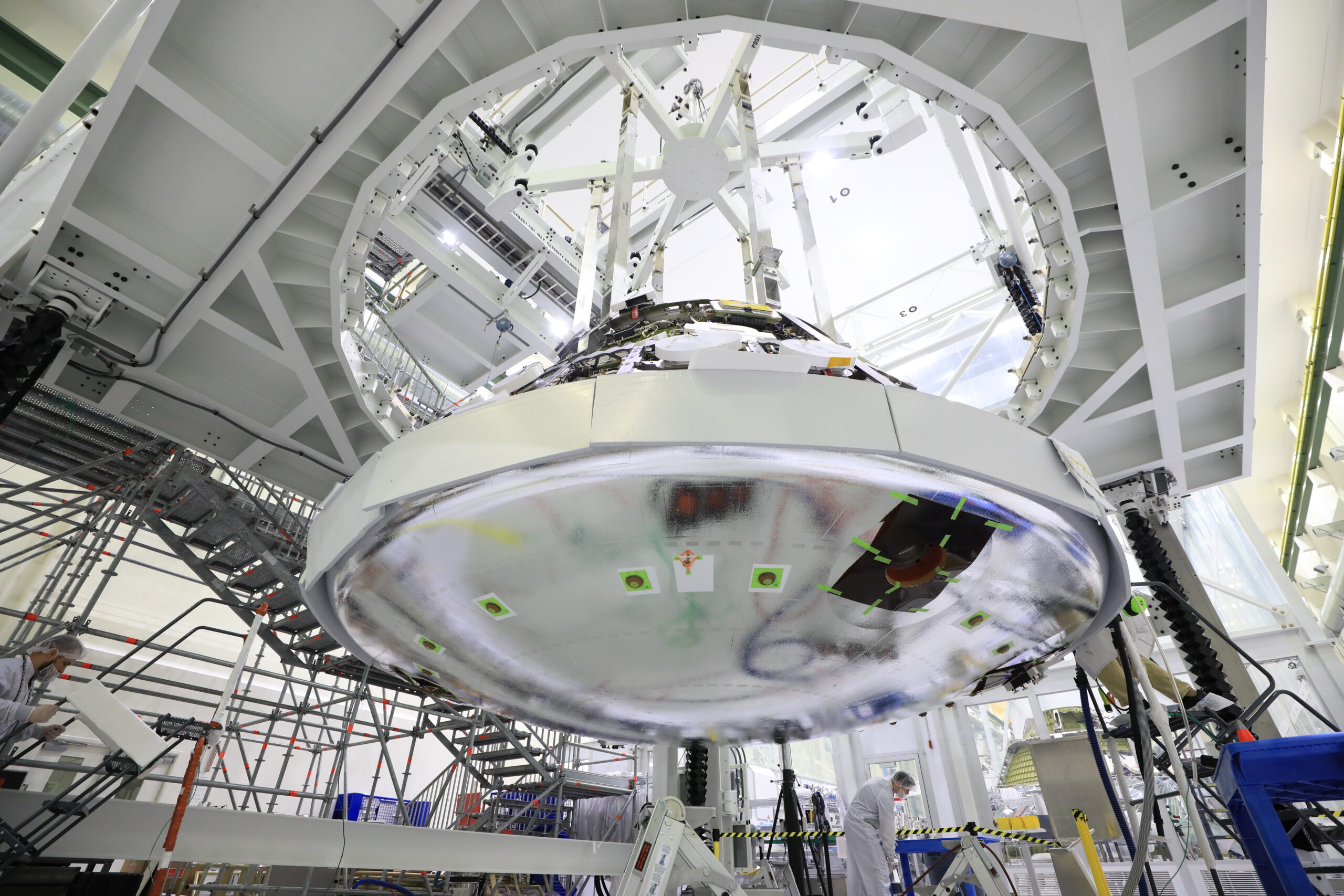

Teams at NASA’s Michoud Assembly Facility in New Orleans have structurally joined all four RS-25 engines onto the core stage for NASA’s Artemis II Moon rocket. The flight test is the agency’s first crewed mission under Artemis.

Technicians added the first engine to NASA’s SLS (Space Launch System) rocket core stage Sept. 11. Teams installed the second engine onto the stage Sept. 15 with the third and fourth engines Sept. 19 and Sept. 20. Technicians with NASA, Aerojet Rocketdyne, an L3Harris Technologies company and the RS-25 engines lead contractor, along with Boeing, the core stage lead contractor, now will focus efforts on the complex task of fully securing the engines to the stage and integrating the propulsion and electrical systems within the structure.

The SLS core stage, at 212 feet, is the backbone of the Moon rocket. Its two huge propellant tanks provide more than 733,000 gallons of super-chilled liquid propellant to the four RS-25 engines, while the stage’s flight computers, avionics, and electrical systems act as the “brains” of the rocket. During Artemis II, the RS-25 engines will together provide more than 2 million pounds of thrust for eight minutes of flight, helping to send the Artemis II crew beyond low-Earth orbit to venture around the Moon.

NASA is working to land the first woman and first person of color on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with Orion and the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission.

For more on NASA SLS visit: