During the months of the assembly operations, the Ares I-X team stuck a camera in the Vehicle Assembly Building to record everything.

The result…10 months of hard work stuffed into 5 minutes and 45 seconds. Watch the video on YouTube

Enjoy!!

During the months of the assembly operations, the Ares I-X team stuck a camera in the Vehicle Assembly Building to record everything.

The result…10 months of hard work stuffed into 5 minutes and 45 seconds. Watch the video on YouTube

Enjoy!!

The Ares I-X Launch Team spent the day in the firing room preparing for the upcoming launch. The team conducted a simulation of the last 50 minutes in the launch countdown.

Now this is no walk in the park simulation. The team was thrown different scenarios and issues that could come up during the actual launch countdown, including issues that could ultimately cause a launch delay. In fact, this specific set of simulations was focused on problems that the sim (simulation) team knew would prevent a launch in order to give the I-X launch team practice on handling emergency and stressful situations. All of this is designed to identify any problems in the countdown planning process and any vague areas in the launch commit criteria while stressing the team beyond what we ever expect to see on a real launch day. Sounds like fun, huh?

The simulation required support from Kennedy’s Firing Room 1, Cape Canaveral Air Force Station’s Hangar AE, the Software Integration Lab, or SIL, and team members from multiple NASA Centers. This was the first simulation with the entire team. The next simulation is planned for the end of September and will include the Launch Advisory Management Team.

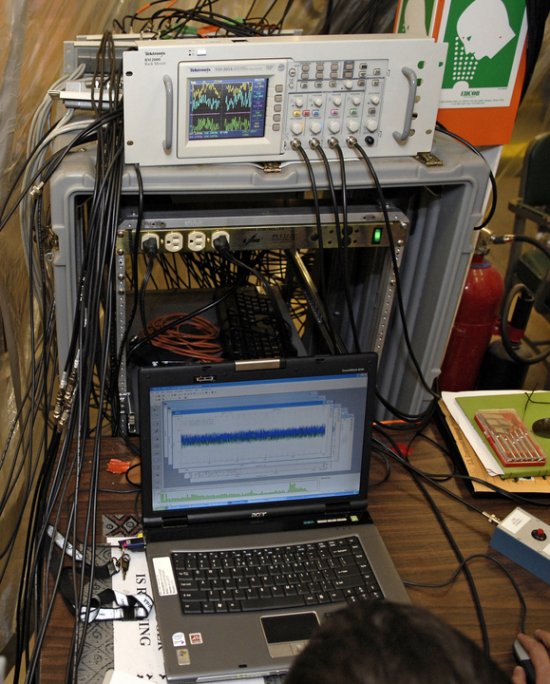

Even though the rocket is now stacked and sitting on the mobile launch platform in Kennedy Space Center’s VAB, there is still a lot of testing and prep work to be done before it’s ready to roll out to the pad. Over the weekend (Aug. 29-30) the rocket underwent two days of modal testing to make sure it’s ready to stand up to the environments it’s about to find itself in.

The testing required a total of 44 accelerometers — a device that measures movement — to be installed on the flight test vehicle. And to put those on the vehicle it took more than 27,000 feet of cable. That’s more than 5 miles!

During the testing, vibrations were mechanically introduced into the rocket by four hydraulic shakers simulating the same kind of vibrations expected during flight so the effects could be monitored. A sway of the vehicle was then manually introduced (with a little help from Mission Manager, Bob Ess and Deputy Mission Manager Steve Davis) to create a lateral, back and forth motion so the team could measure how the rocket reacts.

Here’s a little fast-motion clip of Steve and Bob rocking the rocket (Flickr).

This part of the testing was important because it simulated the conditions the rocket could experience as it rolls out to Kennedy’s Launch Pad 39B, the wind conditions at the launch pad before it launches, and what it would experience during flight at first stage ignition.

NASA did some similar testing years ago on the Saturn V at Kennedy Space Center in the 60s. For those tests a group of people sat up on a platform and rocked the vehicle back and forth with their sneakered feet from one side, while another group of people pulled on the rocket with ropes from the other side. The group appropriately named it the “Tennis Shoe Test.”

The completion of the Ares I-X modal testing is an important step for the mission because it clears the way for next week’s Integrated Vehicle Power Application or systems power up test, which will be the first time that all of the electrical systems, control boxes and sensors will be turned on together and powered up.

Now this is something you’ve really got to see!

For the first time in more than 25 years, a new space vehicle is assembled and rarin’ to go in KSC’s Vehicle Assembly Building. Standing more than 320 feet tall, the rocket is almost twice as tall as a shuttle stack.

A crane hoisted the simulator launch abort system tower off the floor and placed it on top of the Ares I-X to complete he rocket stack.

It’s obviously a huge milestone! Now you can really get a feel for the scope of the vehicle.

The test rocket has been assembled on the top of a modified mobile launcher that used to be used by the shuttle.

Now that it is assembled, there will be extensive tests run on all the systems, including the set of complex instruments that will measure the rocket’s movements as it launches and the first stage separates.

These tests will include a process called “modal testing,” which will shake the stack slightly to test stiffness of the rocket including the pinned and bolted joints and make sure the rocket can handle the strain of launch and ascent. While those tests are conducted, a team of about 30 launch controllers also will practice their roles in the firing room preparing for its targeted launch in late October.

![]()

![]()

![]()

The Super Stack 1 assembly is now complete with the mating (stacking) of the forward assembly to the fifth segment simulator. Stack one is made up of eight individual pieces: interstages 1 and 2, the frustum, the forward skirt extension, the forward skirt and the aft, center and forward segments of the fifth segment simulator. It also includes two internal elements, the roll control system and the first stage avionics module.

All five super stack assemblies are now complete in High Bay 4 of the VAB and are ready for stacking on the mobile launcher platform in High Bay 3 later this month.

Just so you know, the reason the rocket is separated into these super stacks has to do with the height and weight of each piece for crane loads during lifting operations.

Super Stack 2: Upper Stage Simulator “Tuna Cans” segment 1

Super Stack 3: Upper Stage Simulator “Tuna Cans” segments 2, 3, 4, 5

Super Stack 4: Upper Stage Simulator “Tuna Cans” segments, 6, 7

Super Stack 5: Spacecraft Adapter, Service Module, Crew Module and Launch Abort System

Stacking is set to begin for the Ares I-X vehicle on Wednesday, July 8 in the Vehicle Assembly Building at Kennedy Space Center. It’s been a long time since the workers in the VAB have seen a new vehicle. In fact, it’s been 25 years since a new vehicle was stacked.

Following nearly three years of work by thousands of dedicated team members, the Ares I-X vehicle is ready for stacking on the Mobile Launch Platform, or MLP, in the Vehicle Assembly Building at Kennedy Space Center.

Over the last week, the management team has met for reviews. Today, a “go” was given for the stacking operations. All of the modification work has been completed in VAB High Bay 3, as well as the Mobile Launch Platform, in preparation for the new Ares I-X vehicle.

Tomorrow, the Ares I-X aft assembly, composed of the aft skirt and aft motor segment, will be rolled from the Rotation Processing and Surge Facility to the VAB and lifted by overhead crane and placed on the MLP. (Be sure to check out the KSC gallery for photo updates.)

Over the next month, the stacking operations will continue with the additional motor segments, simulated upper stage segments and the vehicle will be completed when the simulated crew module and launch abort system is added to the top. (There will be a time-lapse camera. NASA will be posting video and images.)

We will keep you posted on this blog, on our Facebook page and Twitter.

Let the stacking begin!

The forward assembly, which is affectionately known around here as the “snow cone,” was rolled out of the Assembly Refurbishment Facility this morning on its way to the Vehicle Assembly Building. Employees and media came out to get a peek at the hardware.

The assembly was rolled into the transfer aisle of the Vehicle Assembly Building, where it will wait to be lifted by crane into the high bay where the upper stage of the rocket is being assembled into its five super stacks. When these stacking operations begin later this month, it will be the first time a new vehicle has been stacked on NASA’s Mobile Launch Platform in more than 25 years!

The forward assembly connects the first stage motor segments to the upper stage simulator. Weighing more than 40,000 pounds, the assembly houses three newly designed descent parachutes for first stage recovery.

With 300 employees looking on, the Ares I-X aft skirt rolled out of the Assembly Refurbishment Facility. Senior management including Kennedy Center Director Bob Cabana, Mission Manager Bob Ess, ATK Program Manager Joe Oliva and United Space Alliance Associate Program Manager Roger Elliot spoke at the “pep rally” type event.

The aft skirt is on its way to the Rotation Processing and Surge Facility where it will be attached to the aft motor segment later this week, forming the aft assembly. Although this was an aft skirt for the shuttle program, the team made many modifications for this new vehicle. Some modifications include adding deceleration and tumble motors, avionics and a controller for the auxiliary power unit.

Once the aft assembly is complete, it will be moved to the Vehicle Assembly Building to begin stacking operations in late June.

Work continues as we put together the pieces of hardware for the Ares I-X flight test scheduled for later this year. Two of the newly designed and manufactured segments, called the forward skirt and the forward skirt extension, were joined together earlier this month in the Assembly Refurbishment Facility at Kennedy Space Center. They are two of sixteen pieces that have been put together so far. When we put all 26 pieces together, we’ll say we’ve got a rocket. So, in a way, I guess you could say we’re more than half way there.

The 16,000-pound forward skirt extension is a proof-of-concept, or demonstration of this prototype, that incorporates 18 months of design work and eight months of manufacturing. It’s made of an aircraft-grade aluminum structure and houses three newly designed parachutes that will bring the first stage of the Ares I-X to a safe splashdown about 150 miles out in the Atlantic Ocean, east of Cape Canaveral.

The 14,000-pound forward skirt is constructed entirely of the same kind of armored steel used on Abrams A-1 tanks and armored Humvees. It is designed to simulate the stage that will contain the Ares I first stage electronics and provide access to the top of the motor. It also contains two video cameras that will capture the main parachutes deployment. Once attached, this assembly will be joined to the frustum, another new segment made especially for Ares I-X, and then be moved to the Vehicle Assembly Building for stacking.

The launch of STS-125 was absolutely beautiful! That’s one of the best things about working in the space business — getting to watch the shuttle launch. If you haven’t ever had the chance to see a shuttle launch in person you might be interested to know that there is a whole lot going on at KSC leading up to the launch. For the few days before launch all of KSC is bustling with people from all over the world who have come to see or help out with the launch.

This time, two days before launch, the Ares I-X team took an overflowing busload of media to the Vehicle Assembly Building for an Ares I-X media opportunity. As we walked into the building, the media were in awe at how big the rocket is going to be. Until you see it in person, it is hard to get a reference for how big 327 feet can be.

We proceeded down to High Bay 4 to meet up with Bob Ess, mission manager, and Steve Davis, his deputy. We split up into groups and toured the bay from the floor as well as from the fifth level. The media had many questions and were excited to see how much progress we have made in processing the upper stage.

Videos, pictures and pens were going a mile a minute trying to capture every little detail. It was hard to get the media to leave the VAB and get back on the bus! If we let them, they would have stayed all day. Not to worry, we’ll be back in a month or less.