NASA and Boeing will hold a joint media teleconference at noon EDT on Tuesday, May 3, to discuss the agency’s Boeing Orbital Flight Test (OFT-2) mission and provide an update on spacecraft readiness.

The teleconference includes the following participants:

- Kathryn Lueders, associate administrator, Space Operations Mission Directorate, NASA Headquarters

- Steve Stich, manager, Commercial Crew Program, NASA’s Kennedy Space Center in Florida

- Joel Montalbano, manager, International Space Station Program, NASA’s Johnson Space Center in Houston

- Michelle Parker, vice president and deputy general manager, Space and Launch, Boeing

- Mark Nappi, vice president and program manager, CST-100 Starliner, Boeing

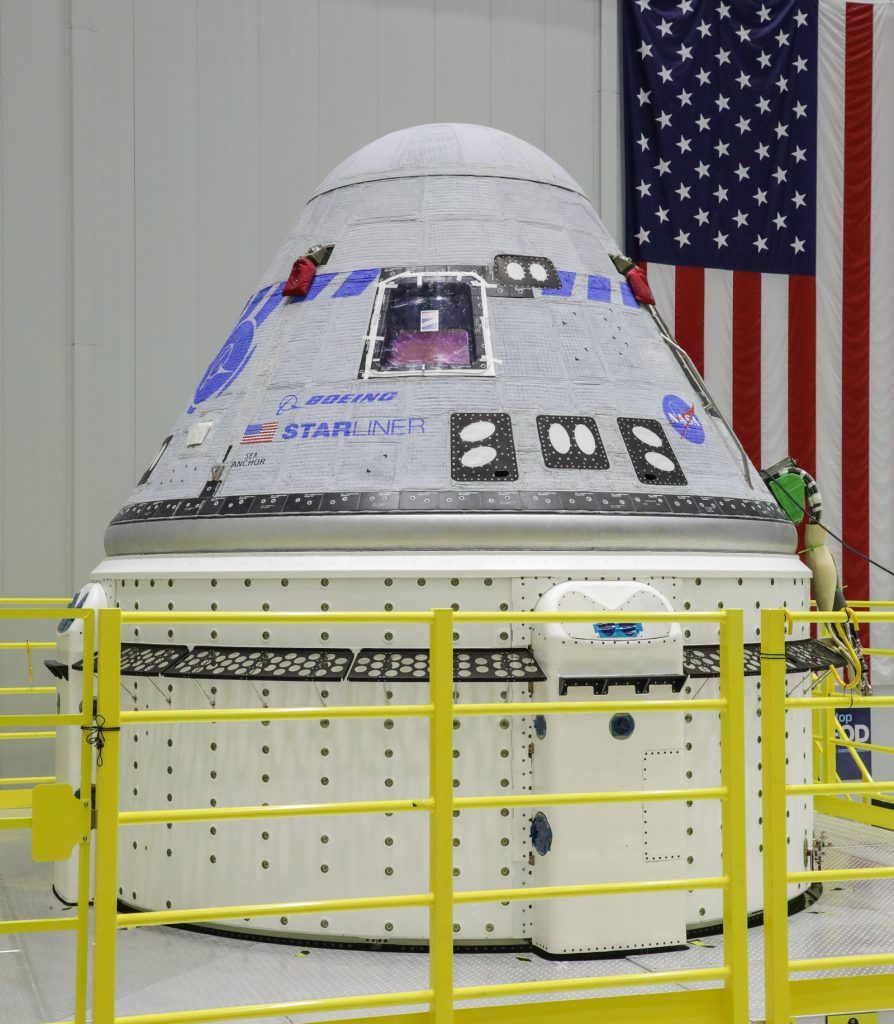

OFT-2 is scheduled to launch on Thursday, May 19, from Space Launch Complex-41 at Cape Canaveral Space Force Station in Florida. Boeing’s uncrewed CST-100 Starliner will launch atop a United Launch Alliance Atlas V rocket for its flight test to the International Space Station as part of NASA’s Commercial Crew Program.

Starliner is expected to arrive at the space station for docking about 24 hours later with more than 500 pounds of NASA cargo and crew supplies. After a successful docking, Starliner will spend five to 10 days aboard the orbiting laboratory before returning to Earth in the western United States. The spacecraft will return with nearly 600 pounds of cargo, including reusable Nitrogen Oxygen Recharge System (NORS) tanks that provide breathable air to station crew members.

Media wishing to participate in the OFT-2 mission overview news teleconference must RSVP by 11 a.m., Tuesday, May 3, by emailing the Kennedy newsroom at ksc-newsroom@mail.nasa.gov.

More details about the mission and NASA’s commercial crew program can be found by following the commercial crew blog, @commercial_crew and commercial crew on Facebook.