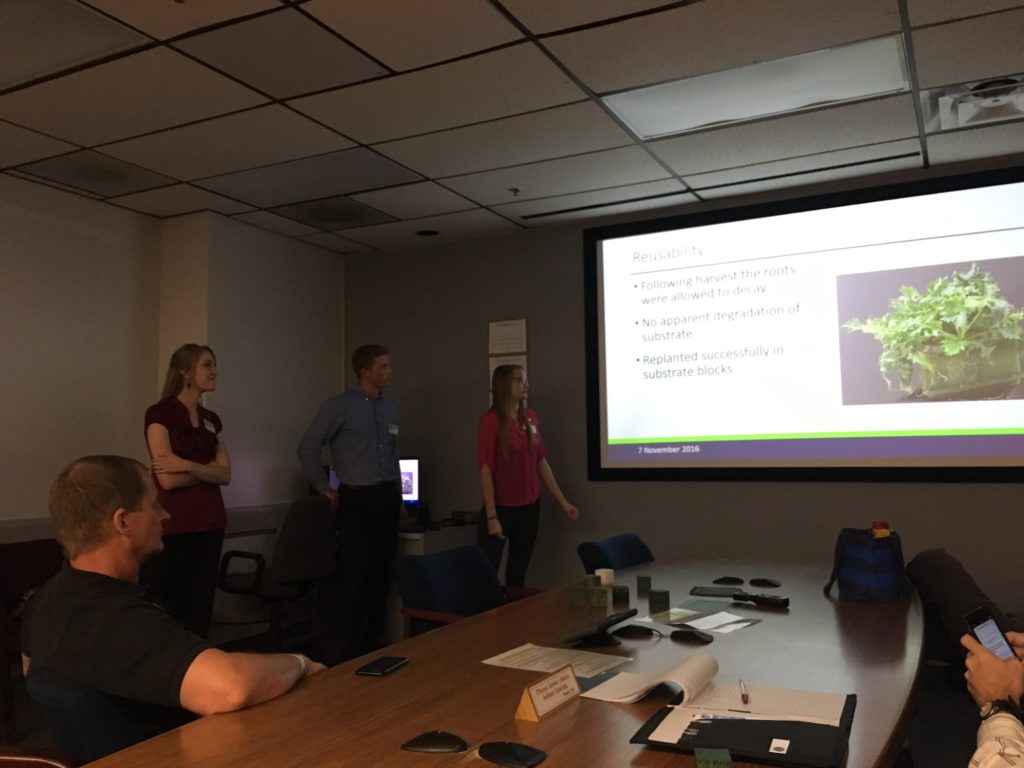

Students from Utah State University presented Eden, a plant chamber that could be operated autonomously during long-term spaceflight missions, while visiting Kennedy Space Center Nov. 7. This project is part of NASA’s eXploration Systems and Habitation (X-Hab) Academic Innovation Challenge series, and also serves as a pathfinder for the type of technol ogy needed for future long duration missions beyond low-Earth orbit.

ogy needed for future long duration missions beyond low-Earth orbit.

“The Utah State University X-HAB team did a fantastic job developing an innovative project,” commented Dr. Gioia Massa, a scientist who works on food production in space. “Their Eden X-HAB project demonstrated a very novel approach to sustaining plant growth in microgravity, with a 3-D printed substrate that could be a revolutionary way to provide water and nutrients to plants.”

Eden would make use of the 3-D printed substrate to deliver water, oxygen, and nutrients to plant roots in microgravity conditions. Students built an Eden prototype and grew plants in a 30-day test. This type of plant growth system would improve the autonomy of current plant growth systems in use aboard the International Space Station to make them more practical for limited crew time missions.