NASA and Boeing completed a joint Crew Flight Test checkpoint review May 25 ahead of the first flight of Starliner with astronauts to the International Space Station. During the checkpoint, mission teams reviewed open work ahead of launch planned no earlier than July 21, including emerging issues that need a path to closure prior to a decision to fuel the spacecraft in June.

“We are taking a methodical approach to the first crewed flight of Starliner incorporating all of the lessons learned from the various in-depth testing campaigns, including Starliner’s flight tests and the agency’s verification efforts,” said Steve Stich, manager of NASA’s Commercial Crew Program. “All Orbital Flight Test-2 anomalies are closed. In addition to the closeout of ongoing work, the team remains vigilant on tracking new technical issues as we complete certification for crewed flight.”

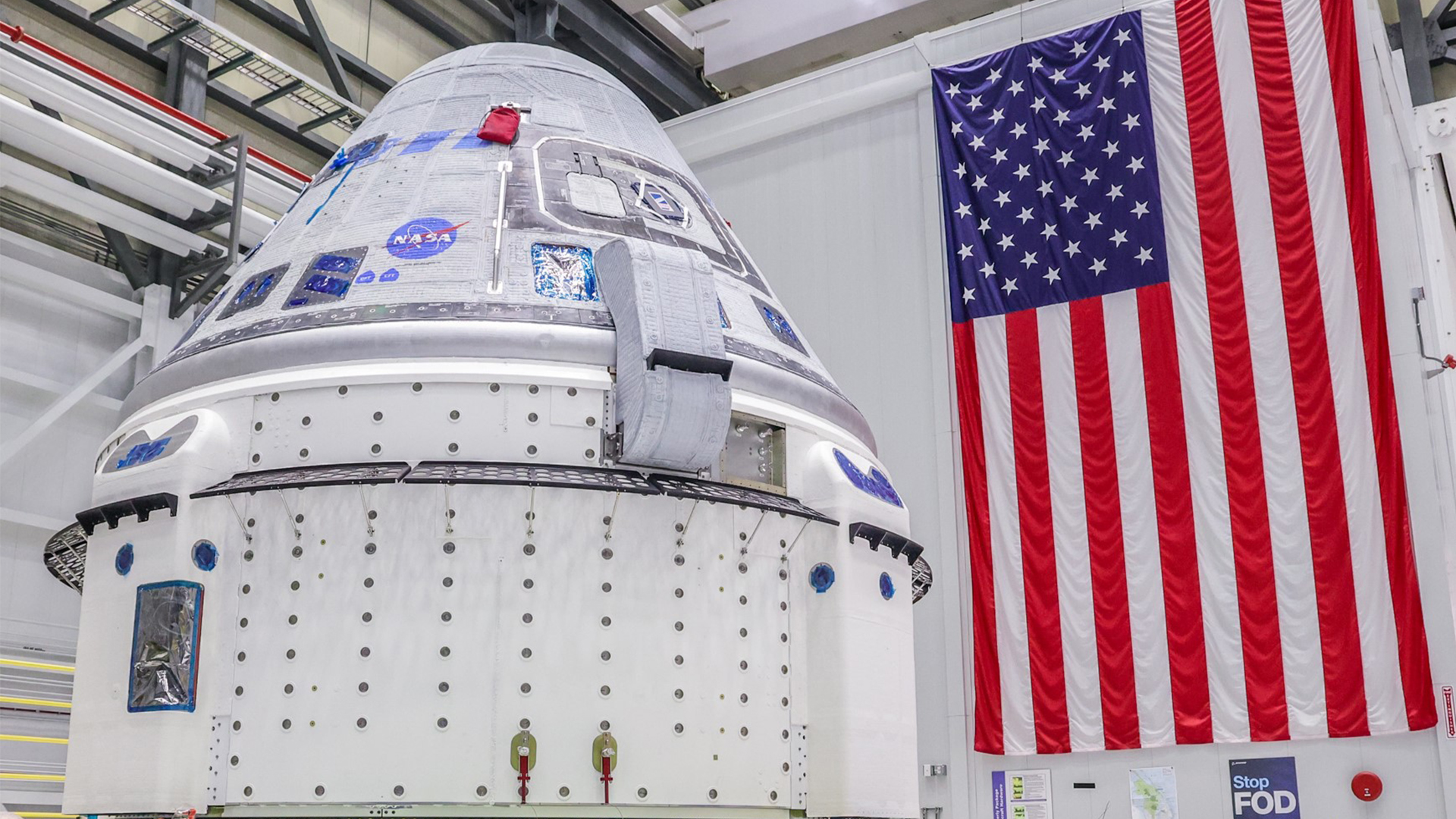

As part of the ongoing effort, 95% of the Crew Flight Test certification products are complete. This includes approval of Starliner’s crew module batteries, based on additional testing and analysis, along with post-certification flight mitigations and a proposed battery upgrade for future missions. Teams are conducting final spacecraft closeouts and preparing for upcoming hardware milestones, including spacecraft fueling, spacecraft rollout to the launch site, and integration with the United Launch Alliance Atlas V rocket.

While the team continues to work the remaining certification products, they also are working resolution paths on the following items:

Teams will remove and replace a by-pass valve on the active thermal control system, which is located on the Starliner service module and is used to flow coolant into the system to cool the onboard avionics. The Starliner team is replacing the valve that was restricting flow to one of two redundant loops, and running a diagnostic to confirm the suspected issue with the malfunctioning hardware. This work is expected to take about a week with no overall impact to the launch schedule at this time.

Engineers also are working to evaluate any elevated risk from a specific type of tape used on the spacecraft to protect wires from chafing. Although the tape is commonly used in spaceflight, the adhesive properties of the tape could present a flammability risk under certain conditions. NASA and Boeing are evaluating this material and the system’s overall wiring protection to confirm it is acceptable for crewed flight. Those efforts are ongoing and are expected to complete before Boeing begins fueling operations on the spacecraft.

NASA and Boeing also are working to reassess Starliner’s parachute system margins based on new data reviews as part of the ongoing design certification process. Engineers are reviewing the overall efficiency of certain joints within the parachute system to confirm they meet all required factors of safety for crewed flight.

“Crew safety remains the highest priority for NASA and its industry providers, and emerging issues are not uncommon in human spaceflight especially during development,” said Stich. “If you look back two months ago at the work we had ahead of us, it’s almost all complete. The combined team is resilient and resolute in their goal of flying crew on Starliner as soon as it is safe to do so. If a schedule adjustment needs to be made in the future, then we will certainly do that as we have done before. We will only fly when we are ready.”

Starliner spacecraft fueling is expected to begin as early as mid-June, and there is some operational flexibility in that timeline that can be used if needed. Teams will continue to monitor the forward work and determine whether an adjustment in the current launch date is needed. An update on the team’s progress will be provided in the coming weeks.

Find out more about NASA’s Commercial Crew Program at: https://www.nasa.gov/commercialcrew