Weather conditions near multiple splashdown zones off the coast of Florida remain unfavorable for the return of NASA’s SpaceX Crew-8 from the International Space Station. Mission managers continue to monitor conditions as weather is expected to remain unfavorable for several days. The next weather briefing is planned for 11 a.m. EDT, on Friday, Oct. 18. If weather conditions improve, NASA and SpaceX will target no earlier than 3:05 a.m., Sunday, Oct. 20, for undocking from the space station.

Tag: CCP

NASA, SpaceX Continue Evaluating Weather for Crew-8 Return

Mission managers continue to monitor weather conditions near the splashdown zones off the Florida coast ahead of returning NASA’s SpaceX Crew-8 mission from the International Space Station. Current forecasts indicate unfavorable conditions over the next several days. The next weather briefing is planned for 11 a.m. EDT Wednesday, Oct. 16. If weather conditions improve, NASA and SpaceX will target no earlier than 3:05 a.m., Friday, Oct. 18, for undocking from the space station.

NASA’s SpaceX Crew-9 Duo Lands at Florida Spaceport

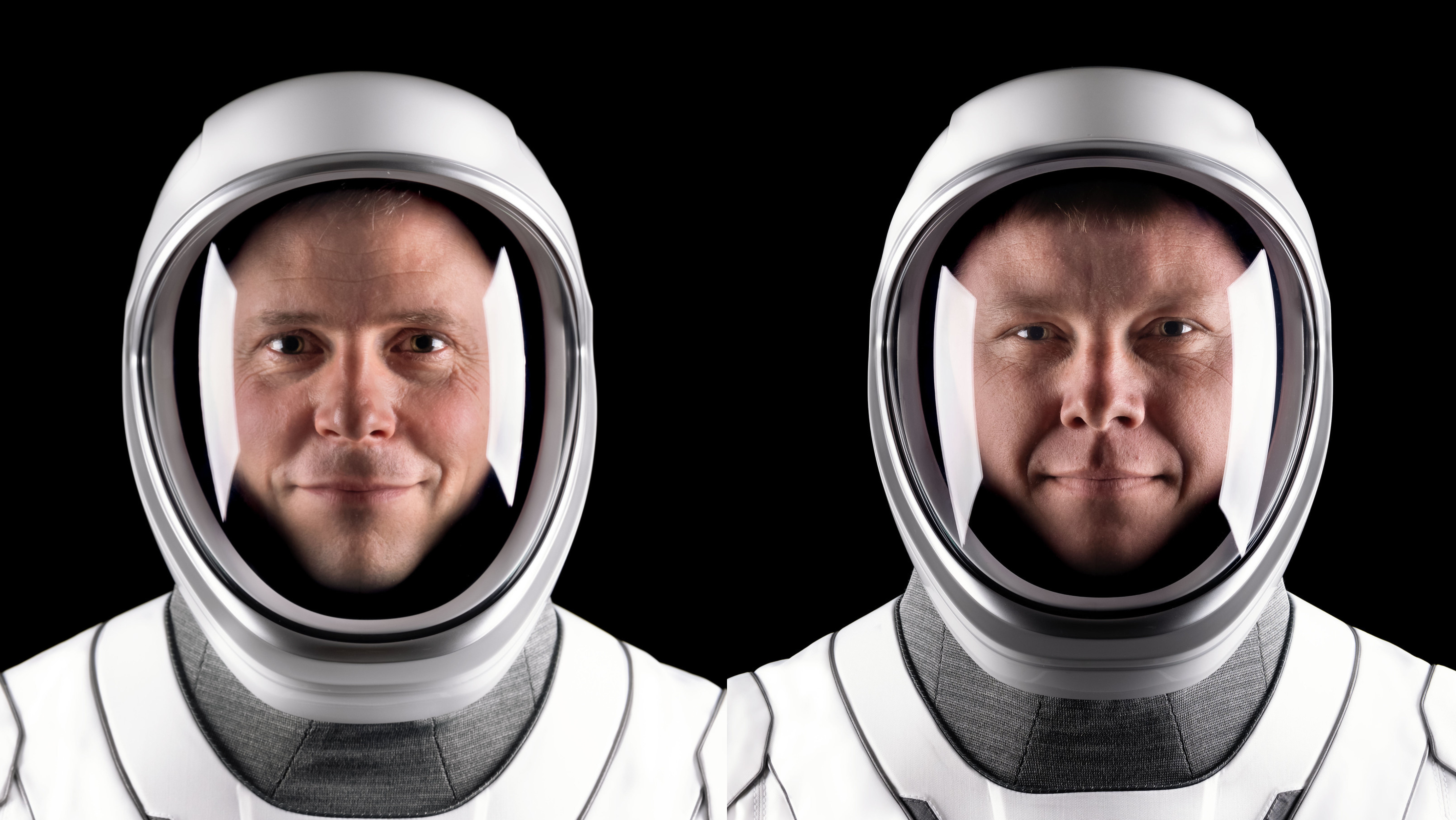

NASA astronaut Nick Hague, commander, and Roscosmos cosmonaut Aleksandr Gorbunov, mission specialist, arrived at the Launch and Landing Facility at NASA’s Kennedy Space Center in Florida just moments ago on Saturday, Sept. 21.

NASA leaders will greet the agency’s SpaceX Crew-9 at 1:30 p.m. EDT for a brief welcome ceremony with the following participants:

- Kelvin Manning, deputy director, NASA’s Kennedy Space Center

- Dana Hutcherson, deputy program manager, NASA’s Commercial Crew Program

- NASA astronaut Nick Hague

- Roscosmos cosmonaut Aleksandr Gorbunov

The ceremony will stream live on NASA+ and the agency’s website. Learn how to stream NASA content through a variety of platforms, including social media.

Hague and Gorbunov will quarantine at the Neil A. Armstrong Operations and Checkout Building at Kennedy. While there, they’ll conduct a dry dress rehearsal of the mission, sleep shift to align their resting and waking periods with mission requirements, rehearse flight procedures, as well as make calls to family and friends.

The crew is scheduled to launch aboard a SpaceX Falcon 9 rocket and Dragon spacecraft to the International Space Station at 2:05 p.m. EDT on Thursday, Sept. 26, from Space Launch Complex-40 at Cape Canaveral Space Force Station.

NASA’s SpaceX Crew-9 Leaves Houston for Florida Space Coast

In a matter of hours on Saturday, Sept. 21, NASA’s SpaceX Crew-9 will land at the Launch and Landing Facility at NASA’s Kennedy Space Center in Florida.

NASA astronaut Nick Hague, commander, and Roscosmos cosmonaut Aleksandr Gorbunov, mission specialist, left Ellington Field near the agency’s Johnson Space Center in Houston and will continue to quarantine at Kennedy.

NASA leaders will hold a brief welcome ceremony when Hague and Gorbunov land around 1:30 p.m. EDT. Watch the event live on NASA+ and the agency’s website. Learn how to stream NASA content through a variety of platforms, including social media.

Liftoff is targeted for 2:05 p.m. EDT on Thursday, Sept. 26, from Space Launch Complex-40 at Cape Canaveral Space Force Station in Florida. Crew-9 will launch aboard a SpaceX Falcon 9 rocket and Dragon spacecraft. This is the first time a human spaceflight mission will launch from the pad.

More details about the launch will be posted on the mission blog, @commercial_crew on X, or commercial crew on Facebook.

Starliner Lands in New Mexico

At 12:01 a.m. EDT, Boeing’s uncrewed Starliner spacecraft landed at White Sands Space Harbor in New Mexico.

NASA will provide coverage of a post-landing news conference at 1:30 a.m. on NASA+, the NASA app, YouTube, and the agency’s website.

The following will participate in the news conference:

- Joel Montalbano, deputy associate administrator, Space Operations Mission Directorate at NASA Headquarters in Washington

- Steve Stich, manager, Commercial Crew Program, NASA Kennedy Space Center in Florida

- Dana Weigel, manager, International Space Station, NASA Johnson

Learn more about the mission by following the commercial crew blog, @commercial_crew on X, and @NASACommercialCrew on Facebook.

Starliner Spacecraft Airbags Inflate for Landing

The uncrewed Boeing Starliner spacecraft is less than two minutes from landing on U.S. soil after spending three months at the International Space Station. Starliner is the first American-made orbital crew capsule designed to perform a ground landing as a reusable spacecraft.

The base heat shield separated from the spacecraft to allow the six airbags to inflate and brace for a ground landing. The three main parachutes are also slowing down the uncrewed capsule.

The airbags are filled with nitrogen to cushion Starliner’s landing at White Sands Space Harbor in New Mexico. The NASA and Boeing landing and recovery team is stationed at a holding zone near the landing site. After landing, technicians will use equipment to “sniff” the spacecraft for any lingering hypergolic fluids before approaching Starliner, opening the hatch, and unloading time-critical cargo. The spacecraft will then be transported to Boeing facilities at NASA’s Kennedy Space Center in Florida.

Starliner Deploys Drogue, Main Parachutes

NASA’s coverage continues as Boeing’s uncrewed Starliner spacecraft reaches the final stages of landing.

Around 30,000 feet after atmospheric re-entry, the forward heat shield separated from the spacecraft and the drogue parachutes inflated to help slow down the uncrewed capsule.

About 45 seconds later, at around 8,000 feet, the drogue parachutes separated to make way for three larger main parachutes to deploy, slow down Starliner to 4 miles per hour, and allow an airbag-assisted landing.

Soon, the base heat shield will jettison to expose six airbags that will inflate to assist in a soft landing at White Sands Space Harbor in New Mexico in just a few minutes at 12 a.m. EDT, Saturday, Sept. 7.

Watch landing coverage on NASA+, the NASA app, and the agency’s website. Learn how to stream NASA programming through a variety of platforms including social media.

Starliner Completes Entry Interface

Boeing’s uncrewed Starliner spacecraft successfully completed entry interface over the Pacific Ocean.

During re-entry to Earth’s atmosphere, Starliner will begin to slow down from orbital velocity at 17,500 miles per hour.

The next milestone will be separation of the forward heat shield and deployment of two drogue parachutes to slow Starliner’s speed and drag.

The spacecraft is expected to land at approximately 12 a.m. Saturday, Sept. 7, at White Sands Space Harbor in New Mexico.

NASA’s Coverage Continues, Starliner Begins Re-entry

NASA’s coverage continues on NASA+, the NASA app, and YouTube, and the agency’s website as Boeing’s uncrewed Starliner spacecraft begins entry interface 400,000 feet above Earth.

As the hottest part of re-entry, the spacecraft’s heat shield will reach 3,000 degrees Fahrenheit as it enters the atmosphere.

Starliner is equipped with an ablative heat shield containing a layer of plastic resin that will heat up to gas and carry the heat away from the crew capsule through convection. This process helps keep the temperature inside the capsule around 70 degrees Fahrenheit. Similar heat shields were used on Mercury, Gemini, and Apollo spacecrafts.

The spacecraft is expected to land at approximately 12 a.m. Saturday, Sept. 7, at White Sands Space Harbor in New Mexico.

Learn how to stream NASA programming through a variety of platforms including social media.

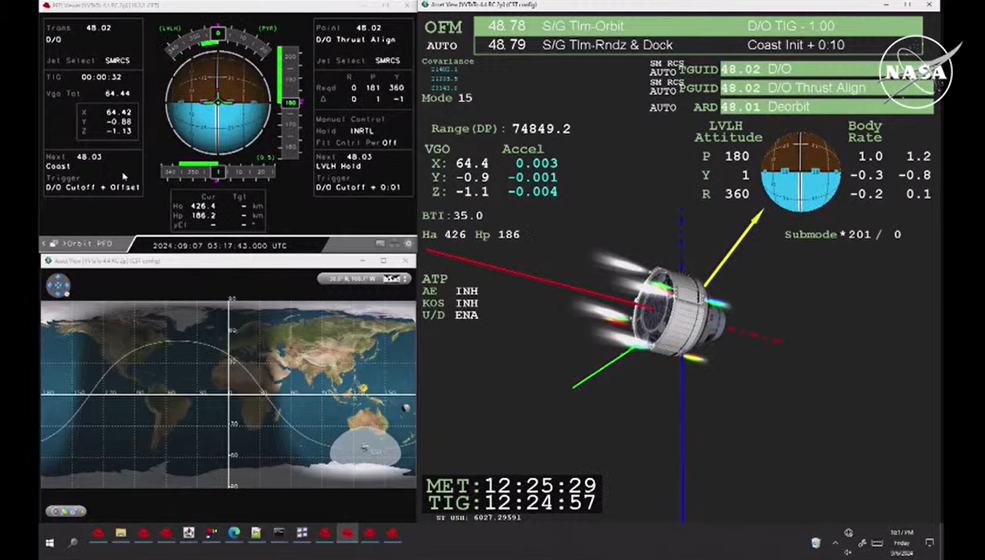

Starliner Completes Deorbit Burn, Readies for Entry Interface

At 11:18 p.m. EDT, Boeing’s uncrewed Starliner spacecraft completed its deorbit burn as expected over the Pacific Ocean. About two and a half minutes later, the spacecraft’s expendable service module separated. The service module provided propulsion and power leading up to the deorbit burn.

NASA’s coverage continues on NASA+, the NASA app, YouTube, and the agency’s website as teams prepare for landing.

The next milestone is in about 15 minutes with entry interface. Starliner will angle itself and its heat shield for re-entry as the spacecraft prepares for a parachute-and-airbag-assisted landing at approximately 12 a.m. Saturday, Sept. 7, at White Sands Space Harbor in New Mexico.

Starliner is the first American-made orbital crew capsule designed to perform a ground landing as a reusable spacecraft. NASA’s Spaceflight Meteorology Group forecasts a few clouds at 8,000 feet and winds out of 100 degrees around 6 knots, peaking to 8 knots, for tonight’s landing.

Learn how to stream NASA programming through a variety of platforms including social media.