NASA’s Commercial Crew Program secured eight crew rotation missions from Boeing and SpaceX – four from each company. The missions will carry astronauts to the International Space Station through 2024. The four additional missions will fly following NASA certification. They fall under the current Commercial Crew Transportation Capability contracts, and bring the total number of crew rotation missions awarded to each provider to six.

The additional flights will allow the commercial partners to plan for all aspects of these missions while fulfilling space station transportation needs. The awards do not include payments at this time.

“Awarding these missions now will provide greater stability for the future space station crew rotation schedule, as well as reduce schedule and financial uncertainty for our providers,” said Phil McAlister, director of NASA’s Commercial Spaceflight Development Division. “The ability to turn on missions as needed to meet the needs of the space station program is an important aspect of the Commercial Crew Program.”

The two commercial spacecraft also will provide a lifeboat capability to allow the astronauts aboard the station to return safely to Earth in an emergency, if necessary.

Returning human launch capabilities to U.S. soil underscores NASA’s commitment to the station and the research that the orbiting laboratory makes possible including the advancement of scientific knowledge off the Earth, for the benefit of those on the Earth and to prepare for future deep space exploration.

The Commercial Crew Program will help NASA get full operational use from the national laboratory for scientific research by increasing the number of astronauts on the space station, and allowing the crew members to dedicate more time to research.

For more details about the missions and the work of the Commercial Crew Program, click here.

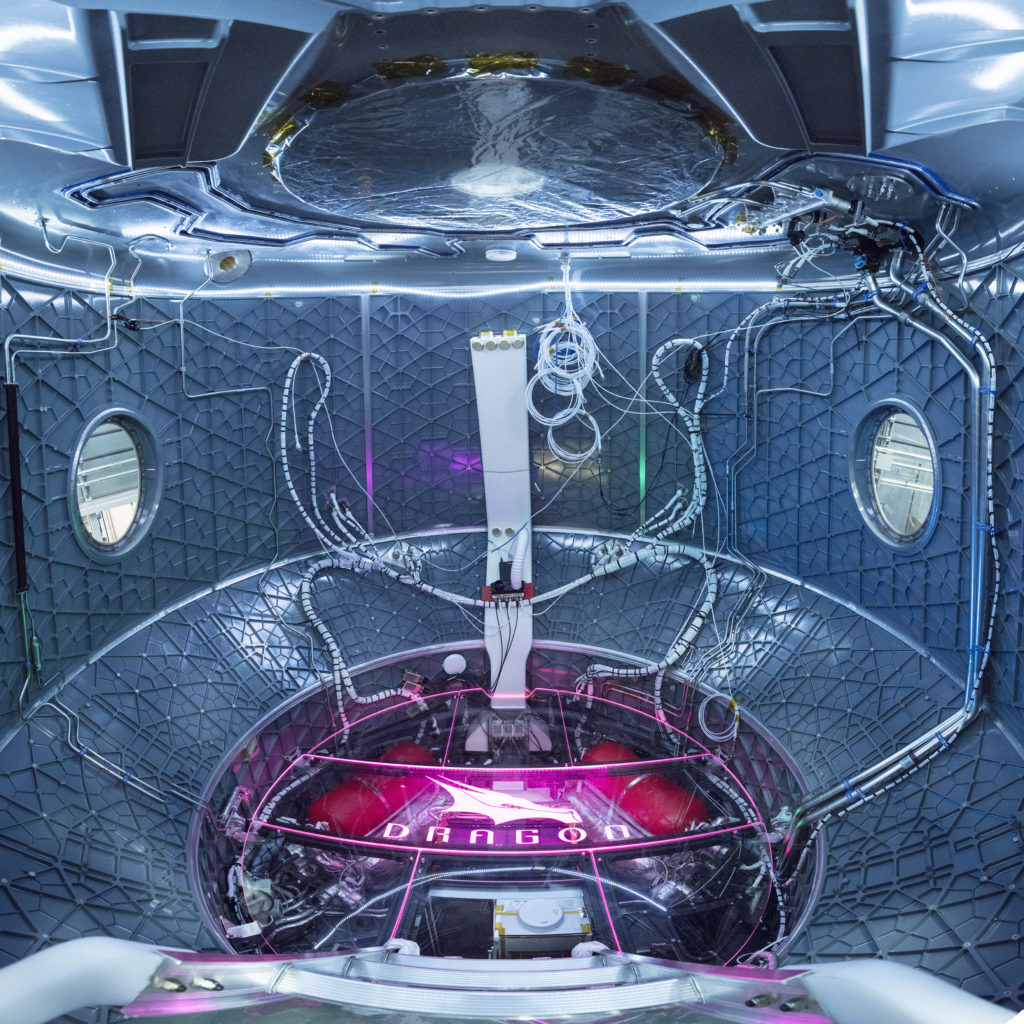

The Environmental Control and Life Support System of a spacecraft provides astronauts with breathing air and handles everything from temperature regulation to removing carbon dioxide as astronauts breathe.

The Environmental Control and Life Support System of a spacecraft provides astronauts with breathing air and handles everything from temperature regulation to removing carbon dioxide as astronauts breathe.

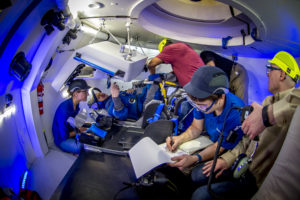

Astronauts heading into orbit aboard Boeing’s Starliner spacecraft will wear lighter and more comfortable spacesuits than earlier suits astronauts wore. The suit capitalizes on historical designs, meets NASA requirements for safety and functionality, and introduces cutting-edge innovations. Boeing unveiled its spacesuit design Wednesday as the company continues to move toward flight tests of its Starliner spacecraft and launch systems that will fly astronauts to the International Space Station.

Astronauts heading into orbit aboard Boeing’s Starliner spacecraft will wear lighter and more comfortable spacesuits than earlier suits astronauts wore. The suit capitalizes on historical designs, meets NASA requirements for safety and functionality, and introduces cutting-edge innovations. Boeing unveiled its spacesuit design Wednesday as the company continues to move toward flight tests of its Starliner spacecraft and launch systems that will fly astronauts to the International Space Station.

Boeing’s Starliner spacecraft will experience a variety of tremendous internal and external forces during missions to and from the International Space Station. When the Starliner launches in 2018, it won’t be the first time the spacecraft has encountered these forces. That is because Boeing built a Structural Test Article that will experience the rigors of spaceflight in a test facility in an effort to prove the design of the spacecraft. The module was built inside the company’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida (top) before it was shipped it across the country to Huntington Beach, California, for testing (right).

Boeing’s Starliner spacecraft will experience a variety of tremendous internal and external forces during missions to and from the International Space Station. When the Starliner launches in 2018, it won’t be the first time the spacecraft has encountered these forces. That is because Boeing built a Structural Test Article that will experience the rigors of spaceflight in a test facility in an effort to prove the design of the spacecraft. The module was built inside the company’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida (top) before it was shipped it across the country to Huntington Beach, California, for testing (right). It joined test versions of the service module, the launch vehicle adapter truss structure and other hardware that make up the upper stage of the United Launch Alliance Atlas V rocket. Testing of the article began shortly after it arrived to Boeing’s Test and Evaluation facility. The first test involved pressurizing the interior of the crew module to 1.5 times the maximum pressure a Starliner spacecraft would face during ascent, orbit, re-entry and landing for missions to and from the International Space Station.

It joined test versions of the service module, the launch vehicle adapter truss structure and other hardware that make up the upper stage of the United Launch Alliance Atlas V rocket. Testing of the article began shortly after it arrived to Boeing’s Test and Evaluation facility. The first test involved pressurizing the interior of the crew module to 1.5 times the maximum pressure a Starliner spacecraft would face during ascent, orbit, re-entry and landing for missions to and from the International Space Station. Boeing’s facilities in southern California are outfitted with numerous test chambers that routinely evaluate spacecraft and other vehicles in a variety of environments to make sure they can handle the demands of flight.

Boeing’s facilities in southern California are outfitted with numerous test chambers that routinely evaluate spacecraft and other vehicles in a variety of environments to make sure they can handle the demands of flight.