SpaceX, NASA and Air Force personnel who will help astronauts out of the SpaceX Crew Dragon spacecraft returning from a mission to the International Space Station have begun practicing for that using a full-size model of the spacecraft. In certain unusual recovery situations, SpaceX may need to work with the U.S. Air Force to send parajumpers to recover astronauts from the capsule in the water. Recently, the Recovery Trainer was lowered into the Indian River Lagoon near NASA’s Kennedy Space Center so Air Force pararescue and others could learn techniques for getting aboard the spacecraft and rescuing the astronauts.

Such rescue practice is typical of all human missions because it gives astronauts and support teams many opportunities to practice and refine the critical steps in safely rescuing the crew in a contingency situation. A number of procedures will be developed and then practiced over time to deal with recoveries in many different conditions.

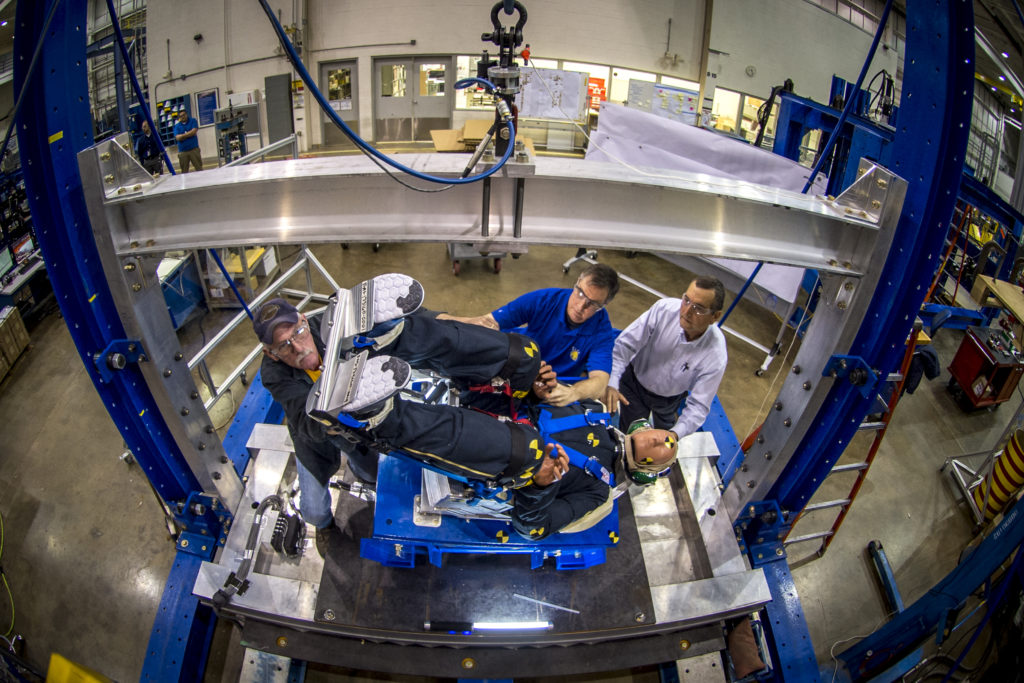

SpaceX is developing the Crew Dragon in partnership with NASA’s Commercial Crew Program to carry astronauts to the International Space Station. The Recovery Trainer was built by SpaceX and subsequently modified by Kennedy’s Prototype Lab to SpaceX specifications. The same dimensions as the outside mold line of a Crew Dragon, it has indicators where thrusters will be and other markings on the exterior. Inside, the crew area matches that of the operational spacecraft and includes an instrument panel.

Bob Behnken and Eric Boe, two of NASA’s four veteran astronauts who supported SpaceX as it refines its crew transportation system designs, checked out the Crew Dragon being used for qualification testing. NASA astronauts routinely travel to industry facilities during spacecraft and mission development to train and offer insights to engineers.

Bob Behnken and Eric Boe, two of NASA’s four veteran astronauts who supported SpaceX as it refines its crew transportation system designs, checked out the Crew Dragon being used for qualification testing. NASA astronauts routinely travel to industry facilities during spacecraft and mission development to train and offer insights to engineers.

Engineers for the first time powered up the CST-100 Starliner spacecraft that will fly Boeing’s inaugural flight test of the next-generation spacecraft. Working inside Boeing’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida, the test team activated the flight avionics system for the Starliner known as Spacecraft 1. The system is the same astronauts will use for all Starliner missions.

Engineers for the first time powered up the CST-100 Starliner spacecraft that will fly Boeing’s inaugural flight test of the next-generation spacecraft. Working inside Boeing’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida, the test team activated the flight avionics system for the Starliner known as Spacecraft 1. The system is the same astronauts will use for all Starliner missions.