The Goal: CCtCap stands for Commercial Crew Transportation Capability. It is a contract for one or more American aerospace companies to complete development of a human space transportation system capable of carrying people into orbit, specifically to transport astronauts to the International Space Station and return them safely to Earth. To be certified to carry NASA astronauts, the systems must meet NASA safety standards. It’s the last step in a cycle of five separate spacecraft transportation development Space Act Agreements and certification contracts NASA began in 2010.

The Goal: CCtCap stands for Commercial Crew Transportation Capability. It is a contract for one or more American aerospace companies to complete development of a human space transportation system capable of carrying people into orbit, specifically to transport astronauts to the International Space Station and return them safely to Earth. To be certified to carry NASA astronauts, the systems must meet NASA safety standards. It’s the last step in a cycle of five separate spacecraft transportation development Space Act Agreements and certification contracts NASA began in 2010.- How it’s Done: NASA’s Commercial Crew Program (CCP) will implement CCtCap in a similar manner used during each previous stage of the development process – as a public-private partnership. The industry partner is responsible for the development of its own spaceflight system, which it will own and operate. NASA’s expert team of engineers and spaceflight specialists are working with the companies and certifying the systems to ensure any new crew transportation system is safe and reliable for NASA astronauts. For previous human spaceflight systems including the space shuttle, NASA designed, owned, and operated the systems, and the agency was responsible for the overall development.

- Buying a Service: Once development is complete, NASA plans to buy a service – simply put, like getting a taxi ride to low-Earth orbit. Because the companies will own and operate the systems, they will be able to sell human space transportation services to other customers in addition to NASA, thereby reducing the costs.

- Innovation: This new process lets industry partners apply innovations and corporate expertise into their designs. NASA provides a top-level set of requirements the companies must meet, but how they meet those requirements is up to them. Each company thoroughly tests its materials and mechanisms to prove its design is sound, and NASA certifies that the systems meet the agency’s requirements.

- Commercial Investment: Industry partners are investing their own resources into the development, too. In this way, NASA and industry share the cost of development and both are invested in and committed to a successful outcome.

- Contract Terms: NASA’s contract, whether with one company or more, will include at least one crewed flight test per company to verify the integrated rocket and spacecraft system can launch, maneuver in orbit, and dock to the space station, as well as validate all its systems perform as expected. Once the test program has been successfully completed and the systems achieve NASA certification, the contractor/s also conduct at least two, and as many as six, crewed missions to the space station, effectively ending the nation’s reliance on foreign providers.

- Award: NASA has not specified a set number of awards under CCtCap. In late August or September, the agency will select the company or companies that will build an operational space transportation system. While the procurement process is ongoing, the agency cannot answer specific questions about the proposals received or the award decision-making process.

- Open Competition: CCtCap is an open competition using FAR-based procedures that will result in a firm fixed-price contract. Any U.S. company could have submitted a proposal for a CCtCap contract. It is not limited to companies that earned previous contracts. However, all companies that submitted proposals should have demonstrated a level of maturity equivalent to the first phase of NASA certification efforts during the agency’s Certification Products Contract (CPC)

- Safe Haven: The spacecraft must be able to serve as a lifeboat, able to safely and quickly evacuate the space station’s crew in an emergency. It also must demonstrate it can serve as a 24-hour safe haven during an emergency in space and be able to stay docked to the station for at least 210 days.

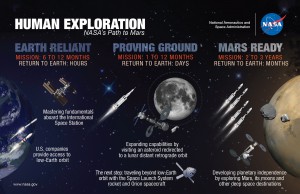

- Journey to Mars: By encouraging private companies to provide human transportation services to and from low-Earth orbit – a region NASA’s been visiting since 1962 – the nation’s space agency can focus on getting the most research and experience out of America’s investment in the International Space Station. NASA also can focus on building spacecraft and rockets for deep space missions, including flights to Mars in the 2030s.

Author: Steven Siceloff

NASA and Commercial Partners Review Summer of Advancements

NASA’s spaceflight experts in the Commercial Crew Program (CCP) met throughout July with aerospace partners to review increasingly advanced designs, elements and systems of the spacecraft and launch vehicles under development as part of the space agency’s Commercial Crew Integrated Capability (CCiCap) and Commercial Crew Development Round 2 (CCDev2) initiatives.

NASA’s spaceflight experts in the Commercial Crew Program (CCP) met throughout July with aerospace partners to review increasingly advanced designs, elements and systems of the spacecraft and launch vehicles under development as part of the space agency’s Commercial Crew Integrated Capability (CCiCap) and Commercial Crew Development Round 2 (CCDev2) initiatives.

“These discussions capitalize on all the aspects of working as partners instead of working solely as a customer and supplier,” said Kathy Lueders, manager of NASA’s Commercial Crew Program. “The partners are innovative in a number of developmental areas. We have a set of detailed criteria drawn up so we can adequately evaluate what they are doing and they can tell us where adjustments fit in with their system’s overall success. It’s exactly what we had in mind when we kicked off this effort four years ago.”

Read details of today’s news here.

Robotic Arm Tech Aids Surgical Robot KidsArm

The gift of space-inspired robotics now goes beyond toys. They are lending a helping arm to pediatric doctors for children who require intensive surgical care.

The same companies which developed the robotic arms that helped astronauts build the International Space Station have now created a new research platform. Called KidsArm, this robot allows surgeons to quickly navigate to surgical sites in the body. It has an advanced imaging and control system that makes it extremely precise, and it is designed to explore the potential for automating certain demanding tasks in minimally invasive pediatric surgery — a challenge before without the tool’s assistance.

150 Companies in 37 States

Art of the Spacesuit

The modern spacesuit can do a lot of things a full spacecraft can do, though for not nearly as long. Providing oxygen to breath, plus cool and warm air for comfort, a space suit serves in many ways as a personal spacecraft. It also acts as a storage bin of sorts, with pockets all over the garment to hold tools, notes and the occasional family photo. Some of NASA’s aerospace industry partners are designing suits to handle their needs. NASA teams are working on the robust designs that will keep astronauts safe and healthy during walks along the Martian surface.

With a new era of advanced spacecraft on the horizon, what would you like to see in a spacesuit you put on? What memento would you absolutely have to take with you stuffed in a pocket?

What Would You Do On Mars?

NASA’s human exploration pathway leads to Mars. Our Commercial Crew Program is just the beginning, and the new Mars 2020 rover is one of the upcoming steps, but think about that finish line today and consider what you would do if you landed on the Red Planet. What Mars features would you want to explore? What would you hope to discover? What might you leave behind? What would you bring home?

What would you take with you – aside from oxygen, water and radiation protection? Because Mars is as far away as it is, a mission would last two to three years, with several months on the surface, so there’ll be lots of time before packing up and heading back to Earth. Are you going to look out the window or is there an exploration or construction project on your mind? If you need some help kick-starting your mind on these aspects, have a look at our Mars site and note the pic below of experimental set-ups being tried out in Earth environments with an eye toward crew needs on Mars.

NASA Partners Punctuate Summer with Spacecraft Development Advances

Spacecraft and rocket development is on pace this summer for NASA’s aerospace industry partners for the agency’s Commercial Crew Program as they progress through systems testing, review boards and quarterly sessions under their Space Act Agreements with the agency.

NASA engineers and specialists continue their review of the progress as the agency and partners move ahead with plans to develop the first American spacecraft designed to carry people into space since the space shuttle.

“Our partners are making great progress as they refine their systems for safe, reliable and cost-effective spaceflight,” said Kathy Lueders, manager of NASA’s Commercial Crew Program. “It is extremely impressive to hear and see the interchange between the company and NASA engineering teams as they delve into the very details of the systems that help assure the safety of passengers.”

Apollo 11@45: Liftoff to Inspiration

Arguably, no single event did more to inspire people around the world than the first moon landing by the crew of Apollo 11. This includes numerous astronauts, NASA engineers, and contractors inspired to go through rigorous scientific and engineering academic tracts after sitting in the living room of their house as children watching the fuzzy black-and-white image of Neil Armstrong move down the ladder of the lunar module and take humanity’s first steps onto another world.

Arguably, no single event did more to inspire people around the world than the first moon landing by the crew of Apollo 11. This includes numerous astronauts, NASA engineers, and contractors inspired to go through rigorous scientific and engineering academic tracts after sitting in the living room of their house as children watching the fuzzy black-and-white image of Neil Armstrong move down the ladder of the lunar module and take humanity’s first steps onto another world.

That mission lifted off from Kennedy Space Center 45 years ago this morning with the moon landing and first steps taken four days later. (You can watch NASA’s launch videos here)

Mike Good, a veteran astronaut who works with the Commercial Crew Program and whose missions include spacewalks to repair NASA’s Hubble Space Telescope, put it this way when asked why he became an astronaut:

“I certainly remember as a little kid being influenced and inspired by the landing on the moon. I was 7 years old and watched it on a black-and-white TV in my living room. Like all the kids and everybody else, I thought that it was pretty cool. Then as I worked through school and got into college, I became interested in engineering. I made the decision to go into aerospace engineering in 1981, which was the first year that the space shuttle flew, so that definitely had an influence on me, too. I watched that and said, ‘You know, this is something that I’d like to be a part of.’ I didn’t necessarily think I was going to be an astronaut, but it was an industry that I wanted to be in. After college I went on to fly for the Air Force, and I was able to put the flying and engineering together, which are two things that I liked to do. After flying fighters for a while, I got to go through the Air Force’s test pilot school, which is really where you get to test new airplanes and weapons systems. From there, it was just kind of a natural progression to work toward the astronaut program. I put in a couple applications and finally got a call to come join.”

The Brains of the Countdown

Every mission into space, whether carrying a crew or lofting a satellite or probe, is overseen by a collection of specialists who make sure everything is A-OK with the rocket and spacecraft through liftoff, ascent and beyond. At NASA’s Kennedy Space Center in Florida, the Launch Control Center was the space agency’s answer to the gargantuan demands of processing and testing the Saturn V rockets and Apollo spacecraft that would carry astronauts to the moon. The aerospace industry partners of NASA’s Commercial Crew Program will use control centers based on the unique needs of their systems and the capabilities of today’s computers and automation. With the 45th anniversary of Apollo 11’s liftoff from Kennedy tomorrow, here’s a look at what went into designing, building and operating the LCC.

Throwback Thursday – A Flag Awaits

This American flag was taken to the International Space Station in 2011 on STS-135, the final mission of the space shuttle. Flown on the first space shuttle mission in 1981, the flag is to be awarded to the first crew of astronauts to launch from U.S. soil to the orbiting laboratory. NASA’s Commercial Crew Program is working with aerospace partners to make that flight happen by the end of 2017.

This American flag was taken to the International Space Station in 2011 on STS-135, the final mission of the space shuttle. Flown on the first space shuttle mission in 1981, the flag is to be awarded to the first crew of astronauts to launch from U.S. soil to the orbiting laboratory. NASA’s Commercial Crew Program is working with aerospace partners to make that flight happen by the end of 2017.