The first new Crew Access Tower at Cape

The first new Crew Access Tower at Cape

Canaveral Air Force Station in Florida since the Apollo

Canaveral Air Force Station in Florida since the Apollo  era will take shape at Space Launch Complex-41 in the coming days as workers moved the first two tiers from a nearby construction yard to the pad surface. The tiers will be lifted into place atop each other at the foot of the launch pad starting next week.

era will take shape at Space Launch Complex-41 in the coming days as workers moved the first two tiers from a nearby construction yard to the pad surface. The tiers will be lifted into place atop each other at the foot of the launch pad starting next week.

Boeing and United Launch Alliance are building the tower which is a critical element for the launch pad as it is converted from a pad that serves only uncrewed missions to a complex that can safely accommodate the needs of flight crews along with their ground support teams for CST-100 Starliner missions. The Starliner is under development in partnership with NASA’s Commercial Crew Program, along with the SpaceX Crew Dragon, to take astronauts to the International Space Station from Florida’s Space Coast.

Designed with modern data systems, communications and power networks integrated and protected from blast and vibration, plus an elevator, the Crew Access Tower has been built with several features only a fully suited astronaut could appreciate, such as wider walkways, snag-free railings and corners that are easy to navigate without running into someone. The tower will also be equipped with slide wire baskets for emergency evacuation to a staged blast-resistant vehicle.

The segments were assembled about four miles away from the launch pad so workers wouldn’t be idled by launch preps for United Launch Alliance Atlas V rockets. The tower will be stacked just to the side of the hard stand at SLC-41 where the boosters lift off. It will take seven tiers to complete the more than 200-foot-tall tower. A swing-out walkway bridge will be added later to connect the tower to the hatch of the Starliner so astronauts can climb aboard the ship as it stands at the pad before launch.

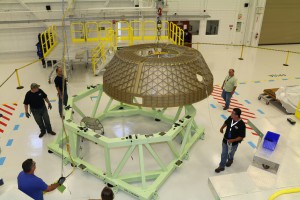

The tower construction marks the latest in a quick succession of events for Boeing’s Starliner program. The company opened the Commercial Crew and Cargo Processing Facility last week for use as the Starliner production and processing base and just completed the mural on the front of the building showing the spacecraft orbiting above Florida. The upper and lower dome assemblies arrived earlier this year for the Starliner’s Structural Test Article which is being built and processed as a pathfinder for the program and will be put together just as an operational spacecraft would before it goes into exhaustive testing to the prove the design.

Astronauts and ground support teams are bobbing in a unique pool in Houston to find out the best way to exit a spacecraft after coming back to Earth and landing in the water. The rehearsals involve a test version of the Orion spacecraft, which NASA will use for deep space missions to an asteroid and Mars, but the evaluations also apply well to recovery planning for companies developing spacecraft for NASA’s Commercial Crew Program. The program will return crew launch capabilities from the U.S. for missions to the International Space Station.

Astronauts and ground support teams are bobbing in a unique pool in Houston to find out the best way to exit a spacecraft after coming back to Earth and landing in the water. The rehearsals involve a test version of the Orion spacecraft, which NASA will use for deep space missions to an asteroid and Mars, but the evaluations also apply well to recovery planning for companies developing spacecraft for NASA’s Commercial Crew Program. The program will return crew launch capabilities from the U.S. for missions to the International Space Station.

A year after awarding landmark contracts to Boeing and SpaceX to build a new generation of human-rated space systems, NASA’s Commercial Crew Program has made great strides to re-establish America’s capability to launch astronauts to the International Space Station.

A year after awarding landmark contracts to Boeing and SpaceX to build a new generation of human-rated space systems, NASA’s Commercial Crew Program has made great strides to re-establish America’s capability to launch astronauts to the International Space Station.

The first new Crew Access Tower at Cape

The first new Crew Access Tower at Cape

Canaveral Air Force Station in Florida since the Apollo

Canaveral Air Force Station in Florida since the Apollo  era will take shape at Space Launch Complex-41 in the coming days as workers moved the first two tiers from a nearby construction yard to the pad surface. The tiers will be lifted into place atop each other at the foot of the launch pad starting next week.

era will take shape at Space Launch Complex-41 in the coming days as workers moved the first two tiers from a nearby construction yard to the pad surface. The tiers will be lifted into place atop each other at the foot of the launch pad starting next week.

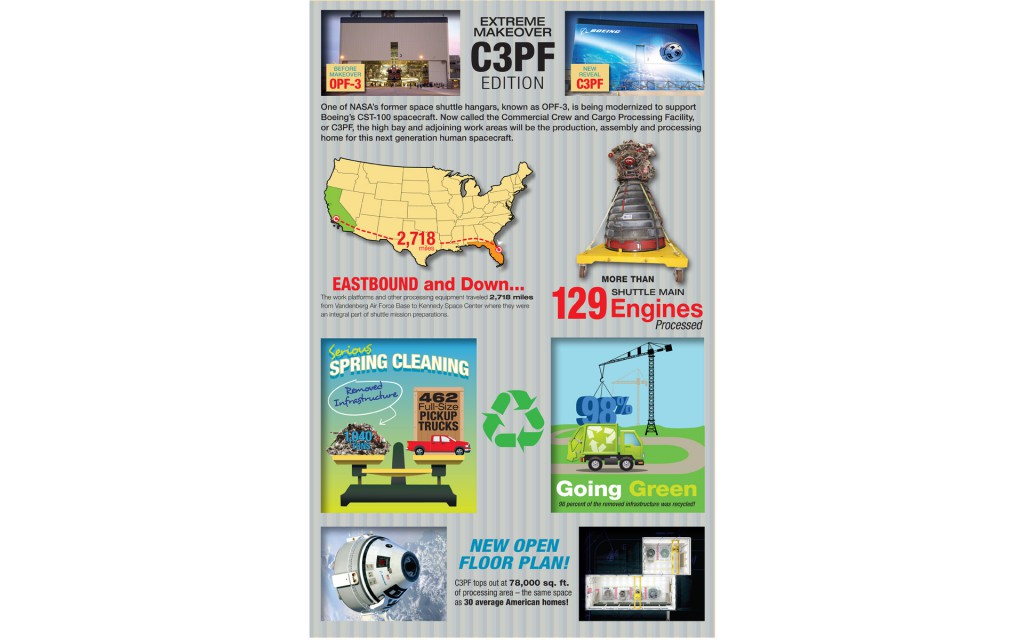

Boeing is unveiling a new name for its CST-100 spacecraft along with the factory floor space where the structural test article is already coming together during a ceremony at the Commercial Crew and Cargo Processing Facility here at NASA’s Kennedy Space Center in Florida. The event begins at 10 a.m. ET and will air on NASA TV, which you can watch here on the blog or in a separate window. The high bay of the C3PF, which used to be called Orbiter Processing Facility-3, is still under construction but a new mural over the front of the building showcases the facility’s role in building and processing a new spacecraft for the next generation of human-rated spaceflight.

Boeing is unveiling a new name for its CST-100 spacecraft along with the factory floor space where the structural test article is already coming together during a ceremony at the Commercial Crew and Cargo Processing Facility here at NASA’s Kennedy Space Center in Florida. The event begins at 10 a.m. ET and will air on NASA TV, which you can watch here on the blog or in a separate window. The high bay of the C3PF, which used to be called Orbiter Processing Facility-3, is still under construction but a new mural over the front of the building showcases the facility’s role in building and processing a new spacecraft for the next generation of human-rated spaceflight.

More than 1,040 tons of steel and aluminum platforms, work stands and other hardware were removed from the building’s high bay to make room for the specialized equipment to allow an assembly line for CST-100 crew and service modules. Massive overhead cranes in the building capable of lifting up to 30 tons remain in place and are critical in moving spacecraft and heavy equipment into different areas as the CST-100 is built up from pressure vessel to operational spacecraft.

More than 1,040 tons of steel and aluminum platforms, work stands and other hardware were removed from the building’s high bay to make room for the specialized equipment to allow an assembly line for CST-100 crew and service modules. Massive overhead cranes in the building capable of lifting up to 30 tons remain in place and are critical in moving spacecraft and heavy equipment into different areas as the CST-100 is built up from pressure vessel to operational spacecraft.