Some of the best works of art come from children who are only limited by their imaginations, like the more than 150 young explorers from across the country who submitted artwork depicting human spaceflight as they see it. Sixteen masterpieces were chosen to be included in the Commercial Crew Program’s 2016 Children’s Artwork Calendar, which is now available for download here. We offer a huge “thank you!” to all the explorers, ranging in age from four to 12, who submitted their work and hope that everyone will enjoy and use this calendar next year.

Some of the best works of art come from children who are only limited by their imaginations, like the more than 150 young explorers from across the country who submitted artwork depicting human spaceflight as they see it. Sixteen masterpieces were chosen to be included in the Commercial Crew Program’s 2016 Children’s Artwork Calendar, which is now available for download here. We offer a huge “thank you!” to all the explorers, ranging in age from four to 12, who submitted their work and hope that everyone will enjoy and use this calendar next year.

Category: Boeing

Seeking Sky Walkers

Have you ever wanted to explore to a galaxy far, far away? Is the Force strong in you? NASA seeks sky walkers to join the astronaut alliance. Learn more, at www.nasa.gov/astronauts.

Astronauts Celebrate With Builders Topping of Crew Access Tower

Four astronauts training for test flights with NASA’s Commercial Crew program joined the festivities at Space Launch Complex 41 Thursday morning as one of the highest steel beams was placed on the Crew Access Tower during a “topping off” ceremony with United Launch Alliance, Boeing and Hensel Phelps at the Cape Canaveral Air Force Station launch site in Florida.

Four astronauts training for test flights with NASA’s Commercial Crew program joined the festivities at Space Launch Complex 41 Thursday morning as one of the highest steel beams was placed on the Crew Access Tower during a “topping off” ceremony with United Launch Alliance, Boeing and Hensel Phelps at the Cape Canaveral Air Force Station launch site in Florida.

“It’s really an honor to get down here. We’re humbled to be a part of launching rockets for the United States again,” said Doug Hurley, a veteran of space shuttle missions and one of the four chosen to work closely with partners of NASA’s Commercial Crew Program during development, testing and training. Bob Behnken, Eric Boe and Suni Williams were also selected and took part in the employee-focused event.

“It’s amazing how many people it takes to get us into space,” Boe said.

“It’s amazing how many people it takes to get us into space,” Boe said.

A large crowd of employees from numerous companies gathered mid-morning to sign the 650-pound beam and watch a crane lift it into place atop the 200-foot-tall Crew Access Tower constructed over the past year. It was built in segments complete with stairs, cable trays and other fittings a few miles from the launch pad, then those segments were stacked on top of each other to form the tower. The Crew Access Arm and White Room the astronauts looked over today will be attached to the tower after several months’ of testing and fit checks.

A large crowd of employees from numerous companies gathered mid-morning to sign the 650-pound beam and watch a crane lift it into place atop the 200-foot-tall Crew Access Tower constructed over the past year. It was built in segments complete with stairs, cable trays and other fittings a few miles from the launch pad, then those segments were stacked on top of each other to form the tower. The Crew Access Arm and White Room the astronauts looked over today will be attached to the tower after several months’ of testing and fit checks.

“We’ve poured 1,000 cubic yards of concrete and mounted nearly 1 million pounds of steel, and we’ve done it in spectacular fashion,” said Howard Biegler, launch operations lead for ULA’s Human Launch Services.

“We’ve poured 1,000 cubic yards of concrete and mounted nearly 1 million pounds of steel, and we’ve done it in spectacular fashion,” said Howard Biegler, launch operations lead for ULA’s Human Launch Services.

Employees were asked to sign the beam before it was lifted into place and welded to the top of the tower.

“Today you are part of history,” said Kathy Lueders, program manager of NASA’s Commercial Crew Program. “Stop and enjoy this moment. I hope everyone has been able to write their name on the beam because you are part of the critical safety network that is making this all possible.”

Prior to the ceremony at SLC-41, the astronauts toured the White Room and Crew Access Arm undergoing testing at a construction yard near Kennedy Space Center. The White Room will be the stepping off point to space for astronauts as they board a Boeing CST-100 Starliner for liftoff on a ULA Atlas V rocket. Designed as a clean area to keep contaminants out of the spacecraft and off the astronauts’ suits, white rooms are the place where technicians make last-minute additions to the spacesuit and make sure everything is ready to flight as the flight crew climbs inside for launch. White rooms have always been a part of NASA’s human spaceflight efforts, from Mercury to Gemini and Apollo to the space shuttle.

“This is the last thing that whoever flies the Starliner is going to see before they go into space,” Hurley told the workers who built the structures.

Boeing and SpaceX are developing a new generation of spacecraft to carry astronauts to the International Space Station beginning in 2017. Both companies are also deep into construction and modification of launch facilities at NASA’s Kennedy Space Center in Florida to safely host astronaut crews as they launch from American soil for the first time since 2011. Designs for launch facilities have been confirmed through NASA panels and in-depth examinations.

For Boeing, launching from SLC-41 meant building the Crew Access Tower, the first crew-focused structure at Cape Canaveral since Apollo 7. SpaceX is modifying historic Launch Pad 39A for its commercial crew missions on the Crew Dragon spacecraft launching on its Falcon 9 rockets. It also will have a White Room tailored to its designs that will offer astronauts and ground crew safety as they board and a way to leave the spacecraft in a hurry before launch in the unlikely event of an emergency. Photo credits: NASA/Kim Shiflett

Starliner Structural Test Article Assembly Features in Tour

News media and NASA Social participants were treated to a close-up look at the structural test article for Boeing’s CST-100 Starliner spacecraft as they toured the company’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center Tuesday afternoon.

Danom Buck, manager of the Manufacturing and Engineering team, said the test version will be built using the same techniques and processes planned for the operational spacecraft that will carry astronauts to the International Space Station for NASA’s Commercial Crew Program. Two flight tests, one without a crew and the second with a crew aboard, will be performed before the company begins operational flights to the station that will allow for an extra resident there and double the amount of astronaut time devoted to science.

Commercial Crew Showcased on Tour

Commercial Crew team members with NASA and our aerospace industry partners showed what a season of advances has meant for the launch sites where NASA astronauts will lift off on missions to the International Space Station in the near future.

Commercial Crew team members with NASA and our aerospace industry partners showed what a season of advances has meant for the launch sites where NASA astronauts will lift off on missions to the International Space Station in the near future.

At Launch Pad 39A, Carol Scott, who works technical integration for NASA’s Commercial Crew Program, showed news media and NASA Social participants the new look SpaceX is applying to the launch complex to make it suit the company’s needs for Crew Dragon missions.

Boeing and United Launch Alliance spent the last couple months building a new Crew Access Tower at Space Launch Complex 41, the place where Boeing’s CST-100 Starliner will fly from on missions with astronauts. NASA’s Steve Payne, who works in Launch Integration, and ULA’s Howard Biegler, Launch Operations lead of Human Launch Service, detailed the work that went into constructing the tower that will contain all the systems needed to safely support human crews and ground support staff for a Starliner launch.

The progress is important for NASA because it will restore American capabilities to launch astronauts to low-Earth orbit. For the orbiting laboratory of the space station, the flights will increase the crew by one and double the amount of time astronauts can devote to cutting-edge research to answer the vexing issues of a journey to Mars and to conduct science off the Earth for all those on the Earth.

Commercial Crew Across America: California and Washington

Work taking place in Sacramento, California, and Redmond, Washington, will offer a critical boost to Boeing’s CST-100 Starliner spacecraft as it heads to the International Space Station thanks to Aerojet Rocketdyne, which is producing the propulsion system for the Starliner’s service module and maneuvering jets. The main thrusters and system assembly originate in Sacramento, while the steering thrusters on the capsule are manufactured in Redmond.

Work taking place in Sacramento, California, and Redmond, Washington, will offer a critical boost to Boeing’s CST-100 Starliner spacecraft as it heads to the International Space Station thanks to Aerojet Rocketdyne, which is producing the propulsion system for the Starliner’s service module and maneuvering jets. The main thrusters and system assembly originate in Sacramento, while the steering thrusters on the capsule are manufactured in Redmond.

In the words of Aerojet Rocketdyne, “The Starliner service module propulsion system provides integrated launch abort capability on the pad and during ascent along with all propulsion needs during a nominal flight—from launch vehicle separation, docking and undocking from the ISS, and through separation of the crew and service modules when the spacecraft begins to re-enter the Earth’s atmosphere.”

The thrusters also are crucial to the Starliner’s abort system that would ignite in the unlikely event of a launch pad emergency or during the climb into orbit. Each service module will include four 40,000-pound thrusters designed to push the spacecraft and its crew out of harm’s way. They’ll be integrated into the Starliner’s service module inside Boeing’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida prior to an uncrewed and then crew flight test to the space station. Read more here.

Astronauts Try Out Crew Dragon Display at SpaceX

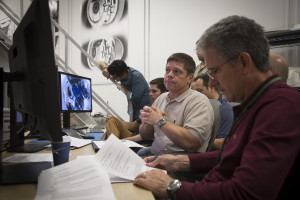

Commercial crew astronauts Doug Hurley, Sunita “Suni” Williams and Bob Behnken had the opportunity to evaluate the displays in the Crew Dragon spacecraft at SpaceX’s Hawthorne, California, headquarters.

Commercial crew astronauts Doug Hurley, Sunita “Suni” Williams and Bob Behnken had the opportunity to evaluate the displays in the Crew Dragon spacecraft at SpaceX’s Hawthorne, California, headquarters.

Hurley, Williams and Behnken are three of four astronauts who were selected to be the first to train to fly to space aboard commercial spacecraft as part of the NASA’s Commercial Crew Program. NASA will decide at a later date which astronauts will fly aboard which spacecraft – SpaceX Crew Dragon and the Boeing CST-100 Starliner. See more photos in Commercial Crew’s Flickr album here.

New Rides Worthy of the New Generation

The astronauts chosen for the next class of explorers will come in to the agency at a time when a new era of spacecraft crosses from design screens and test flights to operational missions. For the first time, there will be three spacecraft and rockets launching humans from Florida’s Space Coast: two commercial crew spacecraft currently in development by U.S. companies, and NASA’s Space Launch System rocket and Orion deep-space exploration vehicle.

The astronauts chosen for the next class of explorers will come in to the agency at a time when a new era of spacecraft crosses from design screens and test flights to operational missions. For the first time, there will be three spacecraft and rockets launching humans from Florida’s Space Coast: two commercial crew spacecraft currently in development by U.S. companies, and NASA’s Space Launch System rocket and Orion deep-space exploration vehicle.

Today, we feature Boeing’s CST-100 Starliner, which along with the SpaceX Crew Dragon, is one of the two spacecraft under development in partnerships with NASA’s Commercial Crew Program to take astronauts to the International Space Station. Although it has a familiar shape, the new spacecraft is more advanced from top to bottom than anything that has flown to date. From advanced avionics and a launch abort system to a spacious cabin and the ability to take both astronauts and cargo on the same vehicle, the Starliner is expected to provide a safe, reliable, and cost-effective transportation from America to the space station.

If you think you have what it takes to fly this new generation of spacecraft, NASA will start taking applications Dec. 14 for its next astronaut class.

Happy Anniversary Apollo 4!

The Apollo spacecraft launched on the first all-up test flight of the Saturn V 48 years ago today to confirm launch loads and dynamic characteristics of the systems that would carry astronauts to the surface of the moon. The flight proved aspects of the Apollo heat shield and re-entry operations.

The Apollo spacecraft launched on the first all-up test flight of the Saturn V 48 years ago today to confirm launch loads and dynamic characteristics of the systems that would carry astronauts to the surface of the moon. The flight proved aspects of the Apollo heat shield and re-entry operations.

Two years from now, at the 50th anniversary of that unpiloted Apollo 4 mission, as part of NASA’s Commercial Crew Program, Boeing’s CST-100 Starliner and the SpaceX Crew Dragon spacecraft will have undergone unpiloted flight tests to confirm their designs.

Construction Tops Off Crew Access Tower at SLC-41

It took only 35 days to build the main column of a new fixture to the skyline along the Florida Space Coast. The 200-foot-tall Crew Access Tower at Cape Canaveral Air Force Station in Florida will meet the unique needs of astronauts and ground crews at Space Launch Complex 41, or SLC-41, where Boeing will launch its CST-100 Starliner spacecraft on Atlas V rockets operated by United Launch Alliance, also known as ULA. Read all the details here. Photos by NASA/Kim Shiflett (top) and Daniel Casper (right).