NASA and Boeing teams are preparing for a flight test no earlier than mid-April in which the Starliner spacecraft will carry two NASA astronauts to the International Space Station.

Teams have made significant progress in resolving technical issues identified during the agency’s flight certification process. Following a successful drop test earlier this month in which recent modifications to Starliner’s parachute system were validated, NASA and Boeing are working to perform final analysis of the test data and complete overall system certification ahead of Starliner’s first crewed flight. This standard NASA process is designed to independently verify Starliner’s parachute system meets crew safety requirements and is expected to continue over the next six to eight weeks.

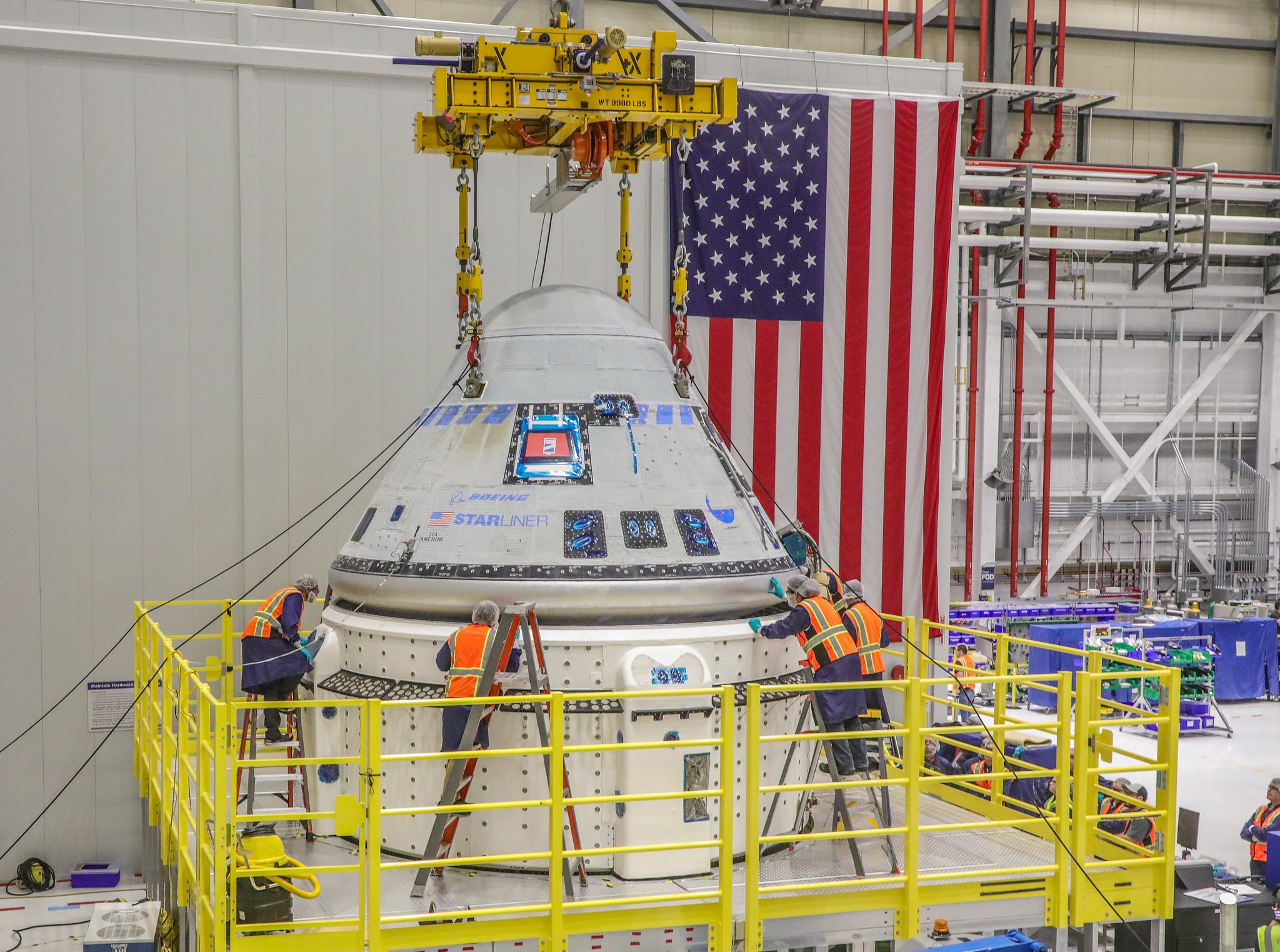

Meanwhile, Boeing completed removal of P213 tape that may have posed a flammability risk in certain environmental conditions. Boeing removed more than 17 pounds, or roughly 4,300 feet, of the material from the Starliner crew module. For areas in which removal of the tape carried an increased risk to Starliner hardware, Boeing applied tested remediation techniques such as overwrapping the P213 tape with another non-flammable, chafe-resistant tape, and installing fire breaks on wire harnesses. The agency worked to clarify the properties and safe usage guidance relative to P213 tape in the NASA Materials Usage Agreements database to prevent a similar misapplication from occurring across industry in the future.

Additionally, major integrated flight operations exercises are underway. Mission support teams recently completed a two-day undock to landing mission dress rehearsal with recovery personnel on the ground at White Sands Missile Range in New Mexico. Teams simulated Crew Flight Test procedures and spacecraft sequences starting with pre-undock powerup and continuing through undock, entry, landing, and crew recovery. The exercise provided an additional training opportunity for NASA and Boeing to practice Starliner’s return to Earth in a high-fidelity environment before the flight.

Teams from ULA (United Launch Alliance) are preparing the Atlas V rocket hardware for processing and spacecraft integration. Boeing is targeting completion of Starliner assembly at the end of January. The upgraded parachutes were delivered and installed on the spacecraft, along with Starliner’s forward heat shield and ascent cover. Prior to fueling operations, following final installation of thermal protection system blankets and internal closeout work, Boeing will begin flowing a nitrogen purge into the Starliner’s service module to ensure ambient moisture does not permeate into the propulsion isolation or active thermal control system valves. In the weeks ahead, NASA and Boeing will work to identify any remaining work before loading Starliner propellant.

The next couple of months teams will:

- work to complete overall Crew Flight Test certification;

- put the finishing touches on the Starliner spacecraft, which is already joined to its service module;

- run simulations of operational conditions to rehearse every phase of the mission with the crew, flight controllers, and ground operations teams;

- fuel the spacecraft with propellants for its onboard thrusters for in-space maneuvering;

- stack the ULA Atlas V rocket and Starliner spacecraft before rolling them to the pad at Space Launch Complex-41 at Cape Canaveral Space Force Station in Florida;

- and work through detailed systems reviews, culminating with a flight readiness review in the days before launch to verify the system and teams are ready.

Starliner’s Crew Flight Test will launch NASA astronauts Butch Wilmore and Suni Williams to the orbiting laboratory for a stay of one to two weeks before returning them to a landing in the southwest United States. The mission will mirror the tasks of regular crew rotation flights for Boeing’s Starliner under contracts with NASA’s Commercial Crew Program.

Follow the commercial crew blog or Crew Flight Test mission blog for the latest information on Starliner’s progress toward launch. Details about the mission and NASA’s Commercial Crew Program can be found by following the commercial crew blog, X, and Facebook.

NASA and its mission partners are gearing up for a busy 2023 with crew launches and returns from the International Space Station. NASA worked closely with its international partners and commercial crew providers, Boeing and SpaceX, to secure new target launch dates for the upcoming flights that are optimal for space station needs.

NASA and its mission partners are gearing up for a busy 2023 with crew launches and returns from the International Space Station. NASA worked closely with its international partners and commercial crew providers, Boeing and SpaceX, to secure new target launch dates for the upcoming flights that are optimal for space station needs.