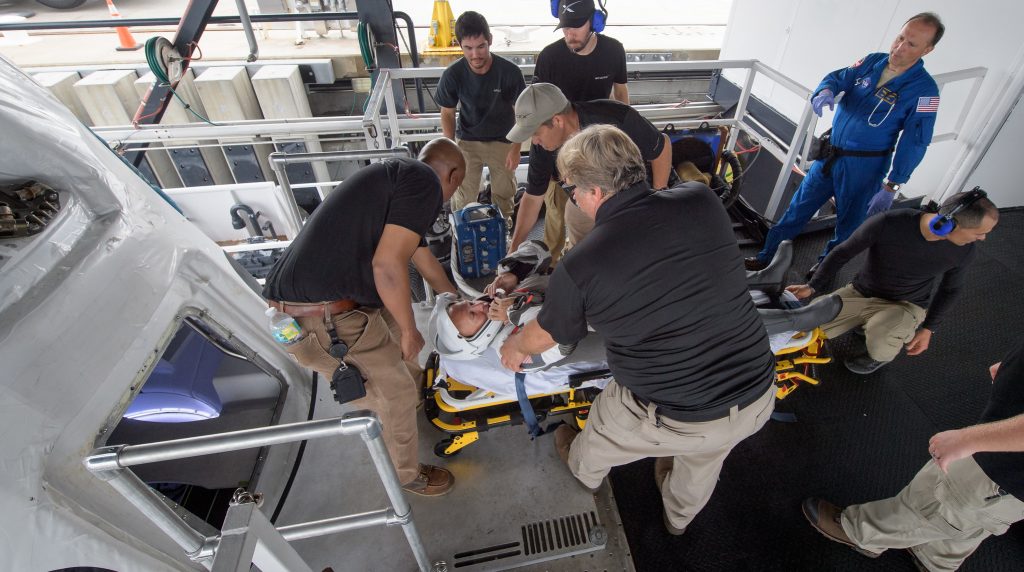

NASA and SpaceX conducted a formal verification of the company’s emergency escape, or egress, system at Kennedy Space Center’s Launch Complex 39A in Florida on Sept. 18, 2019. NASA astronauts Bob Behnken and Shannon Walker participated in the exercise to verify the crew can safely and swiftly evacuate from the launch pad in the unlikely event of an emergency before liftoff of SpaceX’s first crewed flight test, called Demo-2.

“This demonstration allowed all the various teams responsible for ground operations, system design, ground safety and emergency management to observe and verify the system is ready for operational use,” said Steve Payne, launch operations integrator for the agency’s Commercial Crew Program. “It’s a system we hope we never have to use, but we have to be prepared for every scenario.”

During the exercise, Behnken and Walker demonstrated two escape methods to show the crew could leave the 265-foot-level of the launch tower quickly. One method was an expedited non-emergency egress, where the crew started at the end of the crew access arm, called the white room, as if they just exited the capsule, and descended the crew access tower by taking the elevator to the base of the launch pad. Then, they were picked up by the pad team to be returned to crew quarters.

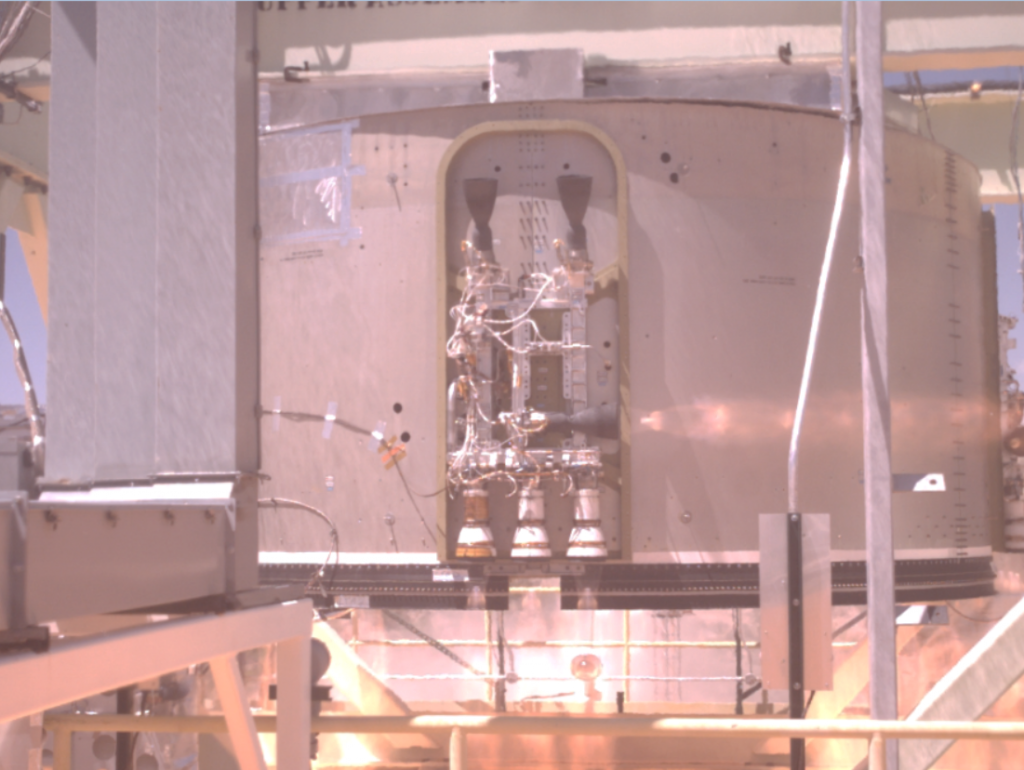

The other method involved an emergency egress, where the crew and pad team started at the crew access arm and escape to the ground using the slidewire baskets, with all alarms and fire suppression systems activated. From there, they boarded an armored vehicle that took them to safety.

“Safety of crew members is the top priority,” Walker said. “This was a great opportunity to test the emergency egress system and procedures on the pad.”

SpaceX provided a demonstration of activating alarms and beacons, putting on emergency breathing air bottles and activating the water deluge system on the crew access level, followed by egress from the white room. The astronauts also practiced loading into the baskets. The release mechanisms were also tested, and a weighted empty basket was sent down the length of the slidewire cable to the landing area.

The slidewire baskets have had a number of design improvements since they were used during the shuttle era. A new braking system was added that regulates the speed as astronauts descend the slidewire, which makes for a smoother ride for the crew. Adjustments to the system have also made dismounting the slidewire baskets much easier than with the previous design.

Also, the platform used for emergency escape on the tower was relocated and reinstalled to the 265-foot-level, up 70 feet from its original shuttle-era location, in order to accommodate a taller launch vehicle.

“If the emergency egress system were ever to be needed to escape from a hazardous event, we want to have complete confidence that it will operate as designed and get our flight crew and pad personnel off the tower quickly and safely,” Payne said.

The verification team also included personnel from the Astronaut Office at NASA’s Johnson Space Center in Houston, NASA Flight Surgeons, SpaceX systems engineers, Kennedy Aero Medical, Commercial Crew Program Safety, and other observers.

“Each time today when we headed down the crew access arm, I couldn’t help but think about what it will be like to strap into Dragon on launch day,” Behnken said. “It’s exciting to have this verification test behind us on our way to the SpaceX Demo-2 mission.”

As commercial crew providers SpaceX and Boeing begin to make regular flights to the space station, NASA will continue to advance its mission to go beyond low-Earth orbit and establish a human presence on the Moon with the ultimate goal of sending astronauts to Mars.

Also, don’t forget to check out the NASA exhibits at Essence Fest and the Audubon Institute’s Aquarium if you are in New Orleans this weekend.

Also, don’t forget to check out the NASA exhibits at Essence Fest and the Audubon Institute’s Aquarium if you are in New Orleans this weekend.